Are you a beginner woodworker looking to enhance your skills with the right tools? Choosing the right benchtop planer can be a game-changer in your woodworking journey, offering precision, ease of use, and affordability.

In this guide, we’ve handpicked three of the best models on the market: the DEWALT DW734, the VEVOR 13-inch two-blade, and the Cutech 40800H. Each of these planers excels in delivering high-quality finishes while addressing common challenges like snipe and tearout.

When selecting a benchtop planer, it’s essential to prioritize forgiving operation, accuracy, and budget-friendly options that allow you to learn without unnecessary frustration. These tools are designed with beginner woodworkers in mind, ensuring you can achieve great results right from the start.

In this roundup, we’ll break down what makes each model a standout choice and highlight key features to consider when making your decision.

Whether you’re tackling your first project or looking to refine your skills, these planers will help you achieve professional-looking results with ease.

Ready to find the perfect benchtop planer for your woodworking endeavors? Let’s dive into our top picks!

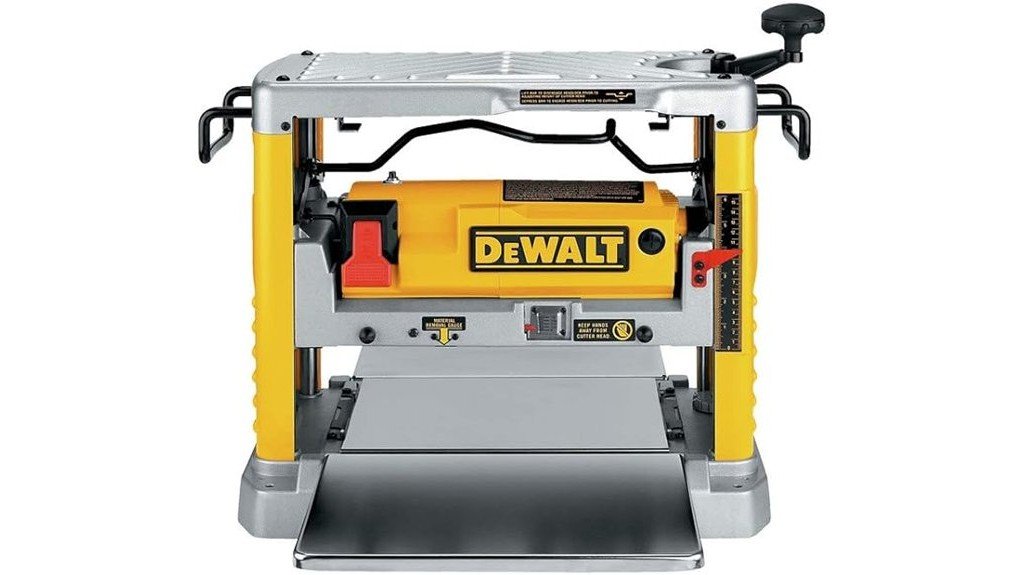

DEWALT Benchtop Planer, 12-1/2-Inch (DW734)

If you’re a beginner woodworker looking for a reliable, heavy-duty benchtop planer that handles larger stock without fuss, the DEWALT DW734 is a strong contender: its 15-amp motor and 12-1/2-inch cutting width let you tackle wide boards and hardwoods while the three-knife cutter head and 96 cuts per inch deliver a surprisingly smooth finish that reduces sanding time. You’ll appreciate durable, reversible knives for longer life, extra-long infeed/outfeed tables, and a four-column carriage lock that cuts snipe. Setup is quick, dust collection works well with a shop vac, and users report high satisfaction despite minor height-gauge limitations.

Best For: Beginner to intermediate woodworkers who need a reliable benchtop planer that handles wide hardwood boards and delivers smooth finishes with minimal fuss.

Pros:

- Powerful 15‑amp motor and 12-1/2″ cutting width for handling larger, thicker stock and hardwoods.

- Three-knife cutter head with 96 cuts per inch and reversible disposable knives for smooth finish and longer blade life.

- Four-column carriage lock plus extra-long infeed/outfeed tables reduce snipe and improve stability during planing.

Cons:

- Height gauge and fixed stops lack precision compared with digital readouts or higher-end models.

- Infeed/outfeed tables do not fold, which can take up significant shop space.

- Emergency shut-off switch placement can be inconvenient during operation.

VEVOR 13-Inch Two-Blade Benchtop Thickness Planer (1800W, 23500 RPM)

Woodworkers who want a balance of power and precision will find the VEVOR 13-inch two-blade benchtop planer a strong contender, especially when you’re working on wider boards or tackling hardwoods. You’ll appreciate the 1800W motor and 23,500 RPM spindle speed, which drive two HSS blades at up to 16,000 cuts per minute for smooth, consistent stock removal. The 13-inch cutting width and dual-roller feeding system reduce vibration and snipe, while the large 28.2 x 13 worktable stabilizes long or warped boards. It weighs about 58 pounds, accepts 2- or 4-inch dust hoses, and carries solid customer ratings and a 30-day return option.

Best For: Woodworkers needing a compact yet powerful benchtop planer for wider boards and hardwoods who want a balance of precision, stability, and dust management.

Pros:

- Powerful 1800W motor with 23,500 RPM spindle and two HSS blades delivering up to 16,000 CPM for smooth, efficient stock removal.

- 13-inch cutting width and large 28.2 x 13 worktable with dual-roller feed reduce vibration and snipe, stabilizing long or warped boards.

- Accepts 2- or 4-inch dust hoses to keep the workspace cleaner and has a solid customer rating plus a 30-day return option.

Cons:

- At 57.76 pounds and aluminum construction, it may be less portable for frequent shop rearrangement or jobsite use.

- Maximum cutting depth of 0.13 inches (1/8 inch) may be limiting for users needing deeper single-pass removal.

- Limited to a two-blade cutterhead design, which can require more frequent blade changes or tuning compared with multi-blade systems.

Cutech 13-Inch Benchtop Planer (40800H)

The Cutech 40800H 13-inch benchtop planer is a strong pick for beginners who want professional-level finishes without a steep learning curve, thanks largely to its six-row spiral cutterhead with tungsten carbide inserts that delivers smooth, tearout-free results. You’ll appreciate the 2-speed feed (16 fpm) and 8-position depth stop for repeatable cuts, and the flip dust hood helps keep your workspace cleaner. Assembly is quick, and the snipe minimizer with four lead screws reduces end-piece damage. It handles hardwoods, cutting up to 0.25 inches, and users praise flat, sanding-free surfaces despite occasional quality-control issues.

Best For: Beginners and hobbyist woodworkers seeking professional-level, tearout-free surfaces from a compact benchtop planer with carbide inserts and easy setup.

Pros:

- Six-row spiral cutterhead with tungsten carbide inserts delivers smooth, sanding-free finishes and reduced noise.

- Integrated snipe minimizer (4 lead screws + patented coupling) and 8-position depth stop enable consistent, low-snipe results and repeatable cuts.

- 2-speed feed (16 fpm), flip dust hood, and quick assembly make it versatile and user-friendly for hardwoods and various projects.

Cons:

- Some reported quality-control issues and occasional broken parts on delivery.

- Limited maximum cut depth (0.25 in) may require multiple passes for thicker stock.

- Benchtop size/weight (75.8 lb) may be less stable or portable compared with larger floor models.

Factors to Consider When Choosing Bench Planers for Beginner Woodworkers

When you’re choosing a benchtop planer, consider the cutting capacity and maximum width so the machine will handle the stock sizes you plan to work with. Check motor power and cutterhead speed, and decide between spiral or straight-knife cutterheads based on the finish you want and how often you’ll sharpen or replace blades. Also think about ease of use—adjustments, feed controls, and clear markings—and dust collection options to keep your workspace cleaner and your lungs safer.

Cutting Capacity and Width

1 clear measurement you should check first is a benchtop planer’s cutting width, since it dictates the maximum board size you can feed through without ripping or making extra passes. Most benchtop models offer about 12-1/2 to 13 inches of width, which suits common hobby projects and dimensional lumber. A wider cutting capacity saves time and reduces the need for multiple passes when you tackle broader boards, improving workflow and accuracy. Also consider maximum cutting depth—typically around 0.13 inches—so you can remove significant material in a single pass for leveling rough stock. Finally, look for a robust feeding system to maintain control and minimize snipe on longer or warped boards; that feature often makes the difference in finish quality.

Motor Power and Speed

Because motor power and cutter speed determine how smoothly and quickly a benchtop planer removes material, you’ll want to evaluate both specs closely before you buy. Look at motor ratings in amps or watts: higher numbers typically mean the machine can handle tougher materials and larger cuts without bogging down, which matters when you work with dense hardwoods. Check RPM too, since faster cutter speeds — some models reach about 23,500 RPM — let you remove material quicker and often produce smoother finishes. Remember that layout choices, like dual-blade designs, can increase effective cutting speed and surface quality compared with single-blade units. By understanding how power and speed interact, you’ll pick a planer that matches your project needs for efficiency and consistent results.

Cutterhead Type Choice

Having looked at motor power and cutter speed, you’ll also want to pay close attention to the planer’s cutterhead type, since it has a major influence on surface quality, noise, and maintenance. Choose a spiral cutterhead if you want smoother cuts and lower noise; its many small inserts shear fibers cleanly and reduce tear-out. A three-knife cutterhead delivers more cuts per inch, producing finer finishes and often cutting down on sanding. Look for disposable, reversible knives too — they last longer (about 30% more) and are quicker to replace than traditional blades. Consider cutterhead RPM: higher speeds remove material faster but may raise noise. Finally, check the design for snipe-reduction features, such as extra support points or integrated minimizers, to guarantee consistent results.

Ease of Use

How quickly can you get a benchtop planer set up and producing clean boards? You want a machine with intuitive controls so you spend minutes, not hours, learning how it works. Look for disposable, reversible knives and quick-change systems; they simplify maintenance and keep cuts consistent without advanced skill. A built-in material removal gauge and an extra-large thickness scale make it easier to dial in precise passes, reducing guesswork and wasted stock. Minimal reported snipe and user-friendly feed speeds help you achieve professional finishes sooner, lowering frustration during first projects. Overall, prioritize straightforward operation, easy blade maintenance, and clear measurement aids so you can focus on woodworking technique instead of troubleshooting the tool.

Dust Collection Options

Many benchtop planers come with dust-collection features you’ll want to check before you buy, since effective extraction keeps your workspace cleaner and helps the machine perform reliably. Look for planers that accept standard hoses—usually 2-inch or 4-inch—so you can hook up a shop vacuum or dust collector without adapters. Built-in dust hoods or ports make connection easier and often improve chip evacuation, reducing airborne particles and improving visibility while you work. Good dust management also protects the cutterhead and blades from buildup that can impair performance and cause premature wear. Read customer feedback about dust performance; positive reviews often highlight how a solid extraction system made projects more pleasant and safer, especially in small or shared shops.

Accuracy and Snipe Control

Because precise thickness and consistent surface quality make the difference between a good project and a great one, accuracy and snipe control are two of the most important things you’ll check when shopping for a benchtop planer. You’ll want gauges and depth indicators that let you remove material precisely, and turret depth stops help you return to common settings fast without guesswork. The cutter head matters too: multi-knife or spiral inserts produce smoother cuts and can reduce snipe by evening out load on the knives. Look for robust setup features, such as four-column carriage locks, and longer infeed and outfeed tables to support boards and minimize entry or exit droop. Together, these elements give predictable, consistent results for beginners.

FAQ

Can I Use a Benchtop Planer on Reclaimed or Rough Lumber?

FAQ 1: Can I use a benchtop planer on reclaimed lumber?

Yes, a benchtop planer can be used on reclaimed lumber, but it requires careful inspection and preparation of the boards.

FAQ 2: What should I look for when preparing reclaimed lumber for planing?

Inspect for nails, screws, and heavy dirt, and check for deep cracks or twists that could interfere with the cutterhead.

FAQ 3: How can I remove contaminants from reclaimed lumber?

Before planing, remove any nails or screws and clean off any dirt or debris to prevent damage to the planer.

FAQ 4: What is the best approach to planing rough lumber?

For rough lumber, take light, gradual passes to minimize tear-out and feeding issues during the planing process.

FAQ 5: Should I joint or hand-plane edges before using the benchtop planer?

Yes, jointing or hand-planing the edges beforehand can lead to better results and smoother finishes.

FAQ 6: How do I prevent tear-out when using a benchtop planer?

To reduce the risk of tear-out, always take light passes and ensure the surface is clean and free of defects.

FAQ 7: What types of defects should I be concerned about in lumber?

Look out for deep cracks, warps, or twists, as these can cause the planer to stall or result in uneven surfaces.

FAQ 8: Is sanding necessary after using a benchtop planer?

Yes, sanding is recommended after planing to refine the surface and achieve a smooth finish.

FAQ 9: How can I avoid feeding issues with the planer?

Maintain a consistent feed rate and ensure the lumber is properly supported and aligned to prevent jamming or misfeeding.

FAQ 10: Can I use a benchtop planer on heavily weathered wood?

While it is possible, heavily weathered wood may require additional preparation, such as removing loose fibers or debris, to ensure optimal results.

How Loud Are Benchtop Planers During Extended Use?

FAQ on Benchtop Planers and Noise Levels

1. How loud are benchtop planers during use?

Benchtop planers typically produce noise levels ranging from 85 to 100 dB during extended use.

2. Is hearing protection necessary when using a benchtop planer?

Yes, due to the high noise levels, hearing protection is essential to prevent hearing damage.

3. What factors affect the noise produced by a benchtop planer?

Noise levels can vary based on motor size, cutterhead speed, and the hardness of the wood being processed.

4. Do different types of wood affect noise levels?

Yes, denser or knotty boards can increase both sound and vibration during operation.

5. How does noise impact user fatigue?

Working in a noisy environment can lead to quicker fatigue, making it advisable to plan shorter work sessions.

6. What can be done to mitigate noise while using a planer?

Using barriers to dampen sound can help reduce noise levels in the workspace.

7. Does regular maintenance affect noise levels?

Absolutely, regular maintenance such as keeping blades tight and the cutterhead balanced can significantly reduce noise.

8. How can a user improve comfort while using a benchtop planer?

Maintaining the equipment properly not only reduces noise but also enhances overall comfort during use.

9. Are there any recommended practices for dust collection?

Good dust collection systems are recommended to maintain a cleaner workspace, which also contributes to a more comfortable environment.

10. What should I consider when planning work sessions with a benchtop planer?

Consider scheduling shorter work sessions to minimize fatigue and using sound-dampening strategies to enhance comfort during operation.

Do Planers Require Special Blades or Accessories?

1. Do planers require specific blades?

Yes, planers need blades that are specifically sized for your machine model. It’s essential to use the correct cutter head knives to ensure proper function.

2. How often should planer blades be replaced?

Blades should be replaced or rotated when they become dull. Regular maintenance of the blades will ensure optimal performance and finish quality.

3. What materials are planer blades made of?

Many planers accept blades made of carbide or high-speed steel. These materials offer longer life and better durability compared to standard steel blades.

4. Are there any accessories needed for planers?

Yes, several accessories can enhance the use of a planer, including push sticks, infeed and outfeed supports, and dust collection adapters. These tools help improve safety and efficiency during operation.

5. Do all planer brands use the same knife sets?

No, some brands require proprietary knife sets or specific accessories, which means you should verify compatibility with your model. Always consult your user manual for the correct parts.

6. What is the purpose of a push stick with a planer?

A push stick helps keep your hands safely away from the cutting area while guiding the wood through the planer. It’s an important safety accessory.

7. What is the benefit of using infeed and outfeed supports?

Infeed and outfeed supports provide stability for the wood as it enters and exits the planer, helping to prevent snags or uneven cuts. This ensures a smoother and safer operation.

8. Are dust collection adapters necessary for planers?

Yes, dust collection adapters are recommended as they help manage the wood shavings produced during planing. This keeps your workspace cleaner and safer.

9. Can I use any type of blade in my planer?

No, you should only use blades that are compatible with your specific planer model. Using incorrect blades can damage the machine and affect your work quality.

10. How can I determine the correct parts for my planer?

The best way to determine the correct parts is by checking your planer’s user manual. It will provide information on required blades, accessories, and safe operating procedures.

What Safety Gear Is Essential When Operating a Planer?

FAQ 1: What eye protection is recommended when using a planer?

It is essential to wear safety goggles or glasses that meet ANSI standards to protect your eyes from flying wood chips and dust generated during operation.

FAQ 2: Why is hearing protection necessary when operating a planer?

Planers can produce high noise levels that may lead to hearing damage over prolonged exposure, so using earplugs or earmuffs is crucial to safeguard your hearing.

FAQ 3: Should I wear a dust mask or respirator while using a planer?

Yes, a dust mask or respirator is advisable to protect your lungs from fine dust particles that can be harmful when inhaled during planing operations.

FAQ 4: What type of clothing is recommended when using a planer?

Wear snug-fitting clothing to prevent it from getting caught in the machine, and avoid wearing any loose items such as jewelry that could pose a safety risk.

FAQ 5: How can I keep my hands safe while using a planer?

Use push sticks or push blocks to keep your hands at a safe distance from the cutting area, reducing the risk of injury.

FAQ 6: What type of footwear is suitable when operating a planer?

It is best to wear steel-toe or sturdy closed-toe shoes to protect your feet from potential injuries caused by dropped workpieces.

FAQ 7: What precautions should be taken for long hair when using a planer?

If you have long hair, make sure to tie it back securely to prevent it from becoming entangled in the machinery.

FAQ 8: Are there any additional safety gear recommendations for vibration sensitivity?

If you are sensitive to vibration, consider wearing anti-vibration gloves to reduce the impact on your hands while operating the planer.

FAQ 9: What should I do before changing blades on a planer?

Always disconnect the power source before changing blades or clearing any jams to ensure your safety while performing maintenance.

FAQ 10: Why is it important to maintain a clean workspace when using a planer?

Keeping the workspace clean helps prevent slips and falls, and it minimizes the risk of fire hazards due to accumulated dust and debris.

Can I Plane Hardwoods Without Overloading the Motor?

1. Can I plane hardwoods without damaging the motor?

Yes, you can plane hardwoods safely by following proper techniques to avoid overloading the motor.

2. What steps can I take to prevent motor overload while planing?

Feed the wood in thin, consistent passes and avoid taking off too much material at once to reduce strain on the motor.

3. How important is blade sharpness when planing hardwoods?

Keeping the blade sharp is crucial, as a dull blade requires more power and can contribute to motor overload.

4. Should I adjust my feed rate for different types of hardwoods?

Yes, using a slower feed rate is advisable for exotic or wet hardwoods to maintain control and prevent stalling.

5. What happens if I try to remove too much material at once?

Removing excessive material can lead to motor strain, causing it to overload and potentially stall during operation.

6. How often should I clear chips while planing?

Frequent chip clearing is recommended to maintain optimal performance and prevent the motor from stalling.

7. Is it safe to use a planer on dense hardwoods?

Yes, but you must respect the wood’s stiffness and density by adjusting your feeding technique and blade sharpness.

8. What are the consequences of using a blunt blade on hardwoods?

A blunt blade forces the motor to work harder, increasing the risk of overheating and potential damage.

9. How do I know if I’m feeding the wood too quickly?

If you notice the motor struggling or hear unusual sounds, it’s a sign that you’re feeding too quickly and should slow down.

10. Can I plane wet hardwoods safely?

Planing wet hardwoods can be done, but it requires a slower feed rate and careful attention to blade sharpness to avoid stalling.

11. What benefits come from proper planing techniques?

Employing proper techniques leads to smoother finishes, safer operation, and a longer-lasting motor.

Final Thoughts

You’ve got three solid, beginner-friendly options: the DEWALT DW734 for power and smooth finish, the VEVOR for stability and reliable feeding, and the Cutech for tearout-free results with its spiral cutterhead. Pick based on budget, desired finish, and how often you’ll use it; factor in dust collection and ease of blade changes. With any of these planers you’ll get accurate, affordable performance that helps you build skill and confidence in your woodworking.