Are you a beginner woodworker looking to elevate your projects with a reliable benchtop planer? Selecting the right tool can greatly enhance your woodworking experience by saving you time and minimizing frustration.

This guide is designed specifically for novice woodworkers who want an easy-to-use, accurate, and budget-friendly option that meets their needs.

In this roundup, we’ve curated five top-notch benchtop planers that strike a perfect balance between power, cut quality, and snipe reduction.

Whether you’re working on small home projects or setting up a modest workshop, these models provide the essential features that hobbyists require. From innovative spiral cutterheads to compact, portable designs, each option has its unique strengths to help you achieve smooth, finished surfaces.

No matter your budget, our selection offers reliable choices that prioritize user-friendliness without sacrificing performance.

Ready to find the perfect benchtop planer to kickstart your woodworking journey? Keep reading to explore our top picks!

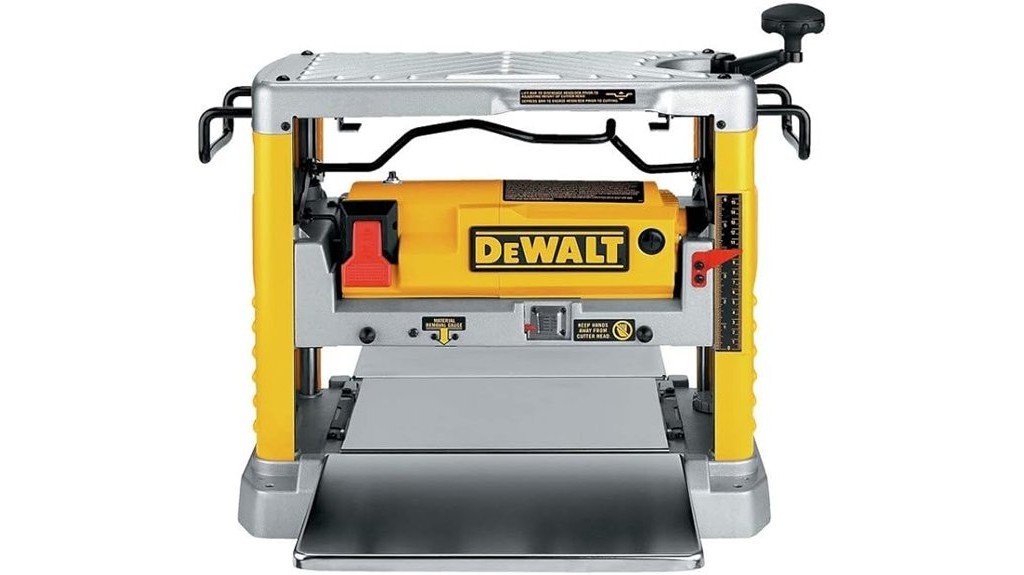

DEWALT Benchtop Planer 12-1/2-Inch (DW734)

If you’re a beginner woodworker who wants reliable, workshop-ready performance without a steep learning curve, the DEWALT DW734 is a strong choice—think of it as a workhorse that’s easy to tame. You’ll get a 15‑amp motor with a 12-1/2-inch cutting width and three-knife cutter head delivering 96 cuts per inch for fine finishes. The extra-long 33-1/2-inch tables and four-column carriage lock reduce snipe, and disposable reversible knives last longer. Users praise quick setup, good dust collection, and consistent hardwood performance, though the height gauge and nonfolding trays could be more precise or space-friendly. A solid, dependable option.

Best For: Beginner to intermediate woodworkers who want a reliable, workshop-ready benchtop planer that delivers smooth finishes on hardwoods without a steep learning curve.

Pros:

- Powerful 15-Amp motor with a 12-1/2″ cutting width and three-knife cutter head (96 cuts per inch) for fine, consistent finishes.

- Extra-long 33-1/2″ infeed/outfeed tables and four-column carriage lock reduce snipe and support longer boards.

- Disposable reversible knives for easier maintenance and longer life; quick setup and effective dust collection with a shop vac.

Cons:

- Height gauge and fixed stops can lack precision for users needing exact thickness control.

- Infeed and outfeed trays do not fold, taking up more workshop space.

- Emergency shut-off switch location may be inconvenient during operation.

Cutech 13-Inch Benchtop Planer with 26 Tungsten Carbide Inserts

The Cutech 13-inch benchtop planer stands out for beginners who want professional-feeling results without a workshop-sized machine, thanks largely to its 26 tungsten carbide inserts arranged in a spiral cutterhead that delivers consistently smooth surfaces and reduced noise. You’ll appreciate the 2-speed feed for tackling hardwoods, an 8-position depth stop for repeatable thicknessing, and a handy depth-of-cut indicator. The snipe minimizer with four lead screws reduces end defects, while the flip dust hood helps chip removal. At about 76 pounds and easy assembly, it’s versatile for boards, cutting boards, and flooring, though check returns if delivery has issues.

Best For: Beginners and hobbyist woodworkers who want near-professional, smooth finishing from a compact benchtop planer without needing a full-size shop.

Pros:

- Spiral cutterhead with 26 tungsten carbide inserts delivers very smooth, quiet cuts and reduces sanding.

- Integrated snipe minimizer and 8-position depth stop provide consistent thicknessing and minimal end defects.

- Two-speed feed and flip dust hood increase versatility for hardwoods and improve chip extraction.

Cons:

- Some users report quality-control issues on delivery (broken parts or debris), so inspect upon arrival and be prepared to return if needed.

- At about 76 pounds, it’s portable for a benchtop unit but may be heavy for occasional transport or small workspaces.

- Replacement carbide inserts and maintenance can be more costly than standard knives.

VEVOR 13-Inch Two-Blade Benchtop Thickness Planer (1800W, 23500 RPM)

Woodworkers just starting out who need a reliable, heavy-duty benchtop planer will appreciate the VEVOR 13-inch two-blade model for its combination of power and precision: its 1800W motor and high-speed cutterhead deliver up to 16,000 cuts per minute, while the 13-inch cutting width and 1/8-inch maximum depth let you tame wider boards with accurate, repeatable passes. You’ll value the dual-roller feeding system for reduced vibration and better alignment, and the two HSS blades for smooth edges. At about 58 pounds, the aluminum table offers stability for long or warped stock; dust ports accept 2″ or 4″ hoses.

Best For: Woodworkers starting out who need a reliable, heavy-duty benchtop planer that combines strong motor power with precise, repeatable cuts for wider boards.

Pros:

- 1800W motor and high-speed cutterhead (up to 16,000 CPM) for efficient hardwood planing.

- 13-inch cutting width and 1/8-inch maximum depth allow accurate passes on wider stock.

- Dual-roller feed and two HSS blades reduce vibration, improve alignment, and produce smooth edges.

Cons:

- At about 58 pounds, it’s less portable than lighter benchtop models.

- Aluminum construction may be less durable than cast-iron top-end planers for heavy industrial use.

- Warranty details require checking the product link, adding a step before purchase.

CRAFTSMAN 15 Amp Benchtop Planer (CMEW320)

For beginner woodworkers who need a portable, reliable machine for dimensioning lumber and planing glued-up boards, the CRAFTSMAN 15 Amp Benchtop Planer (CMEW320) stands out for its combination of power and user-friendly features. You’ll get a 15‑amp motor and a two‑knife solid steel cutter head running at 8,000 RPM, delivering 16,000 cuts per minute for smooth results on soft and hardwoods. The reversible high‑carbon knives and ball‑bearing mounting promote longevity and smooth operation, while a poly‑V drive boosts stock removal. It’s portable, easy to set up, includes dust collection, and comes with a three‑year warranty.

Best For: Beginner to intermediate woodworkers who need a portable, reliable benchtop planer for dimensioning lumber and planing glued-up boards.

Pros:

- 15‑amp motor with a two‑knife solid steel cutter head (8,000 RPM / 16,000 cuts per minute) delivers smooth results on soft and hardwoods.

- Reversible high‑carbon knives, ball‑bearing cutter head, and poly‑V drive provide durability, smooth operation, and strong stock removal.

- Portable and easy to set up (typically <15 minutes) with dust-collection port and a 3-year limited warranty.

Cons:

- Tendency to produce snipe at board ends unless careful feed technique or light passes are used.

- Knife wear can occur with hardwoods, so extra blades may be needed and maintenance is required.

- At 61 lbs and benchtop size, it may be less stable or capable than larger floor-standing planers for heavy production work.

WEN PL1252 15-Amp 12.5-Inch Two-Blade Benchtop Thickness Planer , Black

If you’re just getting into woodworking and want a reliable, compact thickness planer that won’t overwhelm your bench space, the WEN PL1252 is a strong candidate thanks to its 15-amp motor and 12.5-inch cutting width. You’ll appreciate a cast-iron body, two reversible SK5 blades, and a 20,000 RPM cutterhead that delivers 20,000 cuts per minute at a 26 ft/min feed rate. It planes boards up to 6 inches thick, adjusts depth to 1/8 inch, and includes return rollers, adjustable tables, and a 2-inch dust port. Users praise finish quality; expect moderate noise and standard dust collection.

Best For: Hobbyist and entry-level woodworkers who need a compact, affordable benchtop planer for smoothing and sizing boards up to 12.5″ wide without taking up much bench space.

Pros:

- Cast-iron body and 15A motor with two reversible SK5 blades deliver smooth finishes and reliable cutting performance.

- Compact footprint (20 x 12.5 in) and onboard handles make it easy to move and fit into small workshops.

- Adjustable infeed/outfeed tables, return rollers, and a 2-inch dust port increase usability and help reduce snipe and mess.

Cons:

- Dust collection via the 2-inch port and included system can be only moderately effective, so a shop vacuum or better dust setup may be needed.

- Noticeable noise during operation typical of powerful benchtop planers.

- Maximum cutting depth limited to 1/8 inch per pass, which may require multiple passes for large stock removal.

Factors to Consider When Choosing Bench Planers for Beginner Woodworkers

When you’re choosing a benchtop planer, pay close attention to cutting capacity limits and motor power so the machine can handle the board sizes and hardwoods you’ll work with. You’ll also want ease of setup and blade type options that match your skill level and maintenance willingness, plus features that reduce snipe to keep your ends clean. Considering these factors together will help you pick a planer that’s powerful enough, simple to use, and produces professional results.

Cutting Capacity Limits

Anyone stepping into woodworking soon notices that a benchtop planer’s cutting capacity — its maximum width and the depth it can remove in a single pass — plays a central role in what projects you can realistically tackle. Cutting capacity usually falls around 12–13 inches wide and up to 0.25 inches deep per pass, so pick a planer that matches the board sizes you plan to use. Wider cutters let you handle larger boards and increase project versatility, while adjustable cutting depth, typically between 1/8 and 1/4 inch per pass, determines how quickly you reach desired thicknesses. Check the maximum board thickness rating, often 6–8 inches, and remember denser hardwoods demand sturdier blade setups and higher RPMs for smoother, efficient cuts.

Motor Power Requirements

Choosing the right motor power for a benchtop planer matters more than many beginners expect, because it directly affects what woods you can work with and how quickly you’ll reach a smooth, accurate thickness. You’ll usually see power listed in amperage — 15 Amps is common for entry-level machines and handles both softwoods and many hardwoods reliably. Pay attention to RPM and CPM too: motors spinning between about 10,000–20,000 RPM and producing up to 26,000 cuts per minute deliver smoother finishes and faster stock removal. Higher-wattage motors, for example around 1800W, tolerate deeper cuts and tougher species better. Finally, choose a motor that holds consistent power under load; if it bogs down, surface quality and accuracy suffer, so prioritize steady performance.

Ease of Setup

Motor power helps determine what you can plane and how smoothly the tool runs, but setup often dictates how quickly you’ll get from unboxing to a usable machine. You’ll appreciate models that assemble in under 20 minutes, since faster setup gets you working and reduces frustration. Check for clear, intuitive manuals and step‑by‑step guides that match your skill level; well‑illustrated instructions cut errors. A straightforward design with few components makes assembly more manageable, and quick‑change knife systems let you replace blades without special tools or experience. Also look for predrilled base holes so you can secure the planer to a bench quickly, improving stability and safety. Prioritize ease of setup to spend more time learning technique and less time wrestling with hardware.

Blade Type Options

While blade choice might seem like a small detail, it has a major impact on the finish, noise, maintenance, and long‑term cost of a benchtop planer, so you’ll want to understand the differences before you buy. You’ll typically see straight knives or spiral cutterheads: straight knives are common, usually high‑carbon steel, reversible for longer life and lower cost per use, and relatively easy to replace. Spiral cutterheads use many tungsten carbide inserts arranged staggered for quieter, smoother passes and less frequent sharpening, ideal for detailed work. Also note knife count: three‑knife systems usually cut faster and leave a finer finish than two‑knife setups. Pick a model with straightforward replacement and adjustment features to save time and frustration as you learn.

Snipe Reduction Features

Because end‑grain can lift or shift slightly as a board enters and exits the cutterhead, snipe is one of the most common frustrations new users face, but several built‑in features can greatly reduce it and improve your results. Look for four‑column carriage locks; they stabilize the workpiece and minimize end snipe by holding the table alignment steady. Some models use integrated snipe‑minimizer systems with multiple lead screws to maintain perfect tracking without extra clamps. Adjustable infeed and outfeed tables are also valuable, since better support as the board moves through the cutterhead lessens movement at the ends. A reliable depth stop keeps the cut depth uniform, which helps prevent sudden material shifts. Finally, take lighter passes and feed the board straight; user technique complements built‑in features for best results.

Dust Collection Compatibility

Good dust collection can make a big difference to your workshop comfort and health, so when you’re choosing a benchtop planer you should look closely at how well it mates with your vacuum or dust system. Effective collection reduces airborne fine dust and keeps your workspace cleaner, which helps protect your lungs and improves visibility while you work. Check whether the planer has a dust port sized for common shop vac hoses, and prefer models that accept 2-inch or 4-inch connections for better airflow. Some planers include integrated dust hoods or improved chip ejection paths that cut clogging and make the vacuum more effective. Choosing a planer with proven dust-management features makes cleanup faster and supports more accurate, enjoyable woodworking sessions.

Safety and Ergonomics

When you’re choosing a benchtop planer, prioritize safety and ergonomics alongside performance, because the right features protect you and make the tool easier to use for longer sessions. Look for emergency shut-off switches and reliable blade guards to minimize accident risk, and guarantee controls are intuitive so you can react quickly. Comfortable handles and an adjustable table reduce strain and improve control during repetitive passes, helping you maintain accuracy without tiring. A well-placed dust port that ties into your collector or shop vac keeps chips and fine dust from filling the air, lowering inhalation hazards. Before you start, secure the planer to a stable surface to prevent movement; remember that lighter models can be easier to move but might feel less stable during heavy cuts.

Size and Portability

Size and portability matter a lot when you’re picking a benchtop planer, since they determine what you can process, where you can work, and how easy it is to move and store the tool. Check cutting width first: most models sit around 12.5 to 13 inches, which limits board size and guides what projects you can tackle. Weight matters too—many planers weigh 57 to 80 pounds—so if you’ll carry it between job sites or store it frequently, choose a lighter unit. Compact footprints help in tight shops, and features like onboard handles or pre-drilled mounting holes make transport and secure placement simpler. Finally, longer infeed and outfeed tables support bigger pieces and reduce snipe, improving stability and finish for beginners.

FAQ

Can a Benchtop Planer Be Used on Reclaimed or Knotty Wood Safely?

1. Can I use a benchtop planer on reclaimed wood?

Yes, a benchtop planer can be used on reclaimed wood. However, it’s important to inspect for and remove any nails or metal before planing.

2. Is it safe to plane knotty wood?

Yes, knotty wood can be planed, but you should mark dense knots to avoid potential issues. Proceed carefully to minimize damage to the blades.

3. What precautions should I take before planing reclaimed wood?

Inspect the wood thoroughly for hidden nails or metal that could damage the planer. Ensure all such debris is removed before proceeding.

4. How should I handle dense knots while planing?

Mark dense knots on the wood to monitor them during planing. Take light passes to reduce the risk of tear-out around these areas.

5. What settings should I use for planing knotty wood?

Use sharp blades and adjust to slower feed rates for better results. This can help reduce tear-out and improve overall finish quality.

6. What is the best way to prevent snipe when planing long boards?

Support long boards adequately as they enter and exit the planer to prevent snipe. Properly supporting the wood can help maintain even thickness.

7. What should I expect when planing reclaimed or knotty wood?

Expect more tear-out and occasional chip-out compared to smooth, uniform wood. These imperfections are more common with reclaimed or knotty materials.

8. How can I fix imperfections after planing?

After planing, you can sand the surface or fill any imperfections with wood filler to achieve a smoother finish. This step is crucial for enhancing the final appearance.

9. Are there any specific blade requirements for planing reclaimed wood?

It’s best to use sharp blades when planing reclaimed wood to minimize tear-out. Dull blades can exacerbate issues with rough surfaces.

10. How can I achieve a smoother finish on reclaimed wood?

After planing, sand the wood to remove any rough spots or tear-out. This will help create a smoother, more polished final result.

How Do I Transport a Benchtop Planer Without Damaging It?

FAQ: How to Transport a Benchtop Planer

1. What precautions should I take before moving my benchtop planer?

Ensure you secure and pad the planer, drain any fluids, and lock any moving parts to prevent damage during transportation.

2. How should I wrap my planer for transport?

Wrap the planer in moving blankets and foam to provide adequate cushioning, then use straps to secure it in place to prevent shifting.

3. Is it better to move the planer with two people?

Yes, carrying the planer with two people is recommended, especially for heavier models, to avoid strain and ensure stability.

4. Can I use a dolly for transporting my benchtop planer?

Absolutely, using a dolly is a great option for heavy models, as it allows for easier movement and reduces the risk of injury.

5. Should the planer be laid down during transport?

No, always keep the planer upright during transport to protect its bearings and blades from damage.

6. What should I do if the planer has fragile parts?

Label the fragile sides clearly to alert anyone handling it to take extra care and avoid any unnecessary pressure.

7. Can I stack other items on top of the planer during transport?

No, avoid stacking heavy items on top of the planer to prevent crushing or damaging its components.

8. What should I check after reaching my destination?

Once you arrive, check for blade alignment and ensure all fasteners are secure to maintain the tool’s performance.

9. How do I ensure the planer doesn’t get scratched or scuffed?

In addition to wrapping it with blankets, be cautious of the surfaces it comes in contact with during transport to minimize the risk of scratches.

10. What if I’m transporting the planer over a long distance?

For long-distance transport, make sure it’s securely fastened and consider additional padding to protect it from bumps and jostling.

11. Is there anything else to keep in mind while transporting my benchtop planer?

Always handle the planer with care, and make a plan for loading and unloading that minimizes risks to both the tool and the people involved.

Can I Plane End Grain Successfully With These Machines?

1. Can I use a benchtop planer for end grain?

Yes, a benchtop planer can be used for end grain, but results may vary depending on your technique.

2. What techniques should I use when planing end grain?

Use short passes, a minimal depth of cut, and ensure your knives are sharp to minimize tearout.

3. How can I reduce tearout when planing end grain?

Backing the board with sacrificial stock can help support the fibers and reduce tearout during planing.

4. What is the best feed rate for planing end grain?

Feed slowly and maintain consistent pressure to prevent snipe and achieve a smoother finish.

5. Is it necessary to sand after planing end grain?

For the cleanest finish, sanding after planing is recommended to smooth any remaining imperfections.

6. Can a jointer be used on end grain?

A jointer can be used for end grain, but it may not provide the best results compared to other methods.

7. What alternative tools can I use for precise trimming of end grain?

A router plane is an excellent choice for precise, tearout-free trimming of end grain.

8. How deep should my cut be when planing end grain?

Keep the depth of cut minimal to prevent excessive tearout and ensure a smoother finish.

9. What should I do if I experience snipe when planing?

To avoid snipe, ensure that you maintain consistent pressure while feeding the board through the planer.

10. Are there any specific knife requirements for planing end grain?

Using sharp knives is crucial when planing end grain to achieve a cleaner cut and reduce the risk of tearout.

Do Benchtop Planers Significantly Increase Workshop Noise Levels?

FAQs on Benchtop Planers and Workshop Noise Levels

1. How loud are benchtop planers?

Benchtop planers typically produce noise levels between 85 to 95 dB, comparable to a loud vacuum or small power tool.

2. Do I need hearing protection when using a benchtop planer?

Yes, it is advisable to wear hearing protection during extended use to safeguard your hearing from prolonged exposure to high decibel levels.

3. Can I reduce noise from a benchtop planer?

Placing the planer on rubber feet can help minimize vibration noise, which reduces overall sound levels during operation.

4. Does using a dust collection system affect noise levels?

Utilizing a dust collection system not only helps manage airborne debris but can also contribute to a slight reduction in noise levels while operating the planer.

5. What techniques can minimize harsh sounds?

Keeping panels shorter and feeding them steadily through the planer can help reduce harsh, intermittent noises during the planning process.

6. Are all benchtop planers equally noisy?

Noise levels can vary based on the motor size and cutter speed of the planer, so some models may be quieter than others.

7. What is the impact of vibration on noise levels?

Vibration from the machine can contribute to increased noise levels; using padded surfaces can help absorb some of this vibration and reduce sound.

8. Is it safe to use a benchtop planer without hearing protection?

While it’s possible to use a benchtop planer without hearing protection, it is not recommended due to the potential risk of hearing damage from the high noise levels.

9. How often should I use a dust collection system with my planer?

It’s best to use a dust collection system consistently whenever using the planer to keep the workspace clean and help manage both dust and noise.

10. What is the best way to maintain a quiet workshop while using a planer?

Implementing soundproofing materials in the workshop and strategically placing the planer can help maintain a quieter environment while using the machine.

What Maintenance Schedule Prevents Blade Corrosion and Alignment Issues?

FAQs on Maintenance Schedule for Blade Corrosion and Alignment Issues

1. How often should I clean and oil my blades?

Blades should be cleaned and oiled after every 5–10 hours of use. Regular maintenance helps to prevent corrosion and ensures optimal performance.

2. What should I do if my blades need sharpening?

Inspect your blades regularly and sharpen or replace them as needed to maintain cutting efficiency. Dull blades can lead to increased wear and potential damage.

3. How do I keep cutterheads and feed rollers clean?

Wipe down cutterheads and feed rollers after each session to remove resin and dust. This practice helps to maintain smooth operation and prolongs the lifespan of your equipment.

4. When should I check blade alignment?

Blade alignment should be checked monthly to ensure precision cutting. Misalignment can lead to uneven wear and potential damage to the blades.

5. What is the importance of checking table flatness?

Monthly checks of table flatness are essential for consistent cutting results. An uneven table can cause alignment issues and affect the quality of the finished product.

6. How often should I check belt tension?

Belt tension should be inspected monthly as well. Proper tension ensures that blades operate smoothly and reduces the risk of slippage or misalignment.

7. What type of oil should I use for exposed metal parts?

Apply a light machine oil to exposed metal parts monthly to prevent rust. This simple step is crucial for protecting your equipment against corrosion.

8. What should I do for annual maintenance?

Annually, disassemble your equipment for a thorough inspection and deep clean. If you’re unsure about any aspects, consider professional tuning for optimal performance.

9. Why is regular maintenance important?

Regular maintenance prevents blade corrosion and alignment issues, ensuring the longevity and efficiency of your equipment. It also helps to avoid costly repairs or replacements.

10. How can I tell if my equipment needs professional servicing?

If you notice persistent alignment issues, unusual noises, or decreased cutting performance, it may be time for professional servicing. Regular checks can help you catch these problems early.

Final Thoughts

You’ve seen five reliable benchtop planers that suit beginners—each balances power, accuracy, and value so you can get consistent results without a steep learning curve. Choose DEWALT or CRAFTSMAN for proven durability, Cutech for a quieter, smoother cut, and WEN or VEVOR if portability and budget matter most. Consider cutterhead type, motor power, snipe reduction, and dust collection to match your projects, then start practicing to build confidence and skill.