Are you a woodworker in search of the perfect bench planer? Look no further! In this roundup, we’re showcasing the top five bench planers of 2026 that combine power, precision, and outstanding value.

Whether you’re tackling wide stock or aiming for fine finishes, these models are designed to elevate your woodworking projects and streamline your workflow.

When choosing a bench planer, it’s essential to consider key features such as high-torque motors, durable cutterheads, adjustable feed rates, and effective dust collection systems.

Each of the five models featured here excels in these areas, ensuring that you can achieve the desired results with ease and confidence.

With the right balance of capacity and cost, your woodworking shop will transform, allowing you to work more efficiently and effectively.

Ready to find the perfect bench planer to enhance your woodworking experience? Scroll down to explore our carefully selected product picks, complete with detailed comparisons to help you make an informed decision!

CRAFTSMAN 15 Amp Benchtop Planer (CMEW320)

If you need a portable benchtop planer that balances power with precision, the CRAFTSMAN 15 Amp (CMEW320) is a strong choice because its 15‑amp motor and two‑knife solid steel cutter head deliver the speed and durability required for both soft and hardwoods. You’ll appreciate 8,000 RPM cutter head speed producing 16,000 cuts per minute and a poly‑V drive that maximizes stock removal, while ball bearings guarantee smooth operation. At about 61 pounds it’s portable yet stable, with a 0.13‑inch cutting depth and reversible high‑carbon knives for long life. Expect straightforward setup, dust collection, and a three‑year warranty.

Best For: Woodworkers and DIYers who need a portable, powerful benchtop planer for dimensioning soft and hardwoods with reliable performance and easy setup.

Pros:

- Powerful 15‑amp motor with 8,000 RPM cutter head (16,000 cuts/min) for efficient stock removal.

- Two‑knife solid steel, reversible high‑carbon blades and ball‑bearing cutter head for durability and smooth operation.

- Portable yet stable (about 61 lbs) with dust collection port and straightforward setup; backed by a 3‑year warranty.

Cons:

- Can produce snipe at board ends if not carefully fed; requires technique or additional jigs to minimize.

- Blade wear on hardwoods — many users recommend keeping extra knives on hand.

- At 61 lbs, lighter than full‑size planers but still somewhat bulky for frequent transport.

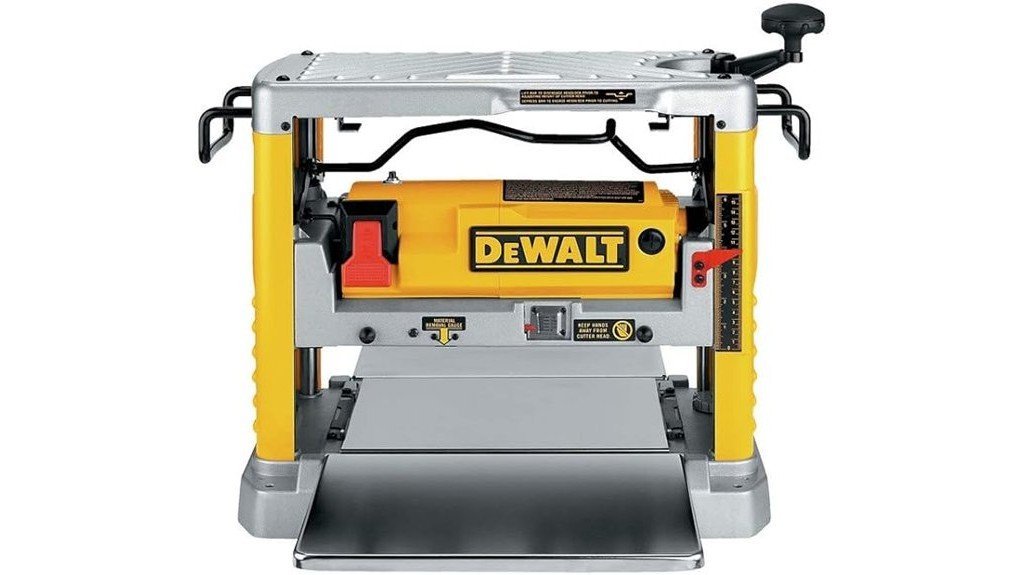

DEWALT Benchtop Planer 12-1/2-Inch (DW734)

Woodworkers who need a reliable, heavy-duty benchtop planer for frequent use will appreciate the DEWALT DW734, which pairs a powerful 15-amp motor and a 12-1/2-inch cutting width to handle wider boards and deeper cuts in hardwoods with ease. You’ll get a three-knife cutter head running at 10,000 RPM, delivering 96 cuts per inch for smooth finishes and disposable reversible knives that last longer. Extra-long infeed and outfeed tables, a four-column carriage lock to reduce snipe, and a turret depth stop enhance accuracy. Users praise quick setup, effective dust collection, and high satisfaction, though height gauge precision could improve.

Best For: Woodworkers who need a durable, high-performance benchtop planer for frequent use on wider boards and hardwoods.

Pros:

- Powerful 15-amp motor with a 12-1/2″ cutting width and three-knife cutter head for smooth, efficient material removal.

- Extra-long infeed/outfeed tables and four-column carriage lock reduce snipe and improve handling of longer stock.

- Disposable reversible knives and high user satisfaction with effective dust collection and quick setup.

Cons:

- Height gauge and fixed stops can lack precision for users needing very exact thickness control.

- Infeed and outfeed trays do not fold, which can take up valuable shop space.

- Emergency shut-off switch placement may be inconvenient during operation.

WEN PL1252 15-Amp 12.5-Inch Two-Blade Benchtop Thickness Planer , Black

The WEN PL1252 stands out as a solid choice for hobbyists and small-shop woodworkers who need a compact, powerful planer that handles boards up to 12.5 inches wide with reliable consistency. You’ll appreciate the 15A motor delivering 20,000 cuts per minute and a 26 fpm feed rate, which produce smooth surfaces quickly. Adjustable tables and return rollers help limit snipe and ease multiple passes, while two reversible SK5 blades extend cutting life. The cast-iron body feels stable, and a 2-inch dust port aids cleanup, though dust collection and noise draw occasional user criticism. Warranty and parts support are available.

Best For: hobbyists and small-shop woodworkers who need a compact, powerful benchtop planer for smoothing and thicknessing boards up to 12.5 inches wide.

Pros:

- 15A motor (20,000 cuts/min) and 26 fpm feed rate deliver smooth, efficient planing.

- Two reversible 12.5″ SK5 blades and cast-iron body provide durability and consistent results.

- Adjustable infeed/outfeed tables, return rollers, and a 2″ dust port improve usability and reduce snipe.

Cons:

- Dust collection effectiveness can be limited with the single 2″ port.

- Some users report relatively high noise levels during operation.

- Planing capacity limited to boards up to 6″ thick and 12.5″ wide, not suitable for larger stock.

VEVOR 13-Inch Two-Blade Benchtop Thickness Planer (1800W)

For hobbyists and small-shop professionals who need a sturdy, precise benchtop planer without taking up a ton of space, the VEVOR 13-inch two-blade thickness planer delivers a strong balance of power and control. You’ll appreciate its 1800W motor and 23,500 RPM capability, which drive two HSS blades at up to 16,000 cuts per minute for smooth hardwood passes. The 13-inch cutting width and 1/8-inch max depth let you dial in precise removal, while dual rollers reduce vibration and snipe. A large aluminum worktable stabilizes long boards, and dust ports accept 2- or 4-inch hoses for cleaner operation.

Best For: hobbyists and small-shop professionals who need a compact, powerful benchtop planer that balances precision and stability for hardwood and general woodworking tasks.

Pros:

- Powerful 1800W motor with up to 23,500 RPM driving two HSS blades for smooth, efficient hardwood planing.

- 13-inch cutting width and 1/8-inch max depth with dual-roller feed reduce vibration and snipe for controlled, professional finishes.

- Large aluminum worktable and compatibility with 2″ and 4″ dust hoses improve stability and dust management.

Cons:

- At 57.76 lbs and bench-mounted size, it may still be bulky for very small workspaces or frequent transport.

- Two-blade cutterhead may require more frequent sharpening or replacement than multi-blade systems for heavy continuous use.

- Warranty details are not included upfront (must check product link), and limited reviews (9) may provide less long-term reliability insight.

Cutech 13-Inch 2-Speed Benchtop Planer (40800H)

If you work with hardwoods or detailed figured wood and want smoother finishes with less sanding, the Cutech 13-Inch 40800H will likely be a great fit, thanks to its 6-row spiral cutterhead with tungsten carbide inserts that delivers quiet, tearout-resistant cuts. You’ll appreciate the 2-speed feed (16 fpm option) for handling tricky grain, the 8-position depth stop and clear depth indicator for consistent thickness, and the integrated snipe minimizer with four lead screws. Assembly is quick, dust management is practical via the flip hood, and user reviews praise the finish quality despite occasional shipping or QC issues.

Best For: woodworkers who need a compact benchtop planer that delivers smooth, tearout-resistant finishes on hardwoods and figured wood with minimal sanding.

Pros:

- Spiral cutterhead with tungsten carbide inserts provides quiet, smooth cuts and long-lasting edge life.

- Integrated snipe minimizer (4 lead screws + patented coupling) and 8-position depth stop give consistent thicknessing and reduced snipe.

- 2-speed feed (including 16 fpm) and flip dust hood improve handling of tricky grain and chip removal.

Cons:

- Some users report occasional shipping damage or broken parts, indicating quality-control risks.

- Benchtop size and 13″ width may limit capacity for larger stock or commercial-scale jobs.

- At 75.8 lbs and with a 10,000 RPM cutterhead, noise and vibration can still be noticeable compared with larger, heavier industrial planers.

Factors to Consider When Choosing Bench Planers for Woodworkers

When choosing a bench planer, you’ll want to weigh motor power and speed alongside cutterhead type to guarantee smooth, efficient stock removal for your projects. Consider cutting width and depth to match the size of workpieces you typically handle, while also checking build quality and weight for stability and portability. Don’t forget dust collection options, since effective chip management keeps your workspace cleaner and extends the machine’s life.

Motor Power and Speed

Because motor power and cutter speed determine how much wood you can remove and how smooth the finish will be, you’ll want to weigh both carefully before choosing a bench planer. A higher amperage motor, such as a 15 Amp unit, gives you the torque to tackle both soft and hardwood without bogging down, so you can take larger cuts confidently. Cutter head speed matters too: rates around 8,000 RPM or higher translate to many cuts per minute — for example, roughly 16,000 cuts per minute — which yields a finer surface. Motors with very high rotational speeds, like 20,000 RPM, remove material faster for demanding tasks, but require compatible design and blade setups. Ultimately, match motor power and speed to the density of wood and size of cuts you plan to make.

Cutterhead Type

Cutterhead type plays a central role in how your bench planer performs, so you’ll want to choose carefully based on the finish quality, noise level, and maintenance you expect; spiral cutterheads deliver smoother, quieter cuts and easier blade changes, while traditional straight-knife heads remain common on budget models and can still produce good results if you keep the knives sharp. You should weigh two-knife versus three-knife configurations: three knives give more cuts per inch, finer finishes, and longer time between sharpening. Higher cutterhead RPMs—around 20,000—yield more cuts per minute for faster, smoother stock removal. Look for reversible blades to double knife life, and consider cutterhead design details like ball bearings or dual rollers, which reduce vibration, boost stability, and minimize snipe for more accurate planing.

Cutting Width & Depth

While you pick a benchtop planer, pay careful attention to cutting width and depth since these specs directly determine what stock you’ll tackle and how many passes you’ll need; most benchtop models handle around 12.5–13 inches of width, which is fine for many common boards but limits you if you work with wider stock. The cutting width sets the maximum board size processed in one pass, so wider capacity reduces time and jointing complexity. Cutting depth, often adjustable up to about 0.13 inches per pass, controls how much material you remove and affects surface finish and tear-out. You’ll want a model that balances a generous width with reliable depth control, because greater capacity boosts efficiency and versatility across projects without forcing extra setup or multiple passes.

Build Quality & Weight

Build quality and weight play a big role in how a benchtop planer performs and how comfortable you’ll be using it day after day. Heavier models, typically between about 61 and 79.8 pounds (27.7–36.3 kg), offer greater stability during cutting, reducing chatter and helping you achieve smoother finishes. Look for bodies made from cast iron or aluminum, since those materials resist vibration and last longer under regular use. Robust designs often pair with solid steel or tungsten carbide knives, which extend cutting life and maintain edge quality. Consider dimensions too: compact planers are easier to transport and store if your shop is tight. Finally, a sturdy base with pre-drilled mounting holes improves stability and lowers the chance of snipe, an important practical benefit.

Dust Collection Options

Because dust quickly builds up and can obscure cuts, choosing a planer with good dust-collection options is one of the smartest decisions you can make for both safety and workflow. Look for dedicated dust ports that mate with standard shop vacuums or larger dust-collection systems; they cut airborne particles and keep chips from piling on your table. Consider port diameter—most range from 2 to 4 inches—and match it to your hose for ideal extraction. Some models include integrated vacuum ports designed to capture both sawdust and larger shavings during operation, which reduces cleanup and maintenance. Beyond health benefits, efficient dust removal improves visibility and tool longevity, letting you spend more time planning and less time clearing debris between passes.

Snipe Reduction Features

If you want consistently smooth, full-length boards, snipe reduction features deserve as much attention as motor size or cutter quality, since even minor end dips can ruin a project. Look for four-column carriage locks that stabilize the workpiece during planing; they secure the carriage and considerably reduce end lift. Some benchtop planers use integrated snipe minimizers with lead screws and coupling mechanisms, giving consistent thickness without extra locks. Adjustable infeed and outfeed tables add support as the board enters and exits the cutter, limiting snipe on longer boards. A depth stop lets you repeat exact cuts, helping maintain uniform ends. Finally, a well-designed feeding system—dual rollers, for example—reduces vibration and alignment drift, further minimizing snipe.

FAQ

Can These Planers Handle Reclaimed or Knotty Hardwood Safely?

1. Can bench planers handle reclaimed hardwood?

Yes, most quality bench planers can handle reclaimed hardwood, provided you take the necessary precautions to ensure safety and effectiveness.

2. What type of knives should I use for knotty wood?

Using sharp, robust knives is essential when planing knotty wood to reduce the risk of tear-out and ensure a smoother finish.

3. How should I set the depth-of-cut for knotty hardwood?

It’s advisable to reduce the depth-of-cut when working with knotty hardwood to minimize the chances of kickback and damage to the wood.

4. What feeding speed should I use for reclaimed wood?

Feeding the wood slowly through the planer will help prevent tear-out and ensure a more consistent finish, especially with reclaimed materials.

5. How do I prepare reclaimed wood before planing?

Inspect reclaimed wood for nails or metal and remove them before planing, as they can damage the blades and create safety hazards.

6. What should I do with warped boards?

Secure warped boards properly before planing to ensure they stay stable during the process, which can help achieve a better finish.

7. Are heavier-duty planers better for knotty wood?

Yes, heavier-duty models with higher horsepower and carbide knives are more capable of handling knots effectively without compromising performance.

8. How do machine settings affect planing reclaimed wood?

Choosing the appropriate machine settings, such as speed and depth, helps maintain control and reduces the risk of damage when planing reclaimed wood.

9. Do I need to wear protective gear while planing?

Yes, wearing protective gear like goggles and dust masks is important to keep safe from debris and dust generated during the planing process.

10. Can I support long pieces of wood while planing?

Yes, it’s beneficial to support long pieces of wood to prevent them from bending or dropping during planing, which can lead to uneven cuts.

What Maintenance Schedule Keeps Blades Sharp Longest?

FAQ 1: How often should I visually check my blades?

You should perform a visual check on your blades weekly to identify any immediate issues or signs of wear.

FAQ 2: What is the recommended cleaning schedule for blades?

Blades should be cleaned monthly to remove debris and prevent buildup that can affect their performance.

FAQ 3: How often should I hone my blades?

Light honing of blades should be done monthly to maintain their sharpness and ensure optimal cutting performance.

FAQ 4: When should I perform a full sharpening or knife rotation?

A complete sharpening or rotation of blades should take place quarterly, though this may vary based on usage levels.

FAQ 5: What should I do after a heavy or knotty job?

After such tasks, it’s essential to inspect your blades for any resin buildup or nicks and address these issues immediately to maintain their integrity.

FAQ 6: How can I keep my blades in good condition when not in use?

Blades should be kept dry and lightly oiled when stored to prevent rust and deterioration.

FAQ 7: What’s the best way to store blades?

Store blades safely in a designated area to avoid accidental damage or injury, ensuring they are protected from impacts.

FAQ 8: How do I track blade usage effectively?

Keep a log of hours used or jobs completed to monitor the lifespan of your blades and determine when they need replacing.

FAQ 9: When should I replace my blades?

Replace blades when you notice a significant drop in edge life or cutting performance, as this indicates they are no longer effective.

FAQ 10: What is regular dressing and why is it important?

Regular dressing with a fine stone or strop helps maintain a crisp edge on your blades, ensuring consistent cuts and prolonging their lifespan.

Are Replacement Parts Readily Available Internationally?

FAQs on International Availability of Replacement Parts

1. Are replacement parts available internationally?

Yes, replacement parts are generally available worldwide, but availability can differ based on brand and model.

2. What types of replacement parts are commonly found?

Common items such as knives, belts, and bearings are typically available from manufacturers, authorized dealers, and major online marketplaces.

3. What if I need niche components?

For niche components, you may need to contact a distributor or look into importing them, as they might not be readily available through standard channels.

4. How can I ensure I get the correct parts?

Before purchasing, check the warranty terms and part numbers specific to your equipment to avoid compatibility issues.

5. Where can I find regional service centers?

You can usually find regional service centers listed on the manufacturer’s website or by contacting customer service for assistance.

6. What should I consider when planning for overseas use?

If you plan to use equipment overseas, consider stocking critical spare parts to prevent downtime during important projects.

7. How can I confirm shipping times for replacement parts?

Check with the supplier or distributor about estimated shipping times to ensure you receive parts when needed.

8. Do warranty terms affect international purchases?

Yes, warranty terms can vary by region, so it’s important to review them before making an international purchase to understand your coverage.

9. Where can I buy replacement parts online?

Major online marketplaces and the manufacturer’s website are good places to start when looking for replacement parts.

10. Are all replacement parts easy to find?

Not all replacement parts are easy to find; common items are more accessible, while specialized components may require more effort to source.

How Noisy Are These Planers During Extended Use?

FAQs: Noise Levels of Planers During Extended Use

1. How loud are planers during extended use?

Planers typically operate between 85 to 100 dB, depending on the model and the load.

2. What factors increase the noise level of a planer?

Noise levels rise significantly when cutting hardwoods or making heavy passes.

3. Is hearing protection necessary when using a planer?

Yes, due to their loud operation, hearing protection is strongly recommended during extended use.

4. How does vibration affect the use of a planer?

Vibration can make the operation feel harsher over time, impacting user comfort during extended sessions.

5. Are there quieter options available for planers?

Yes, some models feature quieter motors and sound-dampening housings designed to reduce noise.

6. What additional features can help minimize noise exposure?

Optional dust enclosures can further help in reducing noise levels during operation.

7. How can regular maintenance affect the noise of a planer?

Regular maintenance helps keep noise levels down and ensures consistent performance during long sessions.

8. Do different planer models have varying noise levels?

Yes, different models can produce different noise levels, so it’s essential to check specifications.

9. Can noise levels impact the choice of planer for a user?

Absolutely, users concerned about noise should consider models specifically designed for quieter operation.

10. What should I consider before starting extended use of a planer?

Before extended use, ensure you have hearing protection, and consider the type of wood and passes you plan to make, as these factors influence noise levels.

Do Any Models Support Dust Collection Upgrades or Adapters?

1. Do bench planers support dust collection upgrades?

Yes, many bench planers are designed to accept dust collection upgrades or adapters.

2. What types of dust collection systems can be used with bench planers?

You can typically attach a shop vac or a 4″ hose to the chip port for effective dust collection.

3. How do I know if my bench planer can be upgraded for dust collection?

Check the port size and look for adapter availability specific to your model, as some manufacturers offer proprietary kits.

4. Are there standard fittings for dust collection on bench planers?

While some bench planers use standard fittings, others may require proprietary adapters from the manufacturer.

5. What benefits does upgrading to a dust collection system provide?

Upgrading improves dust control and air quality in your workspace, making it healthier to work in.

6. Does a dust collection upgrade help with cleanup?

Yes, effective dust collection significantly reduces the amount of sawdust and debris that needs to be cleaned up after use.

7. Will a dust collection upgrade affect cutter performance?

Yes, maintaining a cleaner work area helps preserve cutter performance by preventing dust buildup.

8. What should I consider before purchasing a dust collection upgrade?

Consider the compatibility of the upgrade with your specific planer model and the size of the port.

9. Can I use any shop vac with my bench planer?

Most bench planers can be paired with various shop vacs, but ensure the hose size matches the planer’s chip port.

10. Are dust collection upgrades worth it for occasional users?

While it’s especially beneficial for regular users, even occasional users can appreciate improved cleanliness and air quality.

Final Thoughts

You’ll find each of these five bench planers delivers the power, precision, and value woodworkers need, whether you’re tackling hobby projects or professional work. Consider motor amperage, cutterhead type, cutting width, dust collection, and build stability to match your workflow and material needs. Prioritize a smooth spiral cutterhead for fine finishes and higher amperage for resinous or hardwoods. With the right choice, you’ll get reliable results, cleaner shops, and faster, more confident project completion.