Are you a workshop enthusiast or a professional craftsman looking to breathe cleaner air while you work? If so, you know that maintaining a healthy environment is just as crucial as having the right tools.

Dust, allergens, and fumes can accumulate quickly, creating an unpleasant and potentially harmful workspace. The right air filtration unit can make all the difference, dramatically reducing airborne pollutants and ensuring you can focus on your craft.

When selecting the best air filtration units for your workshop, consider factors like airflow efficiency (measured in CFM), the effectiveness of the filters (HEPA or multi-stage options are ideal), and user-friendly features such as quiet operation and remote control.

These elements will help you find a unit that not only performs well but also fits seamlessly into your space—making your workshop a cleaner and more enjoyable place to be.

In this roundup, we’ve curated a list of the top five air filtration units that strike the perfect balance between performance, portability, and value.

With these options, you can tackle dust clouds before they become an issue, allowing you to work more comfortably and efficiently.

Ready to discover the best products for your workshop? Scroll down to explore our top picks!

Abestorm 270 Degree Air Filtration System (DecDust 1080IG)

If you run a woodworking shop, garage, or any workspace where fine dust and fumes build up, the Abestorm 270 Degree Air Filtration System (DecDust 1080IG) is a strong choice because it combines high airflow with ionic and electrostatic assistance to capture micron-sized particles that typical filters miss. You’ll appreciate the 1080 CFM vortex fan with two speeds for flexible control, MERV-11 filtration, and a built-in ionizer that reduces clogging and extends filter life two to three times. It’s compact at 22 lbs, offers wall or ceiling install options, remote control, easy filter changes, and noticeable odor reduction.

Best For: Those running woodworking shops, garages, or craft and renovation workspaces that need high-CFM dust removal and improved air quality for micron-sized particulates.

Pros:

- High 1080 CFM vortex fan with 2-speed control rapidly clears large volumes of dust and fumes.

- Built-in ionizer and MERV-11 filters with electrostatic assistance reduce filter clogging and extend filter life 2–3×.

- Compact (22 lbs), portable design with wall/ceiling mount options, remote control, and easy filter/dust bag replacement.

Cons:

- Replacement filters may be limited in availability and potentially costly.

- Ceiling installation may require additional heavy-duty mounting hardware for safety.

- Ionic/electrostatic systems can cause ozone concerns for very sensitive users (noted by some as a consideration).

Air Scrubber 3-Stage HEPA 750CFM Portable Negative Air Machine

For workshop owners and contractors who need reliable, high-capacity air cleaning during renovations or remediation, the Air Scrubber 3-Stage HEPA 750CFM Portable Negative Air Machine is a strong choice because it combines a true H13 HEPA stage that captures 99.97% of particles ≥0.3 microns with a MERV‑10 prefilter and activated carbon stage for smoke and odors. You’ll get at least 50% more CFM than many competitors, improving removal of sawdust, pollen, pet dander, and smoke. The durable rotomolded shell, foldable handle, lockable 360° wheels, and daisy‑chain capability to 2250 CFM make transport and scaling easy. Controls, timer, filter indicator, certifications, and warranties round out a professional, user-friendly package.

Best For: Workshop owners, contractors, and remediation professionals who need a high‑capacity, portable air cleaner with true H13 HEPA filtration and daisy‑chain capability for renovation, fire, or sewage jobs.

Pros:

- True H13 HEPA + MERV‑10 prefilter and activated carbon stage captures 99.97% of ≥0.3 µm particles while removing smoke and odors.

- High airflow (750 CFM, up to 2250 CFM when daisy‑chained) and durable rotomolded housing with foldable handle and 360° lockable wheels for easy transport and scaling.

- User-friendly controls, timer, filter indicator, ETL/CETL/EPA certifications, and robust warranty (10‑year housing, 1‑year parts/labor).

Cons:

- Coverage (~350 sq ft) may require multiple units for larger spaces, increasing cost and storage needs.

- HEPA and carbon filters will require periodic replacement, adding ongoing maintenance expense.

- Larger size and industrial design may be overkill or less aesthetic for light residential use.

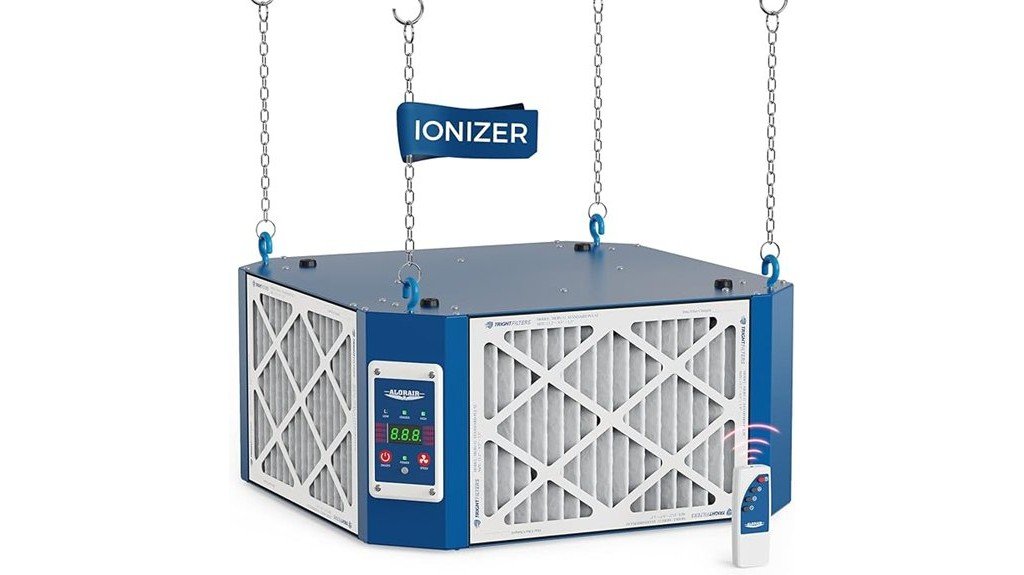

AlorAir 360° Intake Air Filtration System (1350 CFM) Purecare 1350IG

Woodworkers and hobbyists who work in spaces up to about 1,700 square feet will find the AlorAir Purecare 1350IG a strong contender, thanks to its 360-degree intake design and 1,350 CFM capacity that quickly captures sawdust and particulates from all directions. You’ll appreciate the compact iron housing (20.5 x 20.5 x 9.8 inches) and 27-pound weight that make mounting straightforward, while the two-speed vortex fan and Class MERV 11 filter stop most 1–10 µm particles. The built-in ionizer reduces odors, an IR remote and timer aid convenience, and users report clear air improvement though hardware upgrades may be wise.

Best For: Woodworkers and hobbyists with workshops up to 1,700 sq.ft who need a compact, high‑flow air cleaner to capture sawdust and fine particulates from all directions.

Pros:

- 360-degree intake with 1,350 CFM and strong two-speed vortex fan provides effective, high-circulation dust capture.

- MERV 11 filter plus built-in ionizer improves removal of 1–10 µm particles and helps reduce odors.

- Convenient features include timer (1–9 hours), IR remote control, and compact, mountable iron housing.

Cons:

- Filter efficiency (MERV 11) does not match HEPA for submicron particle removal.

- Included mounting hardware may be inadequate for heavier-duty installation — users often replace with stronger hardware.

- Relatively noisy (60–69 dB) and not available for shipping to California.

ALORAIR 2-Stage Air Filtration System (Purecare 780IG)

Hobbyists and small-shop professionals who need quiet, high-capacity dust control will appreciate the ALORAIR Purecare 780IG, a compact 2-stage unit that combines a robust vortex fan and a 270° intake to clear airborne sawdust across work areas up to about 800 sq. ft. You’ll get two-speed airflow (580/780 CFM), a Class MERV 11 filter that traps most 1–10 μm particles, and a built-in ionizer to reduce odors and fine pollutants. It runs under 50 dBA, includes an IR remote and timer, and can hang or sit on a bench; note filters can be hard to source and it won’t ship to California.

Best For: Hobbyists and small-shop professionals who need a quiet, high-capacity dust control solution for workspaces up to ~800 sq. ft., especially for woodworking tasks like sanding, carving, and rotary work.

Pros:

- Compact, lightweight design with 270° intake and strong vortex fan delivering 580/780 CFM for wide-area dust capture.

- Quiet operation (under 50 dBA), two-speed settings, IR remote, and programmable timer for convenient, low-noise use.

- Class MERV 11 filter and built-in ionizer effectively reduce 1–10 µm particles and odors common in woodshops.

Cons:

- Replacement filters can be difficult to find, causing maintenance hassles and potential downtime.

- Not available for shipment to California due to regulatory restrictions.

- Ionizer may produce ozone concerns for some users and isn’t a substitute for proper ventilation or PPE.

WEN 3410 3-Speed Remote-Controlled Air Filtration System (400 CFM)

If you work in a small shop or garage and want a compact, user-friendly system that actually reduces airborne dust, the WEN 3410 delivers with three adjustable speeds up to 400 CFM and a remote that operates from 26 feet away, so you can control air quality without interrupting your workflow. You’ll appreciate its 1/6 HP motor, lightweight 31-pound build, and coverage up to 400 sq ft; it runs quietly at 50–60 dB, mounts easily, and includes a programmable timer. Replaceable 1‑micron and 5‑micron filters keep performance high, maintenance stays simple, and a two‑year warranty adds confidence.

Best For: Small shop or garage owners who need a compact, easy-to-use air filtration system that reduces airborne dust during woodworking or light construction.

Pros:

- Three adjustable speeds up to 400 CFM with a remote (26 ft range) and programmable timer for convenient, flexible operation.

- Effective filtration with replaceable 1-micron and 5-micron filters, improving air quality for spaces up to 400 sq ft.

- Lightweight (31 lbs), quiet (50–60 dB), and easy to mount or move with included hardware and carrying handle.

Cons:

- Replacement filters can add ongoing cost (approx. $65 for two packs).

- Not ideal for very large industrial spaces beyond its 400 sq ft coverage.

- Some users may prefer higher CFM or more heavy-duty motors for extremely dusty, high-production environments.

Factors to Consider When Choosing Air Filtration Units for Workshops

When choosing an air filtration unit for your workshop, you’ll want to compare airflow capacity (CFM) to the size of the space so the unit can cycle air effectively. Look at the number and type of filtration stages and their efficiency ratings, since HEPA or carbon layers dramatically affect what contaminants are removed. Also consider noise level, and weigh installation options like ceiling mounts versus portable units to match your workflow and comfort.

Airflow Capacity (CFM)

One key specification you’ll see on any air filtration unit is its airflow capacity, measured in cubic feet per minute (CFM), and it tells you how much air the unit moves and filters over time. CFM directly affects how quickly a unit can clean the air in your workshop, so pick a model rated for your space — for many setups, a 400 CFM unit suits roughly 400 square feet. Look for units with adjustable CFM settings so you can ramp up airflow during heavy dust work and lower it for quieter, energy-saving operation. Keep in mind higher CFM often means more noise, so balance cleaning speed with acceptable sound levels. Also consider unit design, since efficient filters and airflow pathways can improve particle capture even at lower CFMs.

Filtration Stages

After you’ve matched airflow (CFM) to your shop size, the next thing to check is what happens to the air as it passes through the unit — the filtration stages determine which particles, gases, and odors get removed and how effectively. Look for multi-stage systems: a washable pre-filter grabs large dust and wood chips, extending service life. A HEPA or high-MERV stage captures fine particulates — a proper three-stage setup can trap up to 99.97% of particles down to 0.3 microns, which is ideal for dust and allergens. Activated carbon layers adsorb fumes and odors from solvents and finishes. Some units add ionizers to neutralize pollutants chemically, complementing mechanical filters. Match stages to your contaminants and maintenance preferences for the best workshop air.

Filter Efficiency Ratings

Because the number on a filter tells you how fine a unit can trap, paying attention to efficiency ratings is one of the smartest steps you can take when choosing an air filtration unit for your workshop. You’ll see MERV ratings commonly; higher numbers capture smaller particles, for example a MERV-11 catches most 3–10 µm particles and many around 1 µm. HEPA goes further, removing at least 99.97% of particles 0.3 µm and larger, which is ideal for fine dust and allergens. Consider units with multi-stage designs or built-in ionizers, since stages target different sizes and ionizers can boost capture by charging particles. Finally, keep filters clean and replace them on schedule, because clogged filters cut efficiency and raise energy use.

Noise Level (dB)

While you’re choosing an air filtration unit for your workshop, pay close attention to its noise level (measured in decibels), since sound can affect comfort, concentration, and fatigue over a long workday. Noise ratings vary widely: quiet models run below 50 dB and are well suited for woodworking, crafting, or shared spaces where focus matters. Units between 50–60 dB strike a practical balance, offering strong filtration while remaining relatively unobtrusive for most home and shop environments. Models above 60 dB deliver more power and may be appropriate for large or industrial spaces, but they can cause fatigue over long shifts. Check manufacturer decibel ratings at different fan speeds, match the unit to your sensitivity and workflow, and prioritize quieter operation if you spend hours nearby.

Installation Options

Choosing the right installation option for your workshop air filtration unit can make a big difference in performance and convenience, so think about where the unit will sit, how you’ll access it, and how it will interact with your workspace airflow. Many units let you wall-mount or suspend from the ceiling, which saves floor space and optimizes circulation patterns to capture dust where it rises. Portable models with sturdy handles and anti-slip grips give flexibility if you change layouts or need spot filtration. Look for built-in hooks, chains, or included hardware to simplify hanging, and consider heavy-duty mounts in high-dust or vibration-prone areas for long-term stability. Remote controls and intuitive panels let you tweak settings without climbing up to the unit.

Maintenance Requirements

Once you’ve settled on where the unit will sit or hang in your shop, you’ll want to plan for ongoing upkeep so the system keeps working at peak efficiency. Regular maintenance — mainly periodic filter replacement and cleaning — prevents clogging and preserves airflow, so you’ll get consistent dust capture and longer equipment life. Look for models with easy-to-replace filters; some let you swap cartridges quickly, reducing downtime and frustration. Note that filter lifespans vary: units with ionic technology can extend service intervals by roughly two to three times versus traditional designs, cutting trips to the supply store. Monitor indicator lights or perform visual checks routinely, and factor replacement costs into your budget — for example, some common two-packs run about $65.

Energy Consumption

Because energy costs add up over time, factoring power use into your selection will save you money and keep your shop running efficiently, especially if the unit will run for long periods. Look for energy-efficient designs that reduce fan load, such as electrostatic-assisted adsorption, since those technologies lower runtime power without sacrificing capture. Match CFM to room size: higher CFM cleans faster but usually draws more power, so balance capacity against actual needs. Choose units with multiple speed settings so you can cut energy use during light tasks and boost it for heavy dust production. Keep filters clean and replace them on schedule, because clogged filters force fans to work harder and raise consumption. For smaller or temporary spaces, compact units often offer good efficiency.

Portability and Size

Think about how and where you’ll move or store the unit, because portability and size directly affect how practical an air cleaner will be in your workshop. Weight matters: units typically range from about 22 to 31 pounds, so lighter models are easier to lift onto benches or carts, while heavier ones may need a dedicated spot. Compact designs—around 18 to 20 inches wide—fit tight corners and let you position filtration where it’s most effective. Look for built-in handles or wheels if you plan to shift the unit between work areas frequently. Ceiling-hang or wall-mount options free up floor space in cramped shops, and stacking-capable models simplify storage or transport when you control multiple units. Match size and mobility to your workflow for best results.

FAQ

Can These Units Remove Fumes From Solvent-Based Finishes?

FAQs on Removing Fumes from Solvent-Based Finishes

1. Can standard workshop air filtration units remove solvent fumes?

Standard workshop air filtration units primarily target dust and particulates, not solvent fumes.

2. What type of filters are needed to capture solvent vapors effectively?

Units equipped with activated carbon or specialty VOC filters are necessary to effectively capture solvent vapors.

3. What should I consider for strong or continuous use of solvent-based finishes?

For strong or continuous use, a dedicated fume extractor or enhanced ventilation through fresh air exchange is recommended.

4. How often should I change carbon cartridges in air filtration units?

Carbon cartridges should be changed regularly to maintain effective solvent vapor capture.

5. Are there specific filter specifications I should check?

Always check the filter specifications for VOC removal capabilities before making a purchase.

6. What safety precautions should I take when handling solvent-based finishes?

Follow safety data sheets and use personal protective equipment (PPE) to protect yourself while handling these finishes.

7. Is it sufficient to rely solely on air filtration for solvent fumes?

Relying solely on air filtration may not be sufficient; consider additional ventilation methods.

8. What are volatile organic compounds (VOCs)?

VOCs are chemicals that can easily evaporate at room temperature and are often found in solvent-based finishes.

9. Do all air filtration units capture VOCs?

Not all air filtration units capture VOCs; specialized filters are required for this purpose.

10. Can I use standard filters for solvent fumes?

No, standard filters are primarily designed for particulates and will not effectively remove solvent fumes.

How Often Should Pre-Filters Be Replaced in Heavy Dust Environments?

1. How often should I replace pre-filters in heavy dust environments?

Pre-filters should be replaced every 1–3 months in areas with heavy dust. It’s important to assess their condition monthly.

2. What signs indicate that a pre-filter needs to be replaced?

Look for visible dust buildup, reduced airflow, or increased blower noise. These are clear indicators that the pre-filter should be changed immediately.

3. Why is it important to replace pre-filters regularly?

Regular replacement protects the main filter and maintains overall system efficiency, ensuring optimal air quality and equipment performance.

4. What should I do if I notice significant dust accumulation on the pre-filter?

If you observe significant dust accumulation, replace the pre-filter right away to prevent strain on the main filter.

5. Should I keep spare pre-filters on hand?

Yes, it’s advisable to have spare pre-filters available. This allows for quick replacements when needed, ensuring continuous protection.

6. How can I track when to replace pre-filters?

Documenting the dates of replacements can help you establish a replacement schedule and monitor the condition of your pre-filters.

7. Are there specific times when I should replace pre-filters more frequently?

Yes, during peak sanding or cutting periods, consider shortening the replacement interval to maintain air quality and equipment efficiency.

8. What happens if I don’t replace the pre-filter when needed?

Failing to replace the pre-filter can lead to reduced airflow and increased strain on the main filter, potentially resulting in costly damages.

9. Can I clean and reuse a pre-filter instead of replacing it?

While some pre-filters can be cleaned, in heavy dust environments, replacement is generally more effective for maintaining airflow and filtration efficiency.

10. Is the replacement frequency the same for all pre-filters?

No, replacement frequency can vary based on the level of dust exposure. Adjustments may be necessary based on specific conditions in your environment.

Can Multiple Units Be Linked to Create Positive Pressurization?

FAQ 1: Can I link multiple air purification units for positive pressurization?

Yes, you can connect several units to achieve positive pressurization in a space.

FAQ 2: What is the first step to ensure effective positive pressurization?

Balancing airflow between the units is crucial for maintaining positive pressure without creating short-circuits.

FAQ 3: How do I calculate the clean air delivery rate (CADR)?

You need to determine the combined CADR of all units and compare it to the volume of the room to ensure adequate air supply.

FAQ 4: Where should I place the units for optimal air distribution?

Position the units strategically to supply fresh air throughout the room and avoid areas where the airflow may collide.

FAQ 5: Why is sealing important when creating positive pressurization?

Sealing gaps around doors and windows prevents air leakage, which is essential to maintain the desired pressure in the space.

FAQ 6: How can I equalize airflow between multiple units?

Utilizing variable-speed controls or dampers can help adjust and balance the airflow across your linked units.

FAQ 7: What should I monitor to ensure the system’s effectiveness?

Regularly check pressure differentials within the space to confirm that the positive pressurization is being maintained.

FAQ 8: How often should I maintain the filters in my units?

Filters should be maintained regularly to ensure optimal performance and efficiency of the air purification system.

FAQ 9: Can short-circuiting occur when linking multiple units?

Yes, short-circuiting can happen if the airflow paths are not properly managed, which is why strategic placement is important.

FAQ 10: What happens if the airflow is not balanced?

If airflow is not balanced, it can lead to ineffective air purification and potentially compromise the positive pressure effect you are trying to achieve.

Are These Units Compatible With Dust Collection Systems?

1. Are air filtration units compatible with dust collection systems?

Yes, many air filtration units can be integrated with dust collection systems, provided they meet specific criteria.

2. What factors determine compatibility?

Compatibility depends on airflow, duct size, and the type of connections used in the system.

3. Why is matching CFM ratings important?

Matching CFM ratings ensures that both the collector and filter work efficiently together, maintaining optimal performance.

4. What issues arise from using undersized ducts?

Undersized ducts can restrict airflow, leading to decreased performance of both the dust collector and the air filtration unit.

5. How can I secure connections between units?

Adapters or blast gates can be used to create secure and effective connections between the air filtration unit and the dust collection system.

6. Do air filtration units come with specific connection options?

Some air filtration units feature dedicated inlets or optional ports designed for direct hookup to dust collection systems.

7. How can I ensure efficient filtration?

It’s essential to consult the manufacturer’s specifications to confirm that the filtration unit will operate efficiently within the dust collection system.

8. What is the role of airflow in compatibility?

Proper airflow is crucial for ensuring that both the dust collection system and the air filtration unit function effectively together.

9. Can I modify my existing setup for compatibility?

Yes, modifications such as changing duct sizes or adding connection adapters may enhance compatibility between the units.

10. What should I consider before purchasing a unit?

Before purchasing, verify the CFM ratings, duct sizing, and compatibility features outlined in the manufacturer’s specifications.

Do These Filters Affect Room Humidity or Temperature?

FAQ 1: Do air filters affect room humidity?

No, air filters do not significantly alter room humidity levels. They are designed to circulate and capture particles but do not dehumidify the air.

FAQ 2: Can air filters change room temperature?

Air filters typically do not affect room temperature significantly. Their primary function is to clean the air rather than cool or heat it.

FAQ 3: What happens to airflow when air filters are used?

You may experience shifts in airflow when the units are running with air filters. This is due to the circulation of air as particles are captured.

FAQ 4: Is there warmth generated from air filters?

Localized warmth from motors can occur when using air filters, but it is usually minimal. The warmth is not enough to alter the overall room temperature.

FAQ 5: How do HVAC systems control climate?

HVAC systems are responsible for managing both temperature and humidity in a space. They work independently from air filters to maintain the desired climate.

FAQ 6: What should I use for humidity control?

For strict humidity control, consider integrating dehumidifiers or humidifiers into your system. These devices can help maintain desired humidity levels effectively.

FAQ 7: Can I rely on air filters for temperature regulation?

Air filters are not designed to regulate temperature. They are meant for improving air quality, so additional HVAC adjustments may be necessary for temperature control.

FAQ 8: Are air filters effective for air quality without affecting climate?

Yes, air filters effectively capture airborne particles and improve air quality without significantly influencing the climate of the room. Their main goal is filtration.

FAQ 9: Should I use additional equipment with air filters for climate control?

Yes, for optimal climate control, it’s advisable to use air filters alongside dehumidifiers, humidifiers, or HVAC adjustments. This combination helps maintain precise environmental conditions.

FAQ 10: How do I maintain precise environmental conditions?

To achieve precise environmental conditions, regularly monitor and adjust humidity and temperature settings. Integrate necessary equipment like dehumidifiers or HVAC systems with air filters for best results.

Final Thoughts

You’ll want one of these five units to cut dust, protect your lungs, and keep your workshop running cleaner and more efficiently. Consider room size, CFM, filter stages, noise, and maintenance cost so you match airflow and filtration to your projects. If you need portability or quiet operation, pick the WEN or Abestorm; for high CFM and heavy-duty jobs, choose the AlorAir or Air Scrubber. Regular filter changes will keep performance at its best.