Are you a DIY enthusiast working in your home garage? If so, finding the right table saw can make all the difference in achieving precision cuts while ensuring safety and maximizing your workspace.

With so many options available, it can be overwhelming to sift through the choices. That’s where we come in! This guide will help you discover the best table saws tailored for home garages, focusing on the essential aspects of precision, power, and safety.

In this roundup, we’ll explore three standout models: the compact 10″ MarvTool for those with limited space, the robust DEWALT DWE7485 perfect for larger rips, and the BOSCH GTS15-10, which is renowned for its stability and accuracy.

We’ll break down their key features, advantages, and any trade-offs, allowing you to make an informed decision that suits your specific needs and setup.

No matter if you’re a seasoned woodworker or just starting out, selecting the right table saw is crucial for your projects. Each model we review balances performance with safety, ensuring that you can work confidently without compromising on quality.

Ready to find the perfect table saw for your garage? Scroll down to dive into our top picks!

15Amp Portable 10-Inch Portable Table Saw for Woodworking and DIY Furniture Making

If you’re outfitting a home garage for woodworking or DIY furniture projects, the MarvTool 15Amp 10-inch portable table saw stands out for its balance of power and portability — a workhorse that won’t dominate your workspace. You’ll get a 15A motor spinning a 36T, 10-inch blade at 4600 RPM, handling hardwoods, plywood, OSB, thin aluminum and PVC. Blade height and tilt (0–45°) let you cut up to 3.4″ at 90° and 2.1″ at 45°. At 28.3 pounds it’s compact and easy to move; a transparent guard, dust port, and manual support safer operation. Reviews praise convenience, though some note stability and motor concerns.

Best For: Home hobbyists and DIY furniture makers who need a portable, reasonably powerful table saw for small to medium projects in limited workshop space.

Pros:

- Compact and lightweight (28.3 lbs) for easy transport and storage.

- Strong 15A motor (4600 RPM) and 10″ 36T blade suitable for hardwoods, plywood, OSB, thin aluminum and PVC.

- Adjustable blade height and bevel (0–45°) with transparent blade guard and dust port for safer, cleaner operation.

Cons:

- Some users report motor reliability issues over time.

- Miter slots and overall stability can be lacking for larger or more demanding jobs.

- Limited cutting depth (3.4″ at 90°, 2.1″ at 45°) may not suit thicker stock.

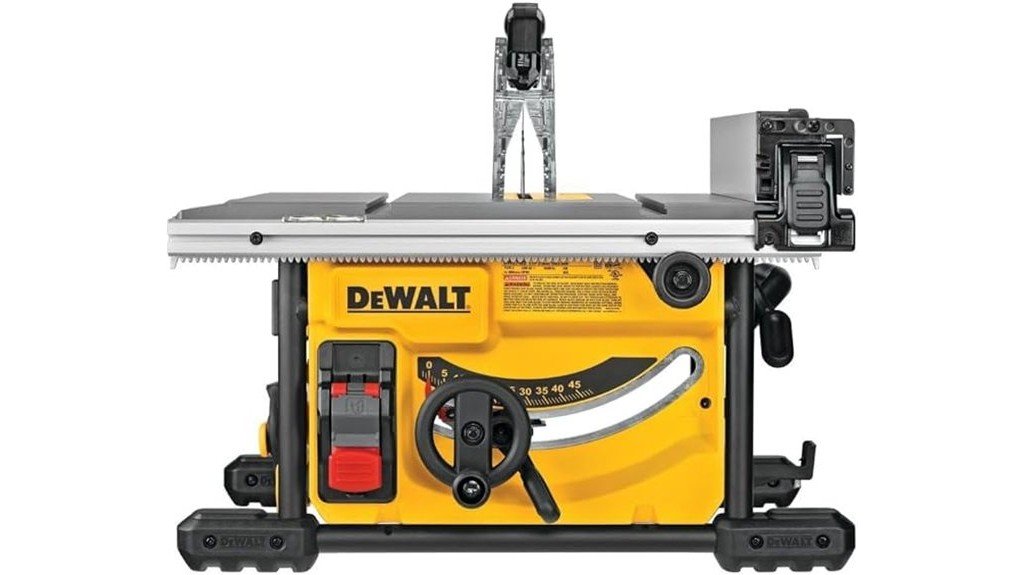

DEWALT 15 Amp 8-1/4 in. Compact Portable Jobsite Table Saw (DWE7485)

For home garage owners who need a powerful but portable table saw, the DEWALT DWE7485 stands out for its 15-amp motor and 24.5-inch rip capacity, which lets you rip full 4×8 sheets without a larger station saw. You’ll get 5800 RPM and 1800 watts in a compact 54-pound package, with rack-and-pinion telescoping fence rails for fast, accurate adjustments. The Site-Pro modular guarding system and power-loss reset boost safety, while on-board storage and a metal roll-cage base aid jobsite durability. Reviewers praise its power and portability, though some note miter gauge accuracy and vertical fence limits.

Best For: Home garage owners and jobsite contractors who need a powerful yet portable table saw capable of ripping full 4×8 sheets and handling medium-sized projects.

Pros:

- 15 Amp motor (5800 RPM, 1800 W) with 24.5″ rip capacity lets you rip full 4×8 plywood or OSB in a compact 54-lb package.

- Rack-and-pinion telescoping fence rails deliver fast, smooth, and accurate adjustments; Site-Pro modular guarding and power-loss reset enhance safety.

- On-board storage and a metal roll-cage base increase jobsite durability and portability.

Cons:

- Miter gauge accuracy is reported inconsistent by some users.

- No vertical fence adjustment, which can limit fine fence alignment.

- Compact size may be less stable than larger cabinet or contractor saws for very heavy-duty use.

BOSCH 10-Inch Portable Jobsite Table Saw with Gravity-Rise Wheeled Stand

Home-garage woodworkers who need a reliable, portable saw that handles larger ripping jobs will appreciate the Bosch GTS15-10, whose 15-amp motor and 32-1/8-inch rip capacity make it a strong choice for furniture projects and framing tasks. You’ll get a 10-inch carbide 50-tooth blade spinning at 3,800 RPM, electronically regulated to hold speed under load, and soft-start circuitry to reduce breaker trips. The gravity-rise wheeled stand and single-action setup move the 102.7-pound unit easily, while the rack-and-pinion fence and Smart Guard system boost accuracy and safety. Most users praise cutting performance; a few noted minor alignment or parts issues.

Best For: Home and jobsite woodworkers who need a portable yet powerful table saw for larger ripping jobs, furniture builds, and framing tasks.

Pros:

- 15-Amp motor with electronically regulated 3,800 RPM maintains speed under load for consistent cuts.

- Gravity-rise wheeled stand and single-action setup make transport and setup quick and easy.

- Rack-and-pinion fence and Smart Guard safety features (riving knife, anti-kickback pawls) improve accuracy and safety.

Cons:

- At 102.7 lb, still relatively heavy for frequent lifting despite the wheeled stand.

- Some users report occasional minor alignment issues out of the box.

- Reports of missing parts for some buyers, requiring customer service or returns.

Factors to Consider When Choosing Table Saws for Home Garages

When you’re choosing a table saw for your garage, start by matching motor power and RPM to the materials you’ll cut, since stronger motors and appropriate blade speeds keep cuts smooth and efficient. Consider blade size options and cutting capacity limits so you can handle wide boards and different profiles, and make sure the fence is accurate because it directly affects repeatability and safety. Finally, prioritize safety features like blade guards, riving knives, and reliable emergency stops—these reduce risk and give you confidence during tougher projects.

Power and RPM

A clear understanding of a table saw’s power and RPM will help you pick a machine that matches the projects you plan to tackle, from trimming plywood to ripping hardwood. Power, measured in amps for most portable and benchtop models, tells you how much sustained work the motor can handle; a 15-amp saw will manage many hardwoods and plywood sheets without struggling. RPM reflects blade speed—models running around 4600 to 5800 RPM cut faster and often cleaner, but speed alone isn’t everything. You want balance: sufficient amps for torque so the blade won’t bog down, paired with an RPM that maintains smooth cuts. Match power and RPM to the materials and thicknesses you’ll cut most often for reliable performance.

Blade Size Options

Understanding motor power and blade speed helps you pick the right blade size for the work you’ll do, since blade diameter directly affects cut capacity and job flexibility. Blade sizes generally range from 8 to 10 inches, with 10-inch blades offering the most versatility for home garages. A 10-inch blade lets you crosscut thicker boards — roughly 3.4 inches at 90 degrees and about 2.1 inches at 45 degrees — so it’s a solid default if you want range. Smaller blades, like 8-1/4 inches, favor portability and lighter saws when you need to move equipment. Also consider tooth count: 36T cuts faster and is rougher, while 50T produces smoother finishes. Finally, match blade choice to your saw’s RPM, since motor speed influences cut quality and efficiency.

Cutting Capacity Limits

Five key limits define what you can cut on a table saw, and knowing them helps you match a model to your projects: maximum thickness (how deep a blade will plunge at 90° and 45°), rip capacity (how wide you can cut parallel to the blade), motor speed and torque (which affect how well the saw feeds through dense materials), blade size and tooth count (which influence cut smoothness and capacity), and adjustability features like blade height and bevel angle. You’ll check maximum thickness specs—some saws handle about 3.4″ at 90° and 2.1″ at 45°—to guarantee boards fit. Rip capacity varies widely; larger saws reach roughly 32-1/8″ for full plywood sheets. Higher RPM and robust torque help slice dense hardwoods, while a 10″ blade with more teeth gives cleaner finishes. Adjustable height and bevel let you perform crosscuts and beveled cuts within a saw’s limits.

Fence Accuracy Importance

Precision matters when you’re setting up a table saw fence, because even small deviations can turn a promising cut into wasted material or a safety hazard. You want a fence system that holds true to your measurements and stays stable under feed pressure; consistent alignment means repeatable, accurate cuts and less time reworking pieces. Look for advanced mechanisms, like rack-and-pinion fences, that let you make smooth, quick adjustments and lock securely. Check user feedback: many woodworkers flag fence accuracy as a top factor affecting project quality. Make sure the fence is easy to calibrate and maintains its setting during operation, since an inaccurate or drifting fence not only wastes materials and time but also increases the chance of binding and kickback.

Safety Features Needed

A reliable fence gives you accurate cuts, but safety features are what keep you cutting another day; when choosing a table saw for your garage, pay close attention to built-in protections that reduce the chance of injury and long-term health risks. Look for a transparent blade guard so you can see the kerf while preventing accidental contact, and pick a model with a dust port that connects to a shop vacuum to cut down airborne dust and respiratory hazards. Prefer saws with a power-loss reset so the machine won’t restart unexpectedly after an outage. Smart Guard Systems that include adjustable riving knives and anti-kickback pawls greatly reduce kickback and binding. Finally, choose a saw with a clear, detailed user manual so you understand safe operation from day one.

Portability and Weight

Think about portability and weight as practical compromises that determine where and how you’ll use your table saw: lighter models like the MarvTool at 28.3 pounds make it easy to move the tool in and out of a garage or truck, while compact but heavier jobsite saws such as the 54-pound DEWALT still offer manageable mobility with better stability. You’ll want to match weight to your workflow—if you move the saw frequently, prioritize lighter units or ones with wheeled, gravity-rise stands for quick setup. Check footprint and storage dimensions so the saw fits your garage without blocking access. Remember that very light saws can shift while cutting; plan for clamping, support stands, or anchoring to maintain accuracy and safety during larger jobs.

Dust Collection Options

While you’re setting up a table saw in a home garage, don’t overlook dust collection—effective systems keep your workspace clean, protect your lungs, and help the saw run reliably by stopping dust from gumming up moving parts. You’ll want a saw with a usable dust port that mates to a shop vacuum or dedicated collector, since direct capture at the blade greatly improves extraction. Good collection preserves air quality and reduces respiratory risk from fine dust, while keeping the table and controls visible so you make safer, more accurate cuts. Regularly emptying filters and clearing hoses prevents buildup that can shorten the saw’s life. Investing in a quality setup saves cleanup time and boosts productivity, so balance port size, suction, and filter quality when choosing.

FAQ

Can Table Saws Be Used Safely Outdoors in Rainy Conditions?

1. Can I use a table saw outside when it’s raining?

No, using a table saw outdoors in rainy conditions is highly unsafe due to the risks of electric shock and slipping on wet surfaces.

2. What hazards are associated with using a table saw in wet conditions?

Water creates a serious shock hazard when combined with electricity, and the risk of slipping increases significantly on wet ground.

3. Is there any way to work outdoors in damp weather with a table saw?

If you absolutely must work in damp weather, wait for conditions to improve, use a grounded GFCI circuit, and ensure the saw is covered with a waterproof canopy.

4. How can I keep my table saw dry during outdoor use?

To protect the saw, keep the blade and motor dry and use a waterproof covering whenever possible.

5. What personal protective equipment should I wear when using a table saw outdoors?

You should wear non-slip boots to prevent slipping, goggles for eye protection, and hearing protection to safeguard your hearing.

6. Are there any specific materials to avoid when using a table saw outdoors in damp conditions?

Avoid using metal workpieces, as they can corrode and conduct electricity, increasing the risk of shock.

7. What should I do if I need to work outside but it’s drizzling?

It’s best to postpone your work until the weather improves to ensure your safety and the safety of your equipment.

8. How can I ensure my workspace is safe when using a table saw outdoors?

Make sure the area is dry, free from obstacles, and set up on a stable surface to minimize the risk of accidents.

9. What type of electrical setup should I have for outdoor table saw use?

Always use a grounded GFCI circuit to protect against electrical shock when working outdoors.

10. Can I cover my table saw with anything besides a waterproof canopy?

While a waterproof canopy is ideal, you can also use tarp or heavy-duty plastic sheeting, but ensure it is securely fastened to prevent water from entering.

How Do Table Saws Compare to Track Saws for Cabinet Making?

1. What are the main advantages of using a table saw in cabinet making?

Table saws offer superior repeatable rip accuracy and faster throughput, making them ideal for precise joinery and consistent dados. They also provide better support for large panels.

2. When should I use a track saw instead of a table saw?

Track saws are perfect for breaking down sheet goods and cutting long, straight parts on-site. They minimize setup time, making them convenient for initial panel milling and on-site fits.

3. How do table saws and track saws differ in terms of panel support?

Table saws are designed to support large panels effectively, allowing for stable and accurate cuts. In contrast, track saws are more portable but may require additional support for larger pieces.

4. Can I use both a table saw and a track saw for cabinet making?

Yes, combining both tools in your workflow enhances efficiency and flexibility. Use the table saw for precision cuts and the track saw for initial breakdown and on-site adjustments.

5. What type of cuts can I achieve with a table saw?

A table saw excels at making precise cuts necessary for joinery and creating consistent dados. Its design allows for repeatable accuracy, essential for high-quality cabinet making.

6. Are track saws effective for on-site work?

Absolutely! Track saws are designed for portability and ease of use on-site, allowing for quick and accurate cuts without the need for extensive setup.

7. What is the benefit of using a track saw for initial panel milling?

Using a track saw for initial panel milling allows for quick, straight cuts without the need for heavy machinery. This speeds up the process and reduces the amount of material handling.

8. How do I decide which tool to use for specific cabinet making tasks?

Consider the task at hand: use a table saw for precise, repeatable cuts and joinery, while opting for a track saw for breakdown and on-site fitting tasks. Each tool serves distinct purposes.

9. Is setup time different between table saws and track saws?

Yes, setup time is generally quicker with track saws, making them ideal for mobile operations. Table saws may require more time for adjustments, especially when working with larger panels.

10. What is the overall benefit of using both a table saw and a track saw?

Using both tools allows for a comprehensive approach to cabinet making, maximizing efficiency and ensuring accuracy. Each tool complements the other, providing a flexible workflow for various tasks.

Can I Convert a Portable Table Saw Into a Benchtop Router Table?

1. Can I convert a portable table saw into a benchtop router table?

Yes, a portable table saw can be converted into a benchtop router table with the right modifications and accessories.

2. What parts do I need for the conversion?

You will need a compatible router insert plate, secure mounting brackets, and a dust collection system for effective operation.

3. How do I ensure the saw’s stability?

It’s essential to check that the saw’s top remains flat and stable after the conversion to ensure accurate routing.

4. What safety modifications are necessary?

You will need to modify the fencing and safety guards to accommodate router use, ensuring they effectively protect during operation.

5. How should I test the router setup?

Start by testing the router adjustments at low speed to ensure everything functions correctly before moving on to higher speeds.

6. Is dust collection necessary for this setup?

Yes, implementing a dust collection system is critical to maintain a clean workspace and improve visibility while routing.

7. How do I check arbor compatibility?

Verify the arbor compatibility by ensuring that the router and saw have matching sizes and thread types for secure attachment.

8. What precautions should I take against kickback?

Prioritize the use of shields and proper clamping to prevent kickback, which can be dangerous during routing operations.

9. Can I use existing table saw features in the router setup?

You can utilize existing table saw features, such as the table surface, but ensure they are still suitable for routing tasks.

10. Are there any specific tools needed for modification?

You may require specific tools like wrenches and screwdrivers to install the router insert and secure the mounting brackets during the conversion.

What Maintenance Schedule Prevents Motor Overheating in Frequent Use?

1. What weekly maintenance tasks should I perform to prevent motor overheating?

Each week, clean dust and debris from the motor, check blade alignment, inspect belts and cords for wear, and ensure that ventilation paths are clear to promote efficient cooling.

2. How often should I lubricate the motor’s moving parts?

Lubrication of bearings and moving parts should be done monthly to ensure smooth operation and reduce friction, which can lead to overheating.

3. What should I do if I notice my motor is overheating?

If the motor is overheating, reduce its duty cycle to allow it to cool down, and consult a technician if the problem persists.

4. Why is it important to check motor amperage under load?

Testing the motor’s amperage under load monthly helps identify potential issues with excessive current draw that can lead to overheating and damage.

5. How can I ensure proper ventilation for my motor?

Inspect ventilation paths monthly to ensure they are free from obstructions, which is crucial for maintaining optimal cooling and preventing overheating.

6. What are the signs that my motor’s belts and cords need inspection?

Look for signs of wear, fraying, or damage on belts and cords. Regular inspection helps prevent failures that could lead to overheating.

7. How often should I check the mounting bolts of my motor?

Monthly inspection and tightening of mounting bolts is important to keep the motor securely in place and reduce vibrations that could contribute to overheating.

8. What role do brushes or commutators play in motor maintenance?

Inspecting brushes and commutators monthly is essential as worn components can lead to poor electrical contact and increase operating temperatures.

9. What should I do if my motor continues to overheat despite regular maintenance?

If overheating persists, it is advisable to consult a technician for a thorough diagnosis, as there may be underlying issues that require professional attention.

10. Is there anything specific to monitor during frequent use of the motor?

During frequent use, pay special attention to heat buildup, the efficiency of cooling mechanisms, and any unusual sounds or vibrations, as they may indicate potential overheating issues.

Are There Insurance or Legal Requirements for Home Garage Woodworking?

1. Do I need to inform my insurance company about my woodworking hobby?

Yes, you should inform your insurance provider about your woodworking hobby to ensure you have proper coverage. Failing to do so may leave you unprotected in case of accidents or damages.

2. What kind of insurance should I check for my woodworking activities?

You should check your homeowners or renters insurance for hobby workshop coverage. This ensures that your tools and any potential liabilities are covered under your policy.

3. Does running a woodworking business from home change my insurance needs?

Yes, running a business from your home may void your standard homeowners policy. You will need to notify your insurer and potentially obtain a commercial policy.

4. Are there zoning laws that apply to home woodworking businesses?

Yes, zoning laws can affect whether you can operate a woodworking business from home. It’s important to check with local authorities to ensure compliance.

5. Do I need a business license for woodworking activities?

If you plan to sell your woodworking products, you may need a business license. Check your local regulations to determine the specific requirements for your area.

6. What local safety codes should I be aware of for woodworking?

Local safety codes may address emissions, noise, and electrical upgrades. Familiarize yourself with these codes to ensure your woodworking setup is compliant.

7. How can I document safety measures for my woodworking shop?

You can document safety measures by creating a checklist of protocols and maintaining records of safety equipment and training. This documentation can be useful if you face inspections or claims.

8. What are the potential consequences of not following legal requirements?

Failing to comply with insurance, zoning, or safety requirements can lead to fines, legal issues, or denied insurance claims. It’s crucial to stay informed to avoid costly violations.

9. Should I consult with my insurer about woodworking safety measures?

Yes, consulting with your insurer about safety measures can help ensure you have adequate coverage. They can provide guidance on best practices for risk management.

10. Is noise from woodworking a concern for my neighbors?

Yes, noise from woodworking can be a concern, especially if you live in a residential area. Be aware of local noise ordinances and consider soundproofing measures if necessary.

Final Thoughts

You’ve seen compact, mid‑range, and heavy‑duty options that suit most garage workshops, so choose based on the projects you’ll tackle: pick the MarvTool for portability and small builds, the DEWALT for ripping full sheets with power and capacity, or the BOSCH for precision and mobility on furniture work. Prioritize safety features, fence accuracy, and dust control, and you’ll get reliable performance that balances power, precision, and long‑term value.