If you’re a woodworking enthusiast or a professional craftsman, finding the right bench vise is crucial to achieving precision and durability in your projects. A sturdy and reliable vise can make all the difference when it comes to securely holding your workpieces, allowing you to focus on the finer details of your craftsmanship.

In this guide, we’ll help you navigate the best bench vises of 2025, including popular models like the Forward CR40A, Wilton 880M, WORKPRO dual-jaw mini, PONY 5-inch, and VEVOR 6-inch.

When selecting a bench vise, there are several key factors to consider. From the quality of materials and jaw options to throat depth and swivel capabilities, each feature plays a significant role in how well the vise will serve your needs.

This guide will break down the strengths and weaknesses of each model, helping you identify which vise aligns with your specific projects and budget.

Whether you’re tackling intricate detailing or simple assembly tasks, the right bench vise can enhance your woodworking experience. As we delve into our top picks, you’ll discover the perfect tool that balances performance and value.

So, let’s get started and find the ideal vise for your next project!

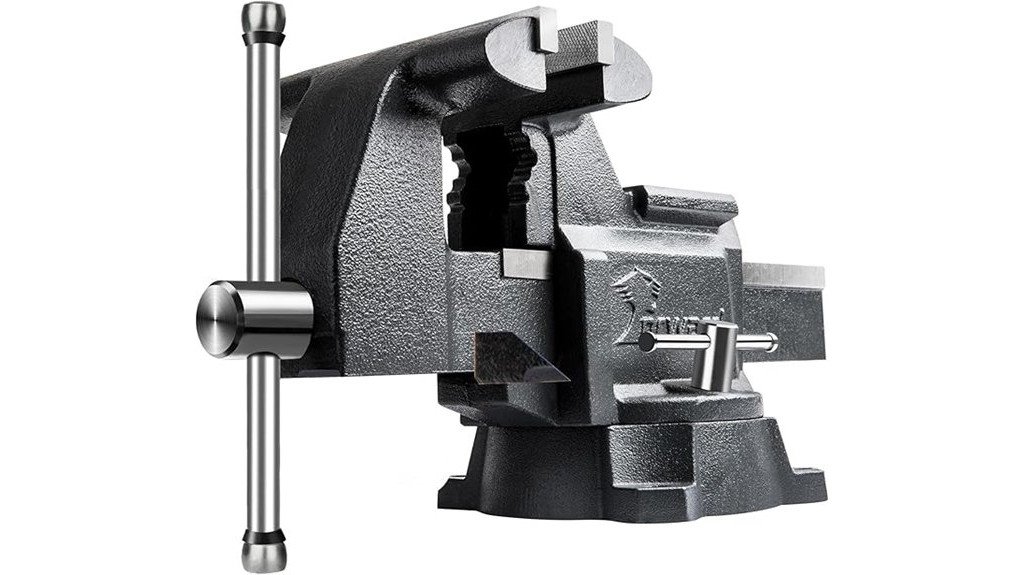

Forward CR40A 4.5 Inch Bench Vise Heavy Duty Vice with Anvil and 210° Swivel Base

If you’re a hobbyist or professional woodworker who needs a vise that combines strength with flexibility, the Forward CR40A 4.5-inch bench vise is a solid pick: its 6600 lb clamping force and ductile iron construction give you heavy-duty holding power, while the 210° swivel base and built-in pipe jaws let you lock workpieces at awkward angles and handle round stock without swapping tools. You’ll appreciate the 4.5-inch serrated replaceable jaws plus pipe grips, a 5-inch opening and 2.6-inch throat depth for varied tasks, and the large anvil for light hammering. It’s sturdy, versatile, and well-rated, though rust and lubrication need attention.

Best For: Hobbyist and professional woodworkers or metalworkers who need a sturdy, versatile bench vise with high clamping force and a swivel base for angled or pipe work.

Pros:

- Heavy-duty 6600 lb (30 kN) clamping force with durable ductile iron construction for reliable holding power.

- 210° swivel base, built-in pipe jaws, and replaceable serrated jaws provide versatility for angled work and round stock.

- Large anvil and 5-inch jaw opening with 4.5-inch jaw width accommodate a wide range of tasks.

Cons:

- Prone to surface rust if not regularly maintained or properly protected.

- Requires periodic lubrication to keep smooth sliding and lockdown performance.

- At ~19 lb, heavier than some hobby vises, which may be less convenient for lighter, portable setups.

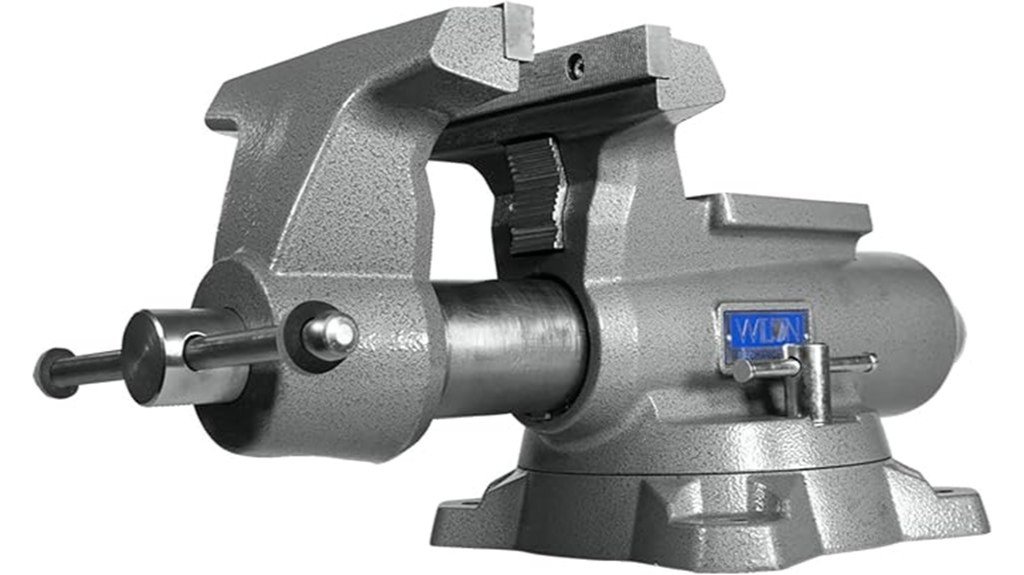

Wilton Mechanics Pro Bench Vise (Model 880M), 8″ Jaw Width, 8.5″ Jaw Opening

For woodworkers and metalworkers who need a heavy-duty, reliable hold, the Wilton Mechanics Pro 880M stands out as a workhorse thanks to its 8″ jaw width, 8.5″ maximum opening, and 60,000 psi ductile iron construction—features that deliver both strength and precision for demanding tasks. You’ll appreciate the precision-machined slide bar that eliminates front-jaw movement and the enclosed spindle that keeps lubricants in while blocking contaminants. A needle roller thrust bearing boosts clamping force with less effort, the 360° swivel base locks securely, and the large anvil handles striking work. Note some shipping damage reports, but a lifetime warranty eases concerns.

Best For: Woodworkers and metalworkers who need a heavy-duty, reliable bench vise for demanding clamping, striking, and general fabrication tasks.

Pros:

- Durable 60,000 psi ductile iron and alloy steel construction with precision-machined slide bar for minimal front-jaw movement.

- Needle roller thrust bearing and enclosed spindle provide higher clamping force with less effort and better lubricant/contaminant protection.

- 360° swivel base with double lockdowns and a large anvil surface add versatility for various shop tasks.

Cons:

- Reported shipping and packaging issues have led to damaged boxes and occasional bent handles on delivery.

- At 83.1 pounds and large dimensions, it’s heavy and may be difficult to position or mount for some users.

- Initial handling or setup can be awkward for users unfamiliar with heavy bench vises.

WORKPRO Dual Jaws Table Vise (2.5″ & 1.5″), 360° Swivel Clamp-On Mini Bench Vise

The WORKPRO Dual Jaws Table Vise is a smart choice if you need a compact, multi-purpose clamp that handles a range of small projects, from woodworking and metalworking to golf club regripping. You get dual jaws—2.5″ serrated and 1.5″ smooth—so you can grip pipes, tubes, and delicate pieces without switching tools. Built from ductile iron with hardened carbon steel jaws and a galvanized handle, it withstands heavy use and delivers up to 660 lbs of clamping force. The 360° swivel and clamp-on or bolt-down mounting add flexibility, though its small size may limit some bench fits.

Best For: compact hobbyists and DIYers who need a versatile, clamp-on mini bench vise for woodworking, metalworking, and small projects (including golf club regripping).

Pros:

- Dual jaws (2.5″ serrated and 1.5″ smooth) for gripping a wide range of materials without switching tools.

- Durable construction (ductile iron body, hardened carbon steel jaws, galvanized handle) with up to 660 lbs clamping force.

- 360° swivel and clamp-on or bolt-down mounting provide flexible positioning and easy installation.

Cons:

- Compact size may be too small for larger workpieces or heavy-duty bench use.

- Clamp-on width/shape may not fit all workbench edges.

- 1/4-20 bolts for permanent mounting are not included.

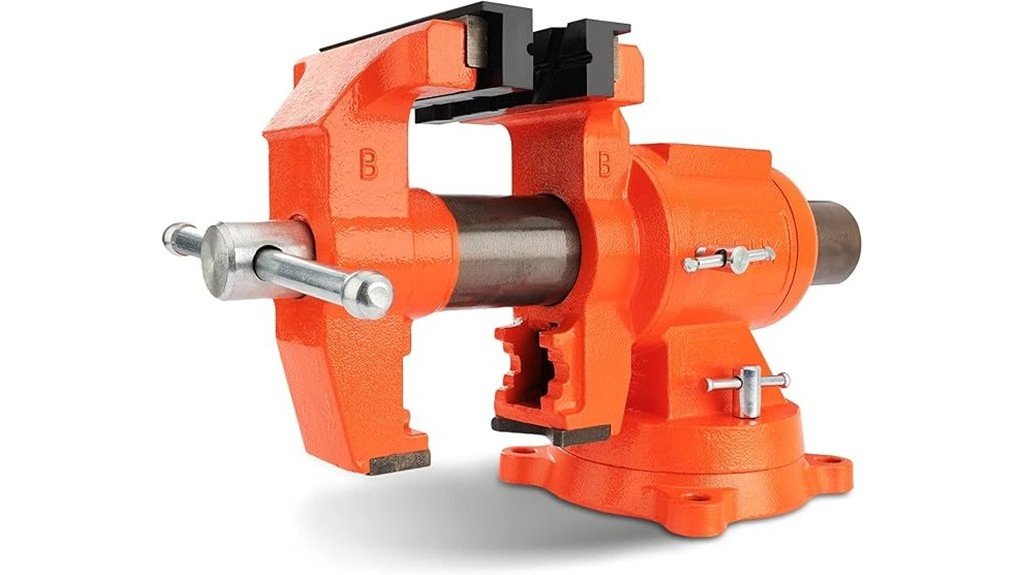

PONY 5-inch Heavy Duty Bench Vise with 360-Degree Swivel Base and Anvil

Woodworkers who need a versatile, budget-friendly vise that’ll handle light- to medium-duty shop tasks will appreciate the PONY 5-inch Heavy Duty Bench Vise, which pairs a 360-degree swivel base with a hardened anvil surface for multi-angle clamping and shaping. You get a 5-inch jaw width, 5-inch opening and 2-5/8-inch throat depth in a 25.6-pound cast iron body that stands up to grinding, sawing, sanding, and gluing. Replaceable hardened steel serrated jaws and permanent pipe jaws increase versatility, while safety features prevent main jaw dislodging. Reviewers praise its holding power and value; limited fit-and-finish suits hobbyists.

Best For: Woodworkers and hobbyists who need a budget-friendly, versatile bench vise for light- to medium-duty shop tasks like grinding, sawing, sanding, gluing, and occasional pipe work.

Pros:

- 360-degree swivel base and hardened anvil offer multi-angle clamping and shaping flexibility.

- Replaceable hardened steel serrated jaws and permanent pipe jaws increase versatility and holding power.

- Solid cast-iron construction with safety features provides good value and reliable performance for the price.

Cons:

- Fit and finish reflect its budget positioning and may not meet professional-grade expectations.

- 5-inch size and 25.6 lb weight limit heavy industrial or continuous heavy-duty use.

- Throat depth (2-5/8″) and jaw opening (5″) can restrict clamping of larger workpieces.

VEVOR 6-Inch Bench Vise with 360° Swivel Base and Anvil (Heavy Duty)

If you want a heavy-duty vise that handles both flat stock and pipe work without fuss, the VEVOR 6-inch bench vise is a compelling choice, thanks to its 360° swivel base and multi-jaw design. You’ll get 6-inch jaws, a 5.9-inch opening, and a 3.5-inch throat depth, built from 60,000 PSI ductile iron with powder coating for rust resistance. It delivers up to 20 kN clamping force, includes replaceable carbon-steel serrated jaw plates, a 2.9 x 3-inch anvil, and magnetic jaw pads. Installation is straightforward, though you may need longer mounting bolts for thick benches.

Best For: DIYers and small workshop users who need a versatile, heavy‑duty bench vise for both flat stock and pipe work with a 360° swivel and an integrated anvil.

Pros:

- Robust construction (60,000 PSI ductile iron, powder coated) and up to 20 kN clamping force for heavy use.

- 360° swivel base, multi‑jaw design, and replaceable serrated carbon‑steel jaw plates for versatility (flat and pipe clamping).

- Includes a 2.9 x 3 in anvil and magnetic jaw pads; highly rated for value and ease of installation.

Cons:

- Mounting bolts included may be too short for thicker workbenches, requiring additional purchases.

- Some users report occasional minor jaw misalignment out of the box.

- At 25 lbs and substantial size, it may be bulky for very small or portable setups.

Factors to Consider When Choosing Woodworking Bench Vises

When choosing a bench vise, you’ll want to compare jaw type and material—soft faced for delicate work or hardened steel for tougher clamping—and match that to the clamping force you actually need for your projects. Consider throat depth carefully, since a deeper throat lets you hold larger workpieces, and decide whether a swivel base will add the flexibility your bench requires. Also look at the anvil size and how you’ll use it for shaping or striking, because a larger, well-finished anvil can make everyday tasks much easier.

Jaw Type and Material

Because the jaws are the primary point of contact between your workpiece and the vise, their type and material determine how securely and safely you can clamp different projects. Choose serrated jaws when you need enhanced grip on flat, hard surfaces; pick smooth jaws for softer woods or finished pieces to avoid marring. Materials matter: cast iron gives reliable strength, while ductile iron offers higher tensile strength—often around 60,000 PSI—making it better for heavy-duty tasks. Look for replaceable jaw inserts so you can swap worn faces or tailor surfaces for specific jobs, extending the vise’s life. Also consider jaw width and maximum opening capacity, since wider jaws and larger openings let you handle bulkier workpieces with confidence and flexibility.

Clamping Force Needed

Jaw material and design affect grip, but you also need to match the vise’s clamping force to the work you’ll be doing; stronger clamping force gives you confident, slip-free holding for larger or tougher pieces, while lower force lets you handle delicate or finished surfaces without crushing them. Start by evaluating your projects: routine woodworking usually performs well with vises rated around 5,000–6,000 lbs, which offer secure holding for bigger boards and tougher joins. If you mostly work on small, delicate parts, a lower-force vise near 660 lbs provides precise control without bruising the wood. Remember that jaw design and the clamped material influence effective force, so pick a vise whose rated capacity aligns with both the size and fragility of your work to guarantee consistent, damage-free clamping.

Throat Depth Importance

Although you may not notice it at first, throat depth plays a critical role in how much and what kind of material your vise can hold, so you should give it careful consideration when choosing a bench vise. Throat depth is the vertical distance from the vise base to the bottom of the jaws, and it directly limits the maximum size of workpieces you can clamp securely. A deeper throat increases versatility, letting you handle thicker or bulkier stock without resorting to awkward setups. For most woodworking tasks, aim for at least 2.5 to 3 inches of throat depth to cover common boards and assemblies. Adequate depth also improves leverage and stability, reducing jaw bending or misalignment when you apply force. Match throat depth to the typical material sizes you work with.

Swivel Base Options

Once you’ve settled on a throat depth that suits the stock you work with, consider how a swivel base can add reach and convenience without forcing you to reposition the entire workpiece. A swivel base lets the vise rotate — sometimes up to 360 degrees — so you can access different angles quickly, which boosts efficiency on complex assemblies or pipe fitting. Some models, like the Forward CR40A, use a 210-degree lockdown that balances range with secure positioning. Be sure the base locks solidly to prevent unwanted movement when you apply pressure, maintaining precise holds during cutting or shaping. Also look for a larger base surface for extra stability with heavy pieces, since it helps prevent tipping and keeps work safe.

Anvil Size & Use

Think of the anvil on a bench vise as a small, versatile work platform: its size and finish affect how and what you can do when you need to hammer, shape, or bend material. You’ll find anvil surfaces typically range from about 2 to 5 inches; larger surfaces give you more room for bending, forming, and striking, and they’re especially helpful if you ever tack on light metalwork tasks. A ground and polished anvil delivers a flat, consistent surface for precision jobs, so you can trust repeatable results. Consider whether the vise offers permanent pipe jaws or replaceable jaws: permanent jaws add rigidity, while replaceable ones let you adapt to different shapes and protect the anvil. Match anvil size to the kinds of tasks you expect to perform.

Mounting and Fit

Because a vise is only as useful as the way it’s attached, you’ll want to start by matching the mounting style and size to your bench and projects so the tool stays rock-solid when you need it most. Decide between clamp-on and bolt-down models: clamp-on gives portability but can shift under heavy load, while bolt-down offers permanence and maximum stability. Measure overall dimensions and jaw width so the vise fits your bench and handles stock sizes you commonly use. Check throat depth to confirm you can clamp where you need to, and prefer an adjustable or swivel base for easier positioning and multi-angle work. Finally, verify rated clamping force to guarantee the vise holds securely without slipping during demanding tasks.

FAQ

Can a Bench Vise Damage Delicate Wood Surfaces?

FAQs on Using a Bench Vise with Delicate Wood Surfaces

1. Can a bench vise damage delicate wood surfaces?

Yes, clamping directly onto delicate wood can cause damage such as marring and indentations.

2. What should I use to protect delicate wood when using a bench vise?

Use soft jaw covers, leather strips, or sacrificial wood cheeks to distribute pressure and protect the surface.

3. How should I tighten the vise to prevent damage?

Tighten the vise gradually and check the alignment frequently to avoid excessive pressure on the wood.

4. Are there alternatives to using a bench vise for fragile pieces?

Yes, consider using padded clamps or a bench hook, which can offer a gentler grip on delicate materials.

5. What happens if I over-torque the vise?

Over-torquing can lead to significant damage, including crushed fibers and a compromised finish on the wood.

6. How can I ensure I don’t compromise the wood’s appearance?

Controlled clamping is key; use protective measures and avoid applying too much force during the clamping process.

7. Can I use my bench vise for all types of wood?

Not all woods are suitable for direct clamping; softer or more delicate woods require added protection to prevent damage.

8. What types of jaw covers are best for delicate wood?

Soft materials like rubber or felt are effective as they cushion the wood and help prevent marks.

9. Is it necessary to check alignment while clamping?

Yes, regularly checking alignment helps maintain proper pressure and prevents unintentional damage.

10. How can I maintain the integrity of the wood grain while using a vise?

Using protective covers and controlled clamping will help preserve the wood grain and finish throughout your project.

Are These Vises Suitable for Metalworking Tasks?

1. Can woodworking vises be used for metalworking tasks?

Yes, woodworking vises can handle light metalwork tasks, but they are not suitable for heavy-duty metal shaping.

2. What types of metalworking tasks can woodworking vises handle?

Woodworking vises are adequate for filing, sanding, and light drilling when enhanced with hardened steel jaws or soft-padded covers.

3. What vise is recommended for heavy metalworking tasks?

For heavy cutting, forging, or tapping, it is best to use a machinist’s or metalworking vise designed for higher jaw pressure and heat-treated components.

4. How can I enhance the performance of a woodworking vise for metalwork?

Adding hardened steel jaws or soft-padded covers can improve clamping for light metalwork tasks.

5. What should I check before using a woodworking vise for metalworking?

Inspect the screw strength and mounting of the vise to ensure it can handle the intended metalworking tasks without damage.

6. Are there any limitations when using woodworking vises for metalwork?

Yes, avoid stressing wooden jaws beyond their design limits, as they are not built for heavy metalworking tasks.

7. Is clamping pressure important for metalworking vises?

Yes, higher jaw pressure is essential for effectively securing metal pieces during heavy-duty tasks.

8. What materials are best for metalworking vise jaws?

Heat-treated components and hardened steel jaws are ideal for metalworking vises to ensure durability and stability.

9. Can I use a woodworking vise for welding tasks?

No, woodworking vises are not suitable for welding tasks due to their material limitations and potential damage from heat.

10. What is the main difference between woodworking and metalworking vises?

Metalworking vises are specifically designed for higher stress and durability, while woodworking vises are tailored for lighter applications.

How Do I Lubricate and Maintain the Vise Mechanism?

FAQs on Lubricating and Maintaining the Vise Mechanism

1. How do I clean the vise before lubrication?

Clean the jaws, screw, and guide rods using a brush and solvent. Make sure to dry all parts thoroughly before applying lubricant.

2. What type of lubricant should I use on the vise?

A light coat of machine oil or white lithium grease is recommended for lubricating the screw and sliding surfaces of the vise.

3. How do I distribute the lubricant effectively?

After applying the lubricant, work the screw back and forth to ensure even distribution across the surfaces.

4. What should I inspect during maintenance?

Regularly check for wear on the vise components, tighten any loose fasteners, and look for damaged pads that may need replacement.

5. How do I remove excess lubricant after maintenance?

Use a clean cloth to wipe away any excess oil after lubricating the vise to prevent debris accumulation.

6. How often should I lubricate the vise?

It is advisable to lubricate the vise every few months or after heavy use to maintain its performance.

7. Can I use any type of grease for lubrication?

It’s best to use machine oil or white lithium grease, as these types are designed for metal-to-metal contact and provide optimal protection.

8. What should I do if the vise mechanism feels stiff after lubrication?

If the vise feels stiff, ensure that it has been properly cleaned and lubricated, and check for any debris or damage that might be causing the stiffness.

9. Is it necessary to store the vise in a dry place?

Yes, storing the vise dry helps prevent rust and corrosion, ensuring longevity and optimal functionality.

10. What are the signs that my vise needs maintenance?

Signs include difficulty in opening or closing the jaws, visible wear on components, or loose fasteners that can affect operation.

Can I Mount a Vise to MDF or Particleboard Benches?

FAQ 1: Can I mount a heavy vise directly to an MDF bench?

No, it’s not advisable to mount a heavy vise directly to MDF. The material can crush and strip under concentrated loads.

FAQ 2: What happens if I mount a vise directly to particleboard?

Mounting a vise directly to particleboard can lead to loosening bolts over time due to the material’s inability to handle concentrated loads.

FAQ 3: How can I reinforce MDF or particleboard for mounting a vise?

To reinforce the surface, attach a hardwood or plywood mounting block that is glued and screwed to the bench.

FAQ 4: What should I use to distribute the load of the vise?

It’s recommended to use backing plates or a steel mounting plate to help spread the load more evenly.

FAQ 5: What type of bolts should I use for mounting a vise?

Use proper carriage bolts along with washers and nuts to ensure a secure mount.

FAQ 6: How often should I check the tightness of the vise bolts?

It’s important to periodically check the tightness of the bolts to prevent any potential failure.

FAQ 7: Can I use just screws to mount the vise?

Screws alone are not sufficient; you should use bolts with a secure backing to ensure stability.

FAQ 8: Is it necessary to glue the mounting block?

Yes, gluing the mounting block provides additional stability and helps prevent movement over time.

FAQ 9: Will mounting a vise to MDF or particleboard ever be safe?

Not without proper reinforcement; without it, the risk of failure increases significantly.

FAQ 10: What is the best type of mounting block for this purpose?

A hardwood or plywood block is ideal for mounting a vise, as it can handle the stress better than MDF or particleboard alone.

Are Replacement Jaws or Parts Readily Available?

FAQs on Replacement Jaws and Parts Availability

1. Are replacement jaws for vises easy to find?

Yes, replacement jaws are generally easy to locate, especially for popular vise brands and models.

2. What types of jaws can I find for replacement?

You can find options such as steel, hardened, and soft jaws available for replacement.

3. Where can I purchase replacement parts for my vise?

Replacement parts like screws, slides, and handle assemblies can be purchased from manufacturers or aftermarket suppliers.

4. How do I ensure compatibility when buying replacement jaws?

Check the model numbers and jaw width of your vise to ensure a proper fit for the replacement jaws.

5. Are there kits available for easier installation?

Yes, ordered kits are often available, making the installation process simpler.

6. What if I have a lesser-known vise brand?

For lesser-known brands, you may need to look into custom machining or third-party parts.

7. Is it common to find aftermarket suppliers for vise parts?

Yes, aftermarket suppliers frequently offer a variety of replacement parts for different vise models.

8. Can I replace just one jaw, or do I need to replace both?

You can replace just one jaw, but it’s often recommended to replace both for even wear and better functionality.

9. How do I know if my vise is a common model?

Research your vise’s brand and model online to see if it’s listed among commonly found vises for which parts are readily available.

10. What should I do if I can’t find parts for my vise model?

If parts are unavailable, consider reaching out to custom machining services or forums for advice on sourcing third-party options.

11. Are replacement parts usually durable?

Replacement parts, especially those made from steel or hardened materials, are typically designed for durability and longevity.

Final Thoughts

You’ll want a vise that matches the work you do: choose the Forward CR40A or PONY for versatile swivel and anvil work, the Wilton Mechanics Pro for heavy-duty precision, the VEVOR for rust-resistant durability, and the WORKPRO mini vise for detailed clamp-on tasks. Consider jaw material and throat depth, plus smooth versus serrated faces for finish work. Pick the model that balances strength, versatility, and jaw options to suit your projects and budget.