Are you a woodworking enthusiast navigating the challenges of a small garage workspace? Finding the right bench vise can transform your cramped area into a more functional and efficient shop without compromising on clamping strength.

In this guide, we’ll explore the best woodworking bench vises designed specifically for tight spaces, ensuring you have the right tools to tackle hardwoods and light metalwork.

When selecting the ideal bench vise, compactness, sturdiness, and versatility are key. Look for models that offer features like swivel bases for flexibility, replaceable jaws for longevity, and a low profile to maximize usability in tight quarters.

These qualities not only enhance your workspace but also enable you to take on a variety of projects with confidence.

To help you make an informed decision, we’ve curated a list of six top-performing vises that meet these criteria. Each pick balances practicality and durability, ensuring they fit seamlessly into your small shop while handling real woodworking tasks with ease.

Ready to discover the right bench vise for your garage? Scroll down to check out our top picks!

IQ Vise 360° Articulating Bench Vise (Steel & Cast Aluminum, 8-Position Locking Ball & Socket)

If you’ve got a small garage and need a vise that maximizes positional flexibility without taking up a lot of space, the IQ Vise 360° Articulating Bench Vise is a strong choice: its hardened steel and cast-aluminum construction keeps the unit lightweight yet durable, while the 360° articulating ball with an 8-position locking system and Quick Cam lets you lock work at virtually any angle for plumbing, woodworking, or metal tasks. You’ll appreciate its compact 11.42 x 13.13 x 9.25-inch footprint and 10-pound weight, plus dual Flex-Fit jaws for flat or round stock, accessories compatibility, and high user ratings.

Best For: DIYers and hobbyists with limited workspace who need a compact, highly positionable bench vise for light-to-moderate plumbing, woodworking, and metal tasks.

Pros:

- 360° articulating ball with 8-position locks and Quick Cam offers exceptional positioning flexibility.

- Durable yet lightweight hardened steel and cast-aluminum construction with dual Flex-Fit jaws for flat and round stock.

- Compatible with task-specific accessories (soft jaws, work light, magnifier, phone holder) and highly rated by users.

Cons:

- Not suitable for heavy-duty industrial use or very high-torque applications.

- Reduced maximum jaw opening when using soft/replaceable jaws.

- Higher price point compared with basic vises, which may deter budget-conscious buyers.

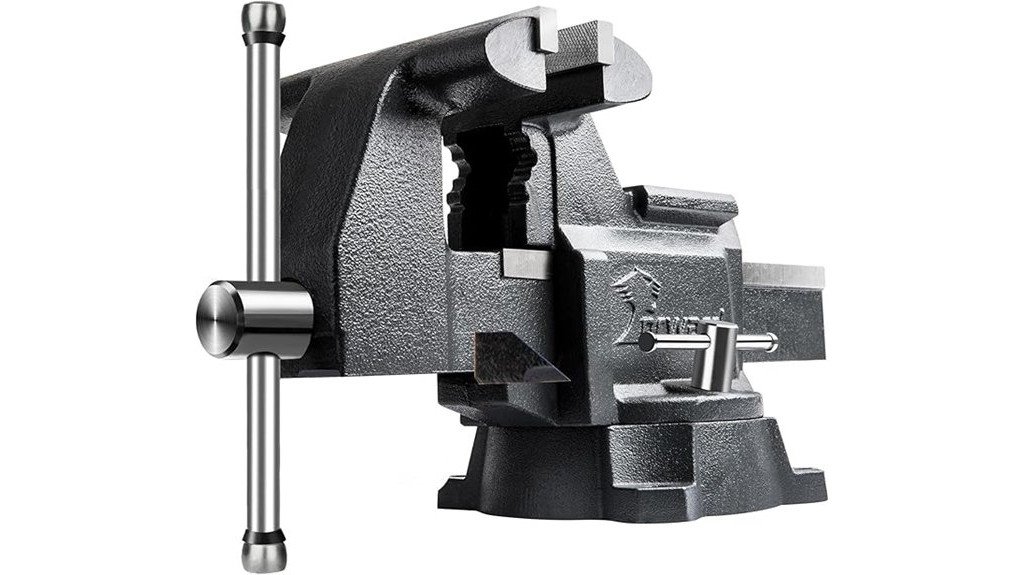

Forward CR40A 4.5 Inch Heavy Duty Bench Vise with Anvil and 210° Swivel Base

For small-garage woodworkers who need a compact but powerful vise, the Forward CR40A 4.5-inch Heavy Duty Bench Vise stands out for its combination of a 210° swivel base and a robust ductile-iron construction that delivers up to 6,600 pounds of clamping force. You’ll appreciate the 4.5-inch jaw width, 5-inch opening, and 2.6-inch throat depth for most bench tasks, plus replaceable serrated jaws and built-in pipe jaws for versatility. The large anvil and solid lockdown give reliable support, and the smooth sliding action aids precision. Note weight, possible rusting, and routine lubrication to maintain performance.

Best For: Small-garage woodworkers and DIYers who need a compact, heavy-duty bench vise with a swivel base and built-in pipe-jaw versatility.

Pros:

- Durable ductile-iron construction with up to 6,600 lbs clamping force for secure holding.

- 210° swivel base, replaceable serrated jaws, and built-in pipe jaws increase versatility for many tasks.

- Compact footprint (4.5″ jaw width, 5″ opening) with a large anvil and smooth sliding action for precision work.

Cons:

- Prone to surface rust without routine maintenance and lubrication.

- Heavier (≈19 lb) for its size, which may require a sturdy bench and more effort to mount.

- Throat depth (2.6″) and 4.5″ jaw width limit capacity for very large workpieces.

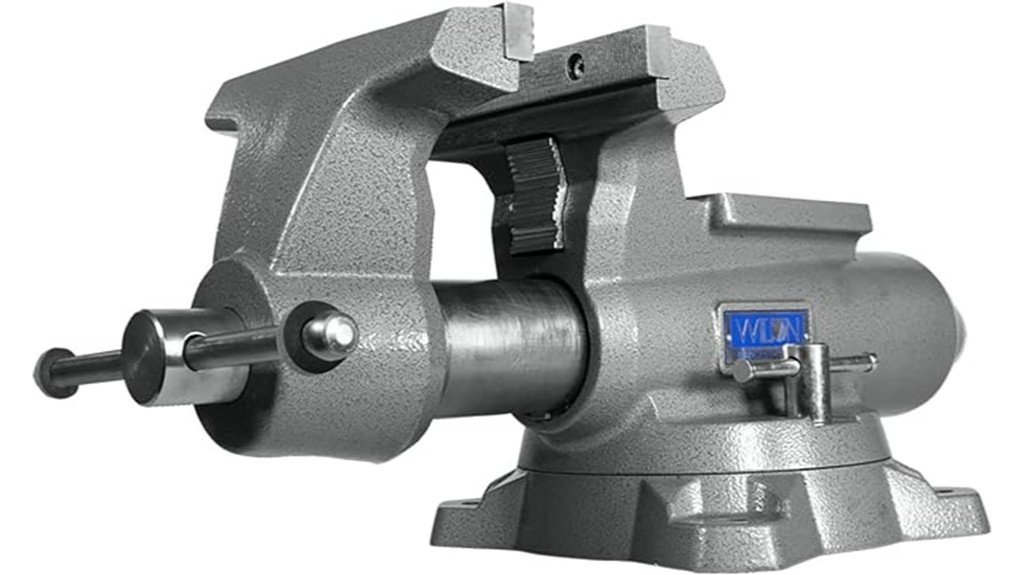

Wilton Mechanics Pro Bench Vise (Model 880M)

Built for serious hobbyists and small-shop pros who need industrial clamping power in a compact footprint, the Wilton Mechanics Pro 880M combines a 60,000 psi ductile iron movable jaw with a precision-machined slide bar and needle roller thrust bearing to deliver high clamping force with minimal flex and effort. You’ll find an 8-inch jaw width, 8-1/2-inch opening and 4-1/2-inch throat in an 83-pound, hand-powered package that feels solid yet manageable. The enclosed spindle, 360° swivel base with double lockdowns and large anvil add versatility, while a lifetime warranty backs durability despite occasional shipping complaints.

Best For: Serious hobbyists and small-shop professionals who need durable, high-clamping-force bench vise performance in a compact, versatile package.

Pros:

- 60,000 psi ductile iron construction, precision-machined slide bar, and needle roller thrust bearing for high clamping force with minimal flex and effort.

- Enclosed spindle, 360° swivel base with double lockdowns, and large anvil increase versatility for many metalworking and striking tasks.

- Backed by Wilton’s lifetime warranty and strong user reviews highlighting durability and performance.

Cons:

- Reports of poor packaging and occasional shipping damage (bent handles, etc.) on delivery.

- At 83 pounds, still heavy and may require assistance for mounting or positioning.

- Some users note initial handling or setup difficulties out of the box.

VEVOR 6-Inch Bench Vise with 360° Swivel Base and Anvil (Heavy Duty)

The VEVOR 6-inch bench vise stands out for anyone who needs a heavy-duty, space-conscious clamping solution in a small garage, since its 360° swivel base and 6-inch jaws let you position workpieces precisely without rearranging your bench. You’ll appreciate the forged 60,000 PSI ductile iron body, powder coating for rust resistance, and carbon steel jaw plates that are replaceable after heavy use. It clamps up to 20 kN, handles pipes and flat stock, and offers a 2.9 x 3-inch anvil for light hammering. Installation is straightforward, though you may need longer bolts for thick benches. Users report great value and durability.

Best For: anyone needing a heavy-duty, compact bench vise for DIY, small workshops, or garage work that requires versatile positioning and strong clamping.

Pros:

- Forged 60,000 PSI ductile iron body with powder coating and replaceable carbon-steel jaw plates for long-lasting durability.

- 360° swivel base and multi-jaw design (pipe and flat work) provide flexible positioning and versatility.

- High clamping force (up to 20 kN) and integrated 2.9 x 3-inch anvil for additional light-hammering tasks.

Cons:

- Included mounting bolts may be too short for thicker workbenches, necessitating extra purchases.

- Occasional user reports of minor jaw misalignment out of the box.

- At 25 lbs, heavier than some compact vises, which may be overkill for very light-duty hobbyists.

WORKPRO Dual Jaws Table Vise (2.5″ & 1.5″), 360° Swivel Clamp-On Mini Bench Vise for Woodworking and Metalworking

If you need a compact, versatile vise that won’t gobble up valuable bench space, the WORKPRO Dual Jaws Table Vise is a smart choice for hobbyists and DIYers working in small garages. You get two jaw options—2.5″ serrated and 1.5″ smooth—so you can grip pipes, wood, or delicate parts without swapping tools. The 360° swivel offers full positioning, and clamp-on or bolt-down mounting fits most benches. Built from ductile iron with hardened carbon steel jaws and a galvanized handle, it delivers up to 660 lbs of clamping force. Reviews praise its quality, though size may be limiting for some.

Best For: Hobbyists and DIYers with limited bench space who need a compact, versatile vise for woodworking, metalworking, and light-duty clamping tasks.

Pros:

- Dual jaws (2.5″ serrated and 1.5″ smooth) provide versatility for gripping pipes, wood, and delicate parts.

- 360° swivel and clamp-on or bolt-down mounting allow flexible positioning and easy installation on most benches.

- Durable construction (ductile iron body, hardened carbon steel jaws, galvanized handle) with up to 660 lbs clamping force.

Cons:

- Compact size may be too small for larger projects or heavy-duty shop work.

- Clamp-on compatibility and jaw opening may not fit all workbench edges.

- 1/4-20 bolts for bolt-down installation are not included.

PONY 5-Inch Heavy Duty Bench Vise with 360° Swivel Base and Anvil

For hobbyists who need a compact yet capable vise for tight workspaces, the PONY 5-inch Heavy Duty Bench Vise delivers reliable holding power in a small footprint, thanks to its 5-inch jaw width, 5-inch opening, and a 360° swivel base that lets you position work quickly without re-clamping. You’ll appreciate the cast-iron build and replaceable hardened steel serrated jaws, which grip securely for sawing, sanding, or gluing. The built-in anvil and pipe jaws add versatility, while cold-formed steel channel beams protect the screw. At about 25.6 pounds it’s portable, affordable, and well-reviewed for hobby use.

Best For: Hobbyists and DIYers who need a compact, portable bench vise with strong holding power for sawing, sanding, gluing, and light-to-moderate metal or wood work in tight workspaces.

Pros:

- 5″ jaws with replaceable hardened steel serrated faces provide secure grip for various tasks.

- 360° swivel base and compact footprint make positioning work quick without re-clamping.

- Built-in anvil and pipe jaws add versatility for shaping and holding round stock.

Cons:

- Cast-iron construction and finish reflect a light-duty, hobbyist-level fit and finish compared with professional-grade vises.

- 5″ size and 25.6 lb weight limit heavy-duty clamping — not ideal for very large or industrial jobs.

- Some users report minor fit-and-finish issues consistent with its price point.

Factors to Consider When Choosing Woodworking Bench Vises Small Garages

When you’re outfitting a small garage, start by matching the vise’s size and footprint to the available bench space so it won’t crowd your work area. Consider mounting options and jaw capacity range, along with material and durability, because a securely fastened, wear-resistant vise with the right opening will handle most projects reliably. Also look for multi-function features like swivel bases or replaceable jaws that boost versatility without adding bulk.

Size and Footprint

Start by measuring your available bench space and visualizing how a vise will fit into your workflow, since compact models typically span 8 to 16 inches in overall width and can dramatically affect how much usable surface you have left. Choose a low-profile vise with a minimal footprint to keep more clear workspace; that matters in tight garages where every inch counts. Check jaw width and maximum opening—most small vises offer 4 to 6 inches, enough for many woodworking tasks without monopolizing the bench. Consider weight: 10–25 pounds makes a vise portable and repositionable, while heavier units over 25 pounds give steadier clamping. Finally, confirm the design suits your bench so you can mount or clamp it securely without sacrificing bench utility.

Mounting Options

Although small garages demand compact solutions, choosing the right mounting style for a bench vise can make the difference between a clamped workpiece and a frustrating wobble, so you’ll want to weigh mobility, stability, and how your bench is built. Clamp-on vises are perfect if you need flexibility; they attach quickly without permanent changes, so you can relocate or store them when space is tight. Bolt-down vises give you superior rigidity for heavier work, but they require drilling into the bench and a sturdier support structure, which isn’t always possible in rented or lightweight benches. Integrated mounting, with pre-drilled holes or brackets, balances ease and stability and often suits purpose-built benches. Consider the vise’s weight, how you’ll use it, and your bench material before choosing.

Jaw Capacity Range

Having chosen how you’ll mount the vise, the next key specification to check is jaw capacity range, since that determines what size stock you can grip and how flexible the tool will be in a small garage setup. You’ll typically see jaw capacities from about 2.5 inches up to over 8 inches; smaller ranges like 2.5–5 inches suit compact workspaces and delicate projects, letting you clamp trim, small boards, and jig pieces without wasting bench space. If you want versatility, pick a vise with an adjustable jaw capacity or a wide maximum opening—often 5 inches to 8+ inches—so you can handle thicker stock when needed. Also consider replaceable jaws, which let you adapt to different materials and maintain secure clamping over years.

Material and Durability

Because your vise will take most of the physical work of holding stock, its material and construction matter more than you might think, especially in a small garage where you need gear that lasts and behaves predictably. Choose ductile iron or hardened steel for core components, since those materials resist wear and handle impacts better than cast alloys. Check the tensile strength rating — something around 60,000 psi signals the vise can withstand heavy clamping without deforming. Look for precision machining and a robust design so the screw and slide operate smoothly over years. Protective finishes like powder coating help prevent rust in humid conditions. Finally, prefer models with replaceable hardened jaw plates; they let you refresh the gripping surface without buying a whole new vise.

Multi-function Features

When space and flexibility matter in a small garage, a multi-function bench vise can be the difference between a cramped work area and a highly adaptable workspace; choose a model that combines features like dual-purpose jaws, a swivel base, and an anvil surface so you can clamp flat stock, grip round material, and perform light hammering without swapping tools. You’ll want dual jaws that offer serrated and smooth faces, giving secure hold on rough lumber and non-marring grip for finished pieces. A swivel base, ideally full 360-degree rotation, lets you approach work from any angle without moving the whole bench. An integrated anvil adds light shaping and hammering capability. Replaceable jaws allow task-specific customization, extending the vise’s usefulness across drilling, sanding, and pipe work.

FAQ

Can Bench Vises Be Safely Mounted to Thin Particleboard Workbenches?

FAQ 1: Can I mount a bench vise directly to thin particleboard?

No, it’s not advisable to mount a heavy bench vise directly to thin particleboard as it may split or tear under load.

FAQ 2: What happens if I mount a vise directly on particleboard?

Mounting a vise directly on particleboard can lead to structural failure, resulting in damage to both the workbench and the vise itself.

FAQ 3: How can I reinforce a particleboard workbench for a bench vise?

You can reinforce the area by using a hardwood block or creating a plywood sandwich to distribute the load more evenly.

FAQ 4: What type of fasteners should I use for mounting a vise?

Use large washers with bolts to secure the vise, as they help distribute the load and prevent crushing of the particleboard.

FAQ 5: Should I use glue when installing a bench vise?

Yes, applying glue in conjunction with fasteners can enhance the stability of the installation and reduce flexing.

FAQ 6: Is it necessary to back the assembly for a vise installation?

Backing the assembly with a metal plate or sacrificial backing is recommended to further distribute the stress and improve safety.

FAQ 7: How can I ensure my vise installation is safe?

Make sure to securely distribute fasteners and use reinforcing materials to provide a stable and safe installation for your vise.

FAQ 8: What materials should I avoid when mounting a vise?

Avoid using thin particleboard without reinforcement, as it is prone to splitting and may not support the weight of the vise.

FAQ 9: How can I tell if my workbench can support a vise?

Evaluate the thickness and quality of the material; if it’s thin or low-quality, reinforcement is essential for safe mounting.

FAQ 10: What is the benefit of using a plywood sandwich for reinforcement?

A plywood sandwich helps to distribute the load more evenly across a larger area, reducing the risk of damage to the particleboard.

FAQ 11: Can I use any type of wood for reinforcement?

It’s best to use hardwood for reinforcement due to its strength and durability, ensuring a more reliable installation for your bench vise.

Do Any Vises Include Quick-Release Mechanisms for Rapid Jaw Adjustment?

1. What is a quick-release mechanism in a bench vise?

A quick-release mechanism allows for rapid repositioning of the vise jaws without the need to fully thread the screw. This feature enhances efficiency during work.

2. Which types of vises typically have quick-release mechanisms?

Quick-release mechanisms are commonly found in both woodworking and metalworking bench vises. These models are designed to facilitate faster adjustments.

3. How does a quick-release mechanism work?

It typically operates through a sliding bar or a split-screw design that disengages the movable jaw. This design allows for quick adjustments while maintaining usability.

4. Are quick-release vises less powerful than standard vises?

Yes, vises with quick-release mechanisms may provide slightly less clamping power compared to those with full-thread engagement. This trade-off is often accepted for increased speed.

5. What should I consider before purchasing a vise with a quick-release feature?

Check the model specifications for jaw width, travel distance, and release durability. These factors will help you determine if the vise meets your specific needs.

6. Can quick-release vises handle heavy-duty tasks?

While many quick-release vises can handle a variety of tasks, those requiring heavy clamping power might be better served by traditional vises with full-thread engagement.

7. Is maintenance required for quick-release mechanisms?

Yes, regular maintenance is recommended to ensure the quick-release mechanism functions smoothly over time. Lubrication and cleaning can help maintain its efficiency.

8. Are quick-release vises suitable for precision work?

They can be suitable for precision tasks, but users should be aware of the reduced clamping power. It’s important to ensure the workpiece is held securely during detailed work.

9. What is the advantage of using a quick-release vise?

The primary advantage is the significant time savings when adjusting jaws between workpieces. This feature is particularly beneficial in high-volume or repetitive tasks.

10. Do all bench vises come with quick-release mechanisms?

No, not all bench vises include this feature. It is advisable to check product descriptions to confirm whether a vise has a quick-release mechanism before purchasing.

Which Vises Are Best for Delicate or Finished Wood Without Marring?

FAQs on Vises for Delicate or Finished Wood:

1. What type of jaws are best for delicate wood?

Soft jaws or removable protective pads are ideal for preventing marring on delicate wood surfaces.

2. Are there specific materials I should look for in jaw inserts?

Look for vises that feature inserts made of leather, rubber, or wood, as these materials help protect the wood from damage.

3. Why are wide, flat jaws important?

Wide, flat jaws distribute pressure evenly across the workpiece, reducing the risk of dents or scratches.

4. What type of vise is recommended for woodworking?

Dedicated woodworking vises with lined jaws are preferred, as they are designed specifically to accommodate delicate finishes.

5. Can cast-iron vises be used without damaging wood?

Yes, cast-iron vises with replaceable wooden jaws can be safe for delicate wood if the wooden jaws are properly maintained.

6. What features should I look for in a quick-release vise?

Ensure the quick-release model allows for the attachment of soft pads, which will help protect the wood while providing a secure grip.

7. How should I clamp delicate wood pieces?

Always clamp lightly to avoid excessive pressure that can lead to marring or damage.

8. What technique can help with alignment during clamping?

Regularly check the alignment of your workpiece as you clamp to ensure it remains secure without causing harm.

9. What are cauls, and how do they help?

Cauls are auxiliary pieces of wood that can be used alongside the workpiece to provide extra support and even pressure, especially for long pieces.

10. How can I avoid marring while maintaining a secure grip?

Use the right vises and techniques, such as soft jaws and cauls, to create a balance between grip strength and surface protection.

Can These Vises Accommodate Pipe or Round Stock Without Extra Jaws?

1. Can woodworking bench vises hold pipe or round stock?

Yes, many woodworking bench vises can accommodate pipe or round stock without the need for extra jaws.

2. How does the performance of vises vary with round stock?

Performance can vary among different vise types; some may grip more effectively than others depending on their design.

3. What issues might arise with standard metal vises?

Standard metal vises with flat serrated jaws may crush or mar softer pipes, potentially damaging the material.

4. Are there specific vises designed for pipe?

Yes, there are pipe-capable designs specifically made to hold round stock securely without damaging it.

5. What are V-grooves and how do they help?

Some vises feature built-in V-grooves that are designed to securely grip tubing and round stock.

6. What is a quick-change vise?

Quick-change or multi-purpose vises are designed for versatility and typically provide better grip on round materials.

7. How can I prevent marking on finished wood while using a vise?

To protect finished wood, you can add leather or wooden jaw pads to the vise, which will help secure the work without causing damage.

8. Do I need extra jaws for round stock?

In many cases, extra jaws are not necessary, but choosing the right vise design is important for optimal performance.

9. Will all vises handle all sizes of pipe?

Not all vises are suitable for all sizes of pipe; it’s essential to check the specifications of the vise to ensure compatibility.

10. What materials are recommended for protective covers?

Soft protective covers are recommended for standard metal vises to prevent marring when gripping softer materials.

Are There Recommended Rust-Prevention Steps for Coastal Climates?

1. How often should I seal and maintain my vises in coastal climates?

Regular maintenance is essential in coastal areas. It’s recommended to seal and maintain vises frequently to prevent rust.

2. What should I do after using my vises?

After each use, wipe your vises clean to remove moisture and debris. This helps minimize the risk of rust formation.

3. What type of oil should I apply to my vises?

Apply a light coat of oil or a corrosion inhibitor to the screw, guides, and jaws for effective protection against rust.

4. How can I protect the cast parts of my vises?

Use a silicone or wax protectant on the cast parts to provide an additional layer of defense against corrosion.

5. Is it better to store vises covered or uncovered?

Always store vises covered or indoors when possible to shield them from the elements and reduce exposure to moisture.

6. What should I do to keep the screw of my vise functional?

Run the screw occasionally to ensure that all parts remain moving smoothly and are not prone to seizing or rusting.

7. How can I enhance the longevity of my vise jaws?

Consider replacing or upgrading jaw plates with stainless steel or coated options, as these materials are more resistant to rust and wear.

8. What environmental factors contribute to rust in coastal climates?

High humidity and salty air in coastal areas significantly increase the likelihood of rust formation on metal tools like vises.

9. Are there specific products recommended for corrosion protection?

Look for specialized corrosion inhibitors and protectants designed for metal surfaces that can offer enhanced protection against rust.

10. What signs indicate that my vise may be rusting?

Look for discoloration, pitting, or a rough texture on the surface of the vise. These are common indicators that rust may be developing.

Final Thoughts

You’ll want a vise that fits your bench and the projects you do, so pick one that balances compact size with durable construction and useful features like swivels, replaceable jaws, and an anvil. For tight garages, prioritize lightweight but sturdy models such as the IQ Vise or Forward CR40A, or choose versatile options like Wilton or VEVOR for heavier work. With the right vise, you’ll maximize space without compromising capability or safety.