Are you a beginner woodworker looking to create a cleaner, healthier workspace without breaking the bank? If so, you’re in the right place! In this guide, we’ll explore three top-rated air filtration units that effectively tackle the fine dust and airborne particles that can settle on your tools and pose risks to your lungs.

Choosing the right filtration system is crucial for maintaining a safe and pleasant woodworking environment. You don’t need to invest in industrial-grade equipment to achieve impressive results. Instead, we’ll focus on affordable options that provide an ideal balance of airflow, filtration efficiency, and noise levels, ensuring you can work comfortably and productively.

Whether you’re setting up a small shop in your garage or a dedicated woodworking space, the right air filtration unit can make a world of difference. With our curated selection, you’ll find systems that fit your unique needs and workflow.

Ready to discover the best air filtration units for your woodworking shop? Scroll down to explore our top picks!

Abestorm 270 Degree Air Filtration System (DecDust 1080IG)

If you run a busy woodworking shop and need fast, reliable air cleanup, the Abestorm 270 Degree Air Filtration System (DecDust 1080IG) is built for that workload: its 1080 CFM vortex fan and ionic-assisted MERV-11 filtration pull large volumes of dust and fine micron particles out of the air quickly, while the ionizer reduces filter clogging and extends filter life so you spend less time on maintenance. You’ll appreciate two-speed control, compact 22 lb portability, and wall or ceiling mounting options. The ionizer boosts capture efficiency and cuts fan load, lowering energy use, though filter availability and cost merit checking.

Best For: busy woodworking shops, garages, and workshops that need high-volume, fast dust and fine-particle removal with low-maintenance filtration.

Pros:

- 1080 CFM vortex fan plus ionic-assisted MERV-11 filtration captures large particles and fine micron dust effectively.

- Ionizer reduces filter clogging, extending filter life 2–3× and lowering fan load for energy savings.

- Compact 22 lb design with two-speed control, remote, and wall/ceiling mounting options for flexible placement.

Cons:

- Replacement filter availability and cost can be a concern for some users.

- Ionic technology may require occasional cleaning to manage collected dirt and maintain performance.

- Ceiling installation may need additional heavy-duty mounting hardware for safe suspension.

WEN 3410 Remote-Controlled Air Filtration System (400 CFM)

For woodworkers who need a balance of strong performance and convenient control, the WEN 3410 Remote-Controlled Air Filtration System stands out thanks to its 300/350/400 CFM three-speed motor and remote operation that lets you change settings from up to 26 feet away. You’ll get effective dust capture across up to 400 sq ft with a quiet 50–60 dB profile, a lightweight 31-pound body, and easy mounting. Filters include a 1-micron inner and 5-micron pre-filter, both replaceable; replacement packs cost about $65. The unit is simple to install, offers a programmable timer, and includes a two-year warranty.

Best For: Woodworkers and small workshop owners who want a powerful, quiet, and remotely controllable air filtration unit to reduce dust across up to 400 sq ft.

Pros:

- Three-speed (300/350/400 CFM) motor with remote control and programmable timer for flexible, convenient operation.

- Quiet (50–60 dB) and lightweight (31 lb) design with easy mounting and portability.

- Effective filtration with 1‑micron inner and 5‑micron pre-filter, improving air quality in workshops.

Cons:

- Replacement filters can add ongoing cost (≈ $65 per two-pack).

- Coverage limited to about 400 sq ft, may be insufficient for larger shops.

- Not designed for heavy industrial environments despite strong performance for small workshops.

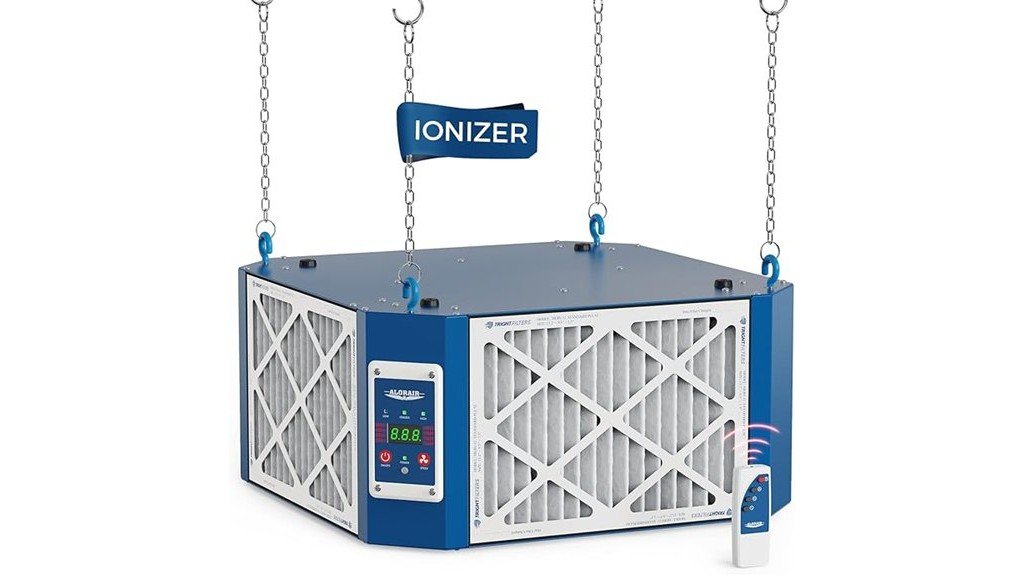

AlorAir 360° Intake Air Filtration System (1350 CFM) with Vortex Fan and Built-in Ionizer – Shop Dust Collector

Woodworkers who need high airflow and thorough particle capture will appreciate the AlorAir Purecare 1350IG, a 360° intake filtration unit that’s built to handle heavy dust loads in medium to large shops. You’ll get up to 1350 CFM from a strong vortex fan with two speeds, covering roughly 1,700 sq ft while maintaining static pressure during heavy use. The MEVR 11 filter traps most 1–10 µm particles and a built-in ionizer helps reduce odors and volatile pollutants. It’s compact and portable at 27 lb, includes a timer and remote, and installs quickly—just upgrade mounting hardware for safety.

Best For: Woodworkers and small-to-medium shop owners who need high airflow and effective capture of 1–10 µm dust in spaces up to about 1,700 sq ft.

Pros:

- Delivers up to 1,350 CFM with a strong vortex fan and two-speed settings to maintain performance under heavy dust loads.

- 360° intake and MEVR 11 filter capture most 1–10 µm particles; built-in ionizer helps reduce odors and VOCs.

- Compact and portable (27 lb) with timer, IR remote, and easy hanging installation.

Cons:

- Filter only rated MEVR 11 (not HEPA), so finer sub-micron particles may not be fully captured.

- Included mounting hardware may be insufficient for long-term safety — heavy-duty hardware often needed.

- Not eligible for shipping to California and produces 60–69 dB noise, which may be loud for some shop environments.

Factors to Consider When Choosing Air Filtration Units for Beginner Woodworkers

As a beginner woodworker, you’ll want to weigh several practical factors—like filtration efficiency ratings to know what particle sizes are captured and airflow capacity (CFM) to guarantee your workspace gets adequate turnover. Consider which filter types you need for wood dust and finishing fumes, how loud the unit will be during long sessions, and whether installation and mounting fit your shop layout. These choices will help you pick a system that’s effective, comfortable to live with, and easy to set up.

Filtration Efficiency Ratings

While choosing an air filtration unit, you’ll want to pay close attention to filtration efficiency ratings because they tell you how well a unit captures the range of particle sizes produced in a shop. Ratings like MERV give a clear benchmark: higher numbers mean better capture of fine dust. A MERV 11 filter, for example, stops roughly 90% of 3–10 μm particles and about 85% of 1 μm particles, which matter for respiratory health. Some units add ionizers to boost capture of micron-sized particulates via electrostatic attraction, improving overall efficiency. Remember that particle size varies from visible chips to invisible fines, so choose higher-rated filters for health protection. Finally, replace and maintain filters on schedule — clogged media cuts performance fast.

Airflow Capacity (CFM)

1 clear metric you’ll want to check is airflow capacity, measured in cubic feet per minute (CFM), because it tells you how much air the unit can cycle and filter each minute — a higher CFM means faster removal of airborne dust and fines. You should match CFM to shop size: about 400 CFM can adequately handle smaller spaces up to roughly 400 sq ft, while larger areas may need 1000 CFM or more, with systems around 1350 CFM suitable for spaces approaching 1700 sq ft. Higher CFM improves particle removal and lowers health risks from prolonged dust exposure, but it often raises noise, so consider how loud you can tolerate. Balance capacity, coverage area, and comfort to pick a unit that cleans efficiently without disrupting your workflow.

Filter Types Needed

Airflow capacity tells you how fast a unit moves air, but the filters themselves determine what stays out of your lungs — so you’ll want to pay close attention to filter types when choosing a system for woodworking. Aim for MERV-11-rated filters; they capture fine particles and most wood dust, noticeably improving air quality. Look for filters rated to trap 1-micron and 5-micron particles to catch the smallest dust and common allergens in your shop. Consider electrostatic-assisted adsorption models, which reduce fan load and boost efficiency. Ionic technology can enhance particle capture and often cuts clogging, extending filter life by two to three times. Finally, choose systems with easily replaceable filters so you can maintain peak performance without hassle.

Noise Level Considerations

Because you’ll often run a filtration unit for long stretches while you work, noise becomes as important as filtration power; quieter systems in the 50–60 dB range help you stay focused and reduce fatigue, especially during detailed tasks. You should aim for units rated at 60 dB or lower to preserve concentration and avoid auditory strain, since many models span 50–70 dB. Look for machines with multiple speed settings so you can ramp up airflow for heavy dust and dial it back for delicate work, balancing performance and comfort. Remember that higher noise can distract you and harm workmanship, so prioritize quieter operation when possible, and compare manufacturer decibel ratings under realistic load conditions.

Installation and Mounting

When choosing an air filtration unit, think about how and where you’ll install it so the system works efficiently without crowding your workspace; wall-mounting or ceiling suspension can save valuable floor space and keep the unit out of the way of tools and material flow. Check the unit’s weight and installation dimensions to verify it fits your shop and that studs or joists can support it safely. Prefer models that include all mounting hardware, or be ready to buy heavy-duty rings if needed for secure suspension. If you need flexibility, consider lightweight, portable units with handles so you can relocate them easily. A remote control option adds convenience, letting you adjust settings from across the shop without interrupting work.

Maintenance and Replacement

1 practical consideration you’ll want to factor into your choice of a shop air cleaner is how easy and costly ongoing maintenance will be, since regular filter care keeps the unit performing and your breathing zone safe. You’ll need to clean or replace filters periodically; some models let you blow dust out with compressed air, which cuts downtime. Replacement packs can vary in price—expect options around $65 for two—so check availability and size before buying. Technologies like ionization reduce clogging and can extend filter life two to three times, lowering how often you swap media. Choose units with simple, tool-free access so you can change filters quickly, and inspect filters visually: heavy dust buildup signals it’s time to act to maintain air quality.

Budget and Operating Costs

Having a handle on filter care and replacement routines also helps you plan the financial side of running a shop air cleaner, since maintenance habits directly affect what you’ll pay over time. Start by comparing initial purchase prices, then add projected filter costs—replacement packs can be about $65 for some models and rise with advanced media. Prefer units with extended filter lifespans; ionic or anti-clog designs can last two to three times longer, cutting annual spend. Include energy use in your budget: units engineered to reduce fan load save electricity while keeping airflow efficient. Factor noise ratings too, since quieter machines improve comfort during long sessions and reduce indirect costs. Finally, weigh warranty and support; longer coverage often protects you from unexpected repair bills.

FAQ

Do These Units Reduce Fine Particulate (Pm2.5) Effectively?

FAQ 1: Do air purification units reduce PM2.5 levels?

Yes, air purification units can significantly reduce PM2.5 levels when equipped with true HEPA or high-efficiency filters.

FAQ 2: How effective are these units in reducing PM2.5?

When properly selected and maintained, these units can lower PM2.5 levels by 70–95%.

FAQ 3: What airflow settings should I use for optimal PM2.5 reduction?

It’s important to run the units at adequate airflow to achieve the best results in PM2.5 reduction.

FAQ 4: How do I choose the right unit for my shop?

Select a unit that is rated for your shop’s volume to ensure effective air purification.

FAQ 5: Where should I position the air purification unit?

Position the unit to pull air across your work area for maximum effectiveness in reducing PM2.5.

FAQ 6: Should I run the units continuously?

Yes, running the units continuously during dusty tasks helps maintain lower PM2.5 levels.

FAQ 7: How often do I need to replace filters?

Filters need regular replacement to ensure continued effectiveness in capturing fine particulate matter.

FAQ 8: What is the role of prefilters in air purification?

Prefilters help capture larger debris, which can enhance the performance and lifespan of the main filters.

FAQ 9: Does the measurement of PM2.5 reduction vary?

Yes, the measured reduction can vary based on the specific unit and its maintenance.

FAQ 10: What types of filters are best for PM2.5 reduction?

True HEPA and high-efficiency filters are the most effective types for significantly reducing PM2.5 levels.

Can They Be Vented Outdoors Instead of Recirculating?

1. Can shop air cleaners be vented outdoors?

Yes, many shop air cleaners can be vented outdoors. However, you’ll need to choose a model that is designed for ducting or modify an existing unit.

2. What type of units are best for outdoor venting?

Convertible units or dedicated exhaust fans are ideal for venting outdoors. These types are specifically designed to handle external duct losses effectively.

3. Are sealed recirculating filters suitable for outdoor venting?

No, sealed recirculating filters are not suitable for outdoor venting as they are not designed to manage external duct losses.

4. What should I consider when planning duct size?

It’s important to plan the duct size carefully to ensure proper airflow. A well-sized duct will improve the efficiency of the system.

5. How can I prevent backdraft when venting outdoors?

Incorporating backdraft prevention mechanisms is crucial to avoid air from flowing back into the shop. This can be achieved through the use of backdraft dampers.

6. Where should I place the outdoor vent?

Proper placement is essential to prevent dust from being directed into neighboring areas. Aim to position the vent away from common pathways and adjacent properties.

7. Do I need to follow any guidelines for outdoor venting?

Yes, you should follow the manufacturer’s guidance and local building codes when venting outdoors. Compliance ensures safety and efficiency.

8. Will venting outdoors improve air quality?

Venting outdoors can enhance air quality by removing particles more effectively. This leads to fresher air in your workspace.

9. Can I modify my existing air cleaner for outdoor venting?

Modification is possible, but it requires careful planning and knowledge of the unit’s capabilities. Ensure that any modifications maintain the system’s effectiveness.

10. What are the benefits of venting air cleaners outdoors?

Venting outdoors provides better particle removal and a fresher atmosphere in your shop. It can also reduce the accumulation of dust and allergens indoors.

Are Replacement Filters Widely Available and Affordable?

1. Are replacement filters easy to find?

Yes, replacement filters are widely available from both manufacturers and third-party brands. You can find them online and at home improvement stores.

2. Are replacement filters affordable?

Generally, replacement filters are budget-friendly. Basic HEPA or prefilter combinations are typically priced lower, while specialty or OEM filters can be more expensive.

3. What types of filters are commonly available?

Common filter types include HEPA and prefilters, available in various sizes and cartridge types. This variety ensures compatibility with many air purifiers and HVAC systems.

4. Where can I purchase replacement filters?

You can purchase replacement filters from online retailers and local home centers. Many stores carry a selection of common sizes for easy access.

5. How do prices for filters vary?

Prices for replacement filters vary based on quality and filtration level. Basic filters are usually more affordable, while high-performance or specialty filters may cost more.

6. Should I keep a spare filter on hand?

Yes, it’s advisable to keep a spare filter on hand. Having an extra ensures you can easily replace it when needed, maintaining optimal air quality.

7. How often should I replace my filters?

Follow the manufacturer’s recommended replacement intervals to ensure effectiveness. Regular replacement is key to maintaining good air quality.

8. Can I compare different filters before buying?

Absolutely! Comparing specifications helps you find a filter that balances performance and cost, ensuring you choose the best option for your needs.

9. Are there different filtration levels available?

Yes, filters come in various filtration levels, ranging from basic to specialized options. Selecting the right level depends on your specific air quality needs.

10. Do third-party filters work as well as OEM filters?

Many third-party filters are designed to meet or exceed performance standards of OEM filters. However, it’s important to check reviews and specifications to ensure quality.

Do These Systems Work in Garages With High Humidity?

1. Can air filtration units operate in high-humidity garages?

Yes, many tabletop and ceiling air filtration units can function in high-humidity garages, but precautions are necessary.

2. What type of housing should I look for in air filtration units for humid conditions?

Choose models with corrosion-resistant housings to ensure durability and performance in humid environments.

3. How often should I replace filters in high-humidity environments?

Filters should be replaced more frequently in high-humidity settings, as moisture can clog the filtration media.

4. Are there air filtration units that should be avoided in humid garages?

Yes, avoid units that are designed for dry-only operation, as they may not perform well in high-humidity conditions.

5. Is it advisable to use a dehumidifier alongside air filtration units?

Running a dehumidifier when possible is recommended to help maintain effective air filtration in humid garages.

6. Where should I mount the air filtration unit in a humid garage?

Mount the unit in a location that avoids direct condensation to prevent moisture-related issues.

7. How can I monitor the performance of air filtration units in humid conditions?

Regularly check the unit’s performance and filter condition to ensure it remains effective in humid environments.

8. What happens if moisture gets into the motor of an air filtration unit?

Moisture can potentially damage the motor, so choosing sealed motor units can help mitigate this risk.

9. Are there specific air filtration models recommended for garages?

Look for models specifically designed for garage use that mention suitability for high-humidity conditions.

10. What should I do if my air filtration unit isn’t performing well in humidity?

If performance declines, check for clogged filters, ensure proper mounting away from condensation, and consider using a dehumidifier.

Can Multiple Units Be Linked for Larger Workshops?

1. Can I link multiple units for larger workshops?

Yes, you can link multiple units to create larger workshops, enhancing coverage and Clean Air Delivery Rate (CADR).

2. Do I need matching models when linking units?

It is advisable to use matching models or units with compatible controls to ensure consistent airflow and filtration stages.

3. How should I position the units?

Position units to promote cross-flow and avoid creating dead zones, ensuring effective air circulation throughout the workshop.

4. What should I check regarding electrical load?

Always consult the manufacturer’s guidance on parallel operation and electrical load requirements to prevent overload and ensure safe operation.

5. Is zoning necessary when linking units?

Zoning with timers or speed controls can help balance noise levels and improve efficiency across the linked units.

6. How can I maintain performance reliability?

Regular maintenance and proper placement of the units are crucial for maintaining reliable performance and optimal operation.

7. What is CADR, and why is it important?

CADR stands for Clean Air Delivery Rate, which measures the efficiency of air purifiers. Higher CADR values indicate better air quality improvement in larger spaces.

8. Can I use units with different filtration technologies?

Using units with different filtration technologies may result in inconsistent performance; it’s best to use similar technologies for optimal results.

9. What are the benefits of linking multiple units?

Linking multiple units can lead to improved air quality, better coverage in larger areas, and increased overall system efficiency.

10. How do I ensure consistent airflow when linking units?

Ensuring consistent airflow involves placing the units strategically and using matching models to maintain similar airflow characteristics.

Final Thoughts

You’ve seen three practical options that balance power, price, and upkeep: the Abestorm for strong coverage, the WEN for quiet, budget-friendly use, and the AlorAir for larger shops needing maximum airflow. Choose based on workshop size, filtration efficiency, noise tolerance, and maintenance ease, and you’ll reduce airborne dust, protect your health, and extend tool life. With the right unit and basic upkeep, you’ll keep your shop cleaner and safer without overspending.