Are you a beginner woodworker looking to enhance your projects with the right tools? Choosing the right bench vise is crucial for ensuring your woodworking tasks are not only easier but also safer. A quality vise can significantly improve your ability to hold materials securely while you cut, shape, or assemble your workpieces.

In this guide, we’ll explore six excellent bench vises that cater specifically to novice woodworkers, balancing durability, ease of use, and affordability.

When selecting a bench vise, it’s important to consider a few key factors: the size of your workspace, your budget, and the types of woodworking joints and materials you’ll be handling. Whether you need a compact clamp-on model that saves space or a robust swivel vise for more demanding projects, there’s a perfect option out there for you.

Each vise we’ve included has been carefully chosen for its reliability and user-friendly features, making it easier for you to focus on your craft.

Ready to find the ideal bench vise that meets your woodworking needs? Keep reading to discover our top picks, complete with essential features and recommendations tailored just for beginners.

Scroll down to dive into the details and find the perfect fit for your workshop!

VEVOR 6-inch Bench Vise with 360° Swivel Base (Heavy Duty Ductile Iron)

If you’re a beginner who needs a sturdy, versatile vise that can handle a wide range of shop tasks, the VEVOR 6-inch Bench Vise is a strong choice: its forged 60,000 PSI ductile iron body and 20 kN (≈4,496 lb) clamping force give you the kind of durability and bite that’s rare at this price point. You’ll appreciate the 6-inch jaw width, 5.9-inch opening, 3.5-inch throat, and 360° swivel for flexible positioning. Replaceable serrated carbon-steel jaws, a 2.9×3-inch anvil, and magnetic jaw pads boost utility, while solid construction and high ratings make it ideal for DIY shops.

Best For: Beginners and DIYers who need a sturdy, versatile bench vise for general workshop tasks like drilling, cutting, grinding, and light pipe work.

Pros:

- Forged 60,000 PSI ductile iron body and up to 20 kN (≈4,496 lb) clamping force for strong, durable performance.

- 360° swivel base, replaceable serrated carbon-steel jaws, and 2.9×3-inch anvil for versatile clamping and positioning.

- High user ratings and solid value—sturdy construction and useful accessories (magnetic jaw pads, bolts, manual).

Cons:

- Included mounting bolts may be too short for thicker workbenches, requiring additional purchases.

- Some users report minor jaw misalignment out of the box.

- At 25 lbs, heavier than basic models and may be cumbersome to move or reposition frequently.

PONY Heavy Duty 5-inch Bench Vise with 360-Degree Swivel Base and Anvil

For beginners who want a durable, versatile vise without spending a fortune, the PONY Heavy Duty 5-inch Bench Vise stands out for its combination of clamp power and practical features. You’ll get 5-inch jaws, a 5-inch opening, and a 2-5/8-inch throat depth in a compact 16 x 8 x 9-inch cast iron body. The 360-degree swivel base and polished anvil make layout and metalwork easier, while replaceable hardened steel serrated jaws and permanent pipe jaws broaden your tasks. It delivers up to 5,512 lbs of clamping force, weighs 25.6 pounds, and earns high user ratings for value and safety.

Best For: Beginners and hobbyists seeking a durable, affordable bench vise with strong clamping power and versatile features for light-to-medium metalworking and woodworking tasks.

Pros:

- Solid 5-inch jaws with up to 5,512 lbs clamping force and replaceable hardened steel serrated jaws for reliable grip.

- 360-degree swivel base and polished anvil add versatility for layout, metalwork, and positioning.

- Integrated pipe jaws and durable cast iron construction offer multipurpose use and good value for the price.

Cons:

- Considered light-duty by some users; may not satisfy heavy industrial or professional shop needs.

- Fit and finish reflect its price point—surface imperfections and minor machining variances possible.

- At 25.6 lb, requires a sturdy bench for secure mounting and may be less portable.

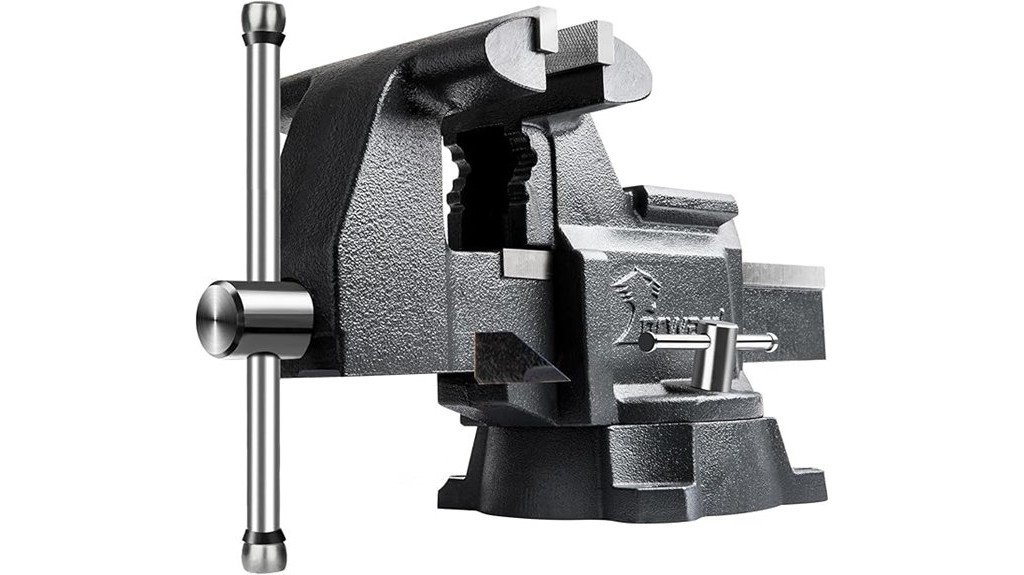

Forward CR40A 4.5 Inch Bench Vise Heavy Duty with Anvil and 210° Swivel Base

The Forward CR40A 4.5 Inch bench vise is a solid choice when you’re just getting started with woodworking and need professional-grade clamping without a steep learning curve; its 210° swivel base and 6600 lb clamping force give you the control to hold workpieces securely from multiple angles, making layout, sawing, and sanding easier. You get a durable ductile iron body, a 4.5-inch jaw width, and a 5-inch jaw opening that handle typical shop tasks. Built-in pipe jaws and replaceable serrated flat jaws add versatility, while the large anvil and solid lockdown deliver dependable performance for beginners and pros alike.

Best For: Beginners and professional DIYers who need a durable, versatile bench vise with strong clamping force and a 210° swivel base for general woodworking, metalworking, and pipe work.

Pros:

- Heavy-duty ductile iron construction with 6600 lb clamping force provides secure, professional-grade holding.

- 210° swivel base and large anvil increase versatility for layout, sawing, sanding, and angled work.

- Comes with replaceable serrated flat jaws and built-in pipe jaws (1/2″–3 1/2″) for multiple tasks.

Cons:

- Some users report rusting over time, so it may require more corrosion protection in humid environments.

- Requires regular lubrication to maintain smooth sliding and prevent stiffness.

- At about 19 lb, it may be heavier than lighter bench vises and could require a sturdy mounting surface.

WORKPRO Dual Jaws Table Vise (2.5″ & 1.5″) – 360° Swivel Clamp-On Mini Bench Vise for Woodworking & Metalworking

Compact yet surprisingly capable, the WORKPRO Dual Jaws Table Vise is an excellent choice for beginners who need a versatile, space-saving clamping solution for small woodworking and metalworking tasks. You’ll appreciate its dual-jaw design—2.5″ serrated and 1.5″ smooth jaws—so you can grip pipes, tubes, or delicate pieces without swapping tools. The 360° swivel gives full access to your workpiece, and clamp-on or bolt-down mounting fits most benches. Built from ductile iron with hardened carbon steel jaws and a galvanized handle, it delivers up to 660 lbs of clamping force. It’s compact, well-made, and ideal for hobby projects.

Best For: Compact workspace hobbyists and beginners needing a versatile, clamp-on mini bench vise for small woodworking, metalworking, and regripping tasks.

Pros:

- Dual jaws (2.5″ serrated + 1.5″ smooth) for gripping a wide range of materials without swapping tools.

- 360° swivel and clamp-on/bolt-down mounting provide flexible positioning and easy installation.

- Durable ductile iron body with hardened carbon steel jaws and up to 660 lbs clamping force for reliable performance.

Cons:

- Compact size may be too small for larger projects or heavy-duty shop use.

- Clamp jaw opening/shape may not fit all workbench edges for clamp-on mounting.

- 1/4-20 bolts for bolt-down installation are not included.

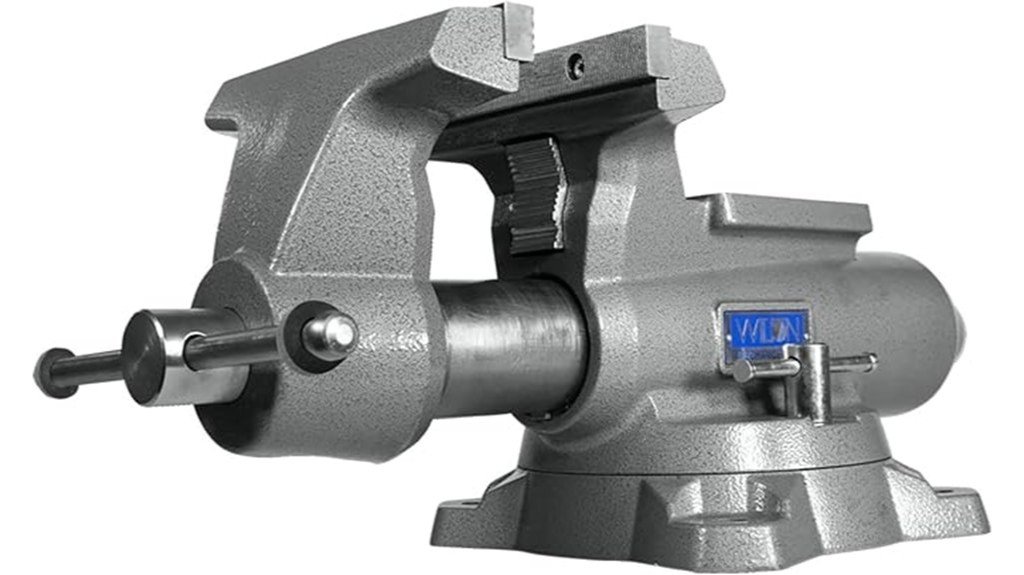

Wilton Mechanics Pro Bench Vise, 8″ Jaw Width (Model 880M)

If you want a vise that handles heavy-duty tasks without overwhelming a beginner, the Wilton Mechanics Pro 880M is a strong contender, offering an 8″ jaw width and a durable 60,000 psi ductile iron construction that’s built to last. You’ll appreciate the precision-machined slide bar that prevents front-jaw play, the needle-roller thrust bearing that boosts clamping force with less effort, and the enclosed spindle that keeps lubricants in and grit out. The 360° swivel base with double lockdowns and large anvil expand its versatility, while the lifetime warranty protects your investment despite occasional shipping or handling issues.

Best For: Durable, heavy‑duty bench vise needs for hobbyists and professionals who want strong clamping performance without an overly large industrial unit.

Pros:

- 8″ jaw width with 60,000 psi ductile iron construction delivers robust durability and long life.

- Precision‑machined slide bar, enclosed spindle, and needle‑roller thrust bearing reduce jaw play and make clamping smoother with less effort.

- 360° swivel base with double lockdowns and large anvil increase versatility for metalworking, welding, and blacksmithing tasks.

Cons:

- Some users report shipping and packaging damage on arrival (bent handles or minor assembly issues).

- At 83.1 pounds, it’s heavy and may be difficult to move or reposition without help.

- Higher initial cost and industrial build may be more than needed for very light, occasional home use.

IQ Vise 360° Articulating Bench Vise (Steel & Cast Aluminum, 8-Position Locking Ball & Socket)

For beginners who want maximum flexibility without a heavy industrial footprint, the IQ Vise 360° Articulating Bench Vise stands out with its full-range ball-and-socket articulation that lets you lock workpieces at virtually any angle. You get a hardened steel and cast aluminum body that’s durable yet reasonably lightweight at 10 pounds and compact dimensions for a crowded bench. Its Quick Cam and 8-position locking ball handle up to 130 ft‑lbs, while double-sided Flex-Fit jaws grip flat or round stock. It converts to pipe, wood, or bow vise, accepts accessories, and earns strong user ratings, though it’s not for heavy industrial tasks.

Best For: Beginners and hobbyists who need a lightweight, compact bench vise with full 360° articulation for flexible clamping of flat or round workpieces without industrial bulk.

Pros:

- Versatile 360° ball-and-socket articulation with Quick Cam and 8-position locks for precise angling and up to 130 ft‑lbs of torque.

- Durable yet relatively lightweight construction (hardened steel + cast aluminum, 10 lbs) that converts to pipe, wood, or bow vise and accepts accessories.

- Double-sided Flex-Fit jaws grip both flat and cylindrical stock; strong user ratings and broad accessory compatibility.

Cons:

- Not suitable for heavy-duty industrial tasks or very high clamping forces.

- Using soft or task-specific jaws can reduce the maximum jaw opening.

- Higher price point compared with basic bench vises (though buyers report good support and build quality).

Factors to Consider When Choosing Woodworking Bench Vises for Beginners

When you’re picking a bench vise, pay close attention to jaw width and maximum opening so it can securely hold the stock you work with, and don’t forget throat depth which determines how far from the edge you can clamp. Consider materials and build quality—cast iron or steel lasts longer under heavy use—and decide whether a swivel or fixed mounting better suits your bench layout and workflow. If you plan to work with piping or round stock, check for a pipe-jaw feature or compatible add-on to avoid slipping and protect the workpiece.

Jaw Width & Opening

Because the jaw width and opening determine what sizes and thicknesses you can clamp, you should pay close attention to these measurements when choosing a bench vise. Jaw width typically ranges from about 4.5 to 8 inches; narrower jaws suit small hobby pieces and detailed work, while wider jaws let you steady larger boards and assemblies. Jaw opening—the maximum gap between jaws—usually falls between roughly 5 and 8.5 inches, so check that it fits the material thicknesses you plan to use. Larger width and opening increase versatility, which is helpful as you try varied projects. Also match jaw faces to tasks: serrated or toothed faces grip flat stock, while smooth faces protect delicate pieces, letting you clamp without marring surfaces.

Throat Depth Importance

Think of throat depth as the invisible reach of your vise—the distance from the jaw opening’s center back into the body—which directly determines how much of a workpiece you can grip and how comfortably you can work on it. You’ll want to match throat depth to the size and thickness of projects you plan to tackle, since deeper throats let you clamp thicker materials or reach further into large pieces. Typical throat depths run about 2.5 to 4.5 inches, so choosing the right measure boosts versatility without overpaying for features you won’t use. Throat depth also affects stability and how easily you access the workface, influencing grip security when you saw, plane, or chisel. Pick a depth that fits your common tasks to avoid limits later.

Material & Durability

After you’ve considered throat depth and how it affects the parts of a project you can reach, the next thing to check is what the vise is made of and how long it’ll hold up under regular use. You’ll want ductile or cast iron for core components because those materials resist wear and handle heavy loads; ductile iron, for example, often offers tensile strength near 60,000 psi, so it won’t easily deform under pressure. Inspect the jaws: replaceable hardened steel jaws preserve grip and let you renew the contact surface without replacing the whole unit. A powder-coated finish helps prevent rust in damp shops, and heavier vises usually give more stability during demanding tasks. Choose materials that match the projects you plan to tackle.

Swivel Vs Fixed

When you’re choosing between a swivel and a fixed vise, weigh versatility against stability: swivel vises let you rotate a workpiece up to 360 degrees so you can approach it from different angles and clamp odd shapes more easily, while fixed vises hold a constant orientation that often gives better resistance to torque and vibration during heavy-duty or precision cuts. You’ll appreciate a swivel base when tackling varied projects because it lets you reposition stock without re-clamping, making complex setups faster and more flexible. Fixed vises, by contrast, offer predictable alignment and steadiness for tasks that demand consistent support. Check clamping force on any swivel model to verify it grips without slipping, and match your choice to the kinds of cuts and shapes you plan to do.

Pipe-Jaw Capability

If you plan to work with pipes or need a vise that handles rounded stock, pipe-jaw capability is a feature you’ll want to prioritize, because it directly affects how securely and safely you can grip cylindrical objects for drilling, cutting, or bending. You’ll appreciate vises with built-in pipe jaws that cover a wide diameter range—typically about 0.6 to 3.5 inches—since they let you clamp common sizes without extra adapters. Look for serrated or contoured faces that bite gently yet firmly, preserving the pipe’s surface while preventing slippage during forceful work. A wider, adjustable clamping range increases versatility and reduces tool swapping, speeding projects and lowering frustration. For pipe fitting and light metalwork, this capability makes a bench vise far more useful and efficient.

Mounting & Installation

Handling pipes well is only part of the story; how you mount your vise determines how reliably it performs across every task. When choosing, confirm whether the model is clamp-on or bolt-down and that it fits your bench without wobbling, since a secure attachment prevents frustrating movement. Check that the included mounting bolts match your bench thickness — some vises need longer bolts you’ll have to buy separately. Prefer vises with a swivel base if you want flexible positioning for varied work angles. Consider weight too: heavier vises usually resist shifting and feel steadier under load. Finally, verify the installation is straightforward and that the package includes all necessary components and a manual, so you can install with confidence and minimal fuss.

Budget & Warranty

A few dollars can make a big difference when choosing a bench vise, so plan your budget with both immediate cost and long-term value in mind: entry-level models start around $30, mid-range options commonly sit between $75–$150, and heavy-duty industrial vises can exceed $300, with higher prices often reflecting stronger materials and better build quality that reduce the need for replacement. Decide what tasks you’ll do and balance cost against durability; paying more upfront often saves money over years by avoiding replacements. Check warranties closely—look for coverage of manufacturing defects and extended or lifetime guarantees. Read customer reviews about warranty claims and service, and confirm a flexible return policy so you can test fit, function, and suitability without financial risk.

FAQ

How Do I Maintain and Lubricate a Bench Vise for Longevity?

FAQs on Maintaining and Lubricating a Bench Vise

1. How often should I clean my bench vise?

Regular cleaning is essential to maintain your bench vise. Aim to clean it every few weeks or after heavy usage to prevent debris buildup.

2. What tools do I need to clean my bench vise?

A brush and light solvent are ideal for removing chips and rust. Make sure to have a dry cloth on hand for thorough drying after cleaning.

3. What type of lubricant should I use for my bench vise?

Use light machine oil or white lithium grease for lubrication. These options provide effective protection without attracting excessive dirt.

4. How do I apply lubricant to my bench vise?

Apply the lubricant sparingly to the lead screw and guide rails. Open and close the vise several times to ensure even distribution.

5. Why is it important to inspect fasteners on my bench vise?

Inspecting fasteners ensures that all parts are secure and functioning properly. Tighten any loose components to maintain stability and performance.

6. Where should I store my bench vise?

Always store your bench vise in a dry location to prevent rust. Avoid areas with high humidity or exposure to moisture.

7. How can I prevent rust on my bench vise?

Occasional light sanding can help remove any surface rust without damaging the vise. Following this with a lubricant application will provide added protection.

8. What should I do if I notice rust on my bench vise?

Address any rust immediately by using a brush or sandpaper to remove it. After cleaning, reapply lubricant to protect against future rusting.

9. Can I use heavier grease for lubrication?

It’s best to avoid heavier grease as it can attract more debris and hinder smooth operation. Stick with light machine oil or white lithium grease for optimal performance.

10. Is it necessary to lubricate the jaws of the bench vise?

Lubricating the jaws is not typically necessary; focus on the lead screw and guide rails. However, ensure the jaws are clean and free from debris to maintain proper clamping action.

Can a Bench Vise Be Used for Delicate Wood Without Damaging It?

FAQ 1: Can a bench vise hold delicate wood without causing damage?

Yes, a bench vise can hold delicate wood, provided you take precautions to protect the material.

FAQ 2: What materials can I use to protect the vise jaws?

You can wrap the jaws with leather, soft wood pads, or rubberized covers to cushion the wood.

FAQ 3: Should I use scrap wood when clamping delicate pieces?

Yes, placing scrap wood between the vise and your workpiece helps prevent any marks or damage.

FAQ 4: How should I tighten the vise when working with delicate wood?

Tighten the vise slowly, feeling for movement, to ensure you don’t apply too much pressure.

FAQ 5: What is a torque-limited method for clamping?

A torque-limited method involves tightening the vise to a specific level of pressure to avoid overtightening.

FAQ 6: Why is it important to avoid overtightening?

Overtightening can cause indentations or breakage in delicate wood, compromising its integrity.

FAQ 7: How can I judge the grip of the vise?

Using a scrap clamp can help you gauge the appropriate grip pressure needed for your workpiece.

FAQ 8: Can I use the vise for all types of delicate wood?

While many types can be clamped, always assess the specific characteristics of the wood to determine the best approach.

FAQ 9: What should I do if I notice movement while tightening?

If you notice movement, stop tightening to prevent damage and reassess the pressure being applied.

FAQ 10: Is it necessary to use protective padding every time?

Using protective padding is highly recommended whenever working with delicate wood to ensure safety and prevent damage.

What Safety Gear Is Recommended When Using a Bench Vise?

1. What safety gear should I wear when using a bench vise?

You should wear safety glasses, sturdy gloves, and hearing protection. A dust mask is also recommended if you are sanding or cutting nearby.

2. What type of gloves should I use with a bench vise?

Choose gloves that provide protection but still allow for good dexterity to make necessary adjustments. Avoid gloves that are too bulky or restrictive.

3. Why should I avoid loose clothing or jewelry when using a bench vise?

Loose clothing or jewelry can get caught in the vise or other equipment, posing a risk of injury. It’s best to wear fitted clothing and remove any accessories.

4. What should I do with long hair while working with a bench vise?

Secure long hair to prevent it from getting caught in the vise or machinery. Use a hair tie or cap to keep it safely in place.

5. How can I protect delicate workpieces in a bench vise?

Use bench vise jaw pads to cushion and protect delicate materials from damage during clamping. This helps prevent scratches and dents.

6. How often should I inspect my bench vise?

Regularly inspect your bench vise for any signs of cracks, wear, or loose bolts. This preventative measure can help avoid equipment failure during use.

7. What should I do if I find a defect in my bench vise?

If you discover any defects, such as cracks or loose bolts, refrain from using the vise until it has been repaired or replaced. Safety should always come first.

8. Is hearing protection necessary when using a bench vise?

Yes, wearing hearing protection is advisable if you are working in a noisy environment or using power tools in conjunction with the vise.

9. When should I consider using a dust mask?

A dust mask should be worn if you are sanding, cutting, or working with materials that produce dust or debris, to protect your respiratory system.

10. How can I maintain a clear workspace when using a bench vise?

Keep your workspace organized and free from clutter to ensure safety and efficiency. Make sure tools and materials are stored away when not in use.

How Do I Mount a Vise to a Portable Workbench or Sled?

FAQs on Mounting a Vise to a Portable Workbench or Sled

1. How do I position the vise on the workbench?

Position the vise near the edge of the sled or portable bench to ensure adequate jaw clearance for your projects.

2. What tools do I need to mount the vise?

You will need a drill, appropriate drill bits, a wrench for tightening, and possibly a saw if adjustments to the bench are necessary.

3. What type of bolts should I use?

Use hardened bolts along with washers and locknuts to ensure a secure and durable attachment of the vise to the bench.

4. How can I reinforce the mounting area?

Place a metal or hardwood backing plate under the bench where the vise is mounted to distribute the load and prevent crushing.

5. How do I ensure the vise is level?

After bolting the vise in place, check its alignment and adjust with shims if necessary to ensure it is square to the bench.

6. What is the importance of torqueing the fasteners?

Properly torqueing the fasteners ensures that the vise remains securely attached during use, preventing any movement that could affect your work.

7. Should I check the alignment after mounting?

Yes, it’s important to recheck the alignment of the vise after torqueing to confirm it is still square and correctly positioned.

8. What if I need to move the vise later?

If you need to relocate the vise, simply unbolt it, adjust the position, and then follow the mounting steps again to secure it in the new location.

9. Can I mount the vise on any type of portable workbench?

As long as the workbench is sturdy and has enough thickness to accommodate the bolts, you can mount a vise on most portable workbenches.

10. What safety precautions should I take?

Always wear safety glasses when drilling and use gloves when handling sharp or heavy components to ensure personal safety during installation.

Are There Accessories to Convert a Vise for Pipe Work or Soft Jaws?

FAQs on Converting a Vise for Pipe Work and Soft Jaws

1. What are pipe-jaw inserts?

Pipe-jaw inserts are accessories that allow a vise to securely clamp round stock, making it easier to work with pipes.

2. Can I use soft jaws with my vise?

Yes, soft jaws can be attached to your vise to protect delicate workpieces from damage during clamping.

3. What materials are soft jaws made from?

Soft jaws are commonly made from leather, plastic, aluminum, or wood, offering various levels of protection for different materials.

4. Are there complete kits available for converting a vise?

Yes, some kits come with everything needed for conversion, including spacer plates, bolt-on jaw faces, and rubber liners.

5. How important is fit and alignment when using vise accessories?

Fit and alignment are crucial for even pressure distribution. Proper installation ensures effective clamping without damaging the workpiece.

6. Do I need to check the size of accessories for my vise?

Yes, it’s essential to choose accessories that are specifically sized for your vise model to ensure compatibility and optimal performance.

7. What should I do before using the converted vise?

Always check that the accessories are installed tightly and verify that there is even pressure across the workpiece before beginning your work.

8. Are there any specific brands recommended for vise accessories?

While many brands offer quality accessories, it’s advisable to look for reputable manufacturers that specialize in vise tools and components.

9. Can I use pipe jaws on any vise?

Not all vises are compatible with pipe jaws; ensure your vise design allows for the installation of these specific accessories.

10. What is the benefit of using rubber liners with soft jaws?

Rubber liners provide additional grip and protect sensitive surfaces from scratches, enhancing the functionality of soft jaws.

Final Thoughts

You’ll find a reliable bench vise transforms your beginner projects, so choose one that matches your typical workpiece size, material, and clamping needs. Prioritize solid construction, smooth swivel or articulation for positioning, and a jaw design that protects wood. For occasional heavy tasks, opt for larger, cast-iron models; for small, detailed work, clamp-on or dual-jaw vises excel. With the right balance of strength, versatility, and ease of use, you’ll build skills more efficiently and enjoy safer, cleaner results.