Are you working with limited space in your workshop and in need of a table saw that doesn’t compromise on power or precision? This guide is here for you!

We’ve curated a selection of the best table saws specifically designed for small shops in 2025. These models combine compact designs with robust features, ensuring you can tackle your woodworking projects without feeling cramped.

When choosing a table saw, it’s essential to consider factors like motor strength, rip capacity, and safety features. Our top picks include both portable 10″ and compact 8-1/4″ options, all equipped with powerful 15-amp motors and solid fences.

Additionally, we’ve prioritized user-friendly setups and storage solutions, so you can make the most of your workspace.

In this roundup, we’ll evaluate performance, dust control, and overall value, helping you find the perfect table saw that fits your needs and space.

Ready to discover the ideal tool for your next project? Let’s dive into our top product recommendations!

Bosch 10-Inch Portable Jobsite Table Saw (GTS15-10)

If you need a jobsite-ready table saw that balances portability with pro-level cutting power, the Bosch GTS15-10 is a strong choice: its 15-amp, 3,800-RPM motor and 10-inch, 50-tooth carbide blade deliver clean cuts while the gravity-rise wheeled stand lets you move and set it up quickly without a second person. You’ll appreciate the 32-1/8-inch rip capacity, single-cut 4×4 capability, and electronically regulated speed that holds RPM under load. Safety features include a smart guard system and convenience brake, while soft-start reduces breaker trips. At about 103 pounds, it’s durable, transportable, and well-reviewed.

Best For: Professionals and serious DIYers who need a portable, jobsite-ready table saw that balances pro-level cutting power with easy single-person setup and transport.

Pros:

- 15‑amp, 3,800 RPM motor with a 10″ 50‑tooth carbide blade delivers clean, consistent cuts and maintains speed under load.

- Gravity-rise wheeled stand with single‑action setup and 8″ treaded tires makes transport and setup quick and easy for one person.

- Safety and convenience features include the Smart Guard system, convenience brake (stops blade in ≈3 seconds), and soft‑start circuitry to reduce breaker trips.

Cons:

- At about 103 pounds, it’s portable for a jobsite but still relatively heavy to lift into trucks or tight spaces.

- Some users reported occasional minor alignment issues that may require calibration out of the box.

- A few customers experienced missing parts on delivery, requiring contact with customer service for replacement.

SKIL 15 Amp 10-Inch Portable Jobsite Table Saw (TS6307-00)

Designed for contractors and serious DIYers who need a portable yet precise saw, the SKIL 15-Amp 10″ Portable Jobsite Table Saw (TS6307-00) pairs a robust 15-amp motor with a 25-1/2″ rip capacity and rack-and-pinion fence system so you can rip full sheets or narrow ripped stock with confidence. You’ll appreciate the 10″ 24-tooth carbide blade, micro-adjustable parallel alignment, and 0–45° bevel with quick-release lever for accurate bevel cuts. The integrated folding stand and dust port elbow improve portability and cleanup, while anti-restart protection enhances safety. At about 51 pounds, it’s powerful, well-reviewed, and offers strong value for small shops.

Best For: Contractors and serious DIYers who need a portable, accurate jobsite table saw with a robust 15‑amp motor and good rip capacity.

Pros:

- Rack-and-pinion fence and micro-adjustable parallel alignment for accurate, repeatable cuts.

- Integrated folding stand and moderate 51 lb weight make it reasonably portable for jobsite use.

- Strong cutting performance (handles hardwoods) with useful safety features like anti-restart and dust port for cleanup.

Cons:

- Can be loud during operation.

- Users report occasional part failures (leg button, on/off switch) requiring replacement.

- Dust collection still leaves significant mess unless a shop vac is attached.

SKIL 15 Amp 8-1/4 Compact Portable Jobsite Table Saw (TS6308-00)

Think of the SKIL TS6308-00 as the go-to compact workhorse for hobbyists and small-shop owners who need serious cutting power without sacrificing portability: its 15-amp (1,800-watt) motor and 8-1/4-inch blade deliver a 2-1/2-inch maximum depth at 0 degrees and a roomy 24.5-inch rip capacity on the right, so you can rip plywood, cross-cut 2x4s, and tackle dadoes with confidence. You’ll appreciate the 39.8-pound aluminum table for stable, high-quality cuts, plus rack-and-pinion fence rails and micro-adjustment for precise alignment. Safety features include an immediate shutdown switch and anti-kickback pawl; a dust port improves cleanup. Practical, portable, and well reviewed.

Best For: Hobbyists and small-shop owners who need a portable yet powerful table saw for ripping plywood, cross-cutting 2x4s, and dado work.

Pros:

- 15 Amp (1,800 W) motor with 8-1/4″ blade offers strong cutting power and a 2-1/2″ max depth at 0°.

- Portable 39.8 lb aluminum table with rack-and-pinion fence and micro-adjustment for accurate, stable cuts.

- Good safety and cleanup features: immediate shutdown switch, anti-kickback pawl, and dust port for vacuum connection.

Cons:

- Some users report the saw can be noisy during operation.

- Blade elevation crank has occasional minor issues reported by customers.

- Stand (SFS0001) is sold separately, adding to overall cost for a full mobile setup.

15Amp Portable 10-inch Table Saw (Compact Benchtop, 36T Blade)

For hobbyists and small-shop owners who need a genuinely portable yet capable workhorse, the MarvTool 15Amp Portable 10-inch Table Saw delivers a strong balance of power and convenience. You’ll appreciate its 15‑amp motor spinning a 36T, 10‑inch blade at 4,600 RPM, letting you cut hardwoods, plywood, OSB, thin aluminum, and PVC with clean results. It’s lightweight at 28.3 pounds and compact for easy transport, yet it cuts up to 3.4 inches at 90° and 2.1 inches at 45°. The clear blade guard and dust port improve safety and cleanup, while included wrenches, push rod, and 24/7 support round out the package.

Best For: Hobbyists and small-shop owners who need a genuinely portable yet capable table saw for light-to-medium cutting tasks and easy transport.

Pros:

- Compact and lightweight (28.3 lbs) for easy transport and jobsite mobility.

- Powerful 15‑amp motor delivering 4,600 RPM with a 10″ 36T blade for clean cuts in hardwoods, plywood, OSB, thin aluminum, and PVC.

- Safety and cleanup features include a transparent blade guard and dust port; includes push rod and necessary wrenches plus 24/7 support.

Cons:

- Some users report motor reliability issues over time.

- Miter slots may be too small for some fences or accessories, limiting accuracy and compatibility.

- Stability can be lacking for larger or heavy-duty jobs, making an external stand or clamp-down necessary.

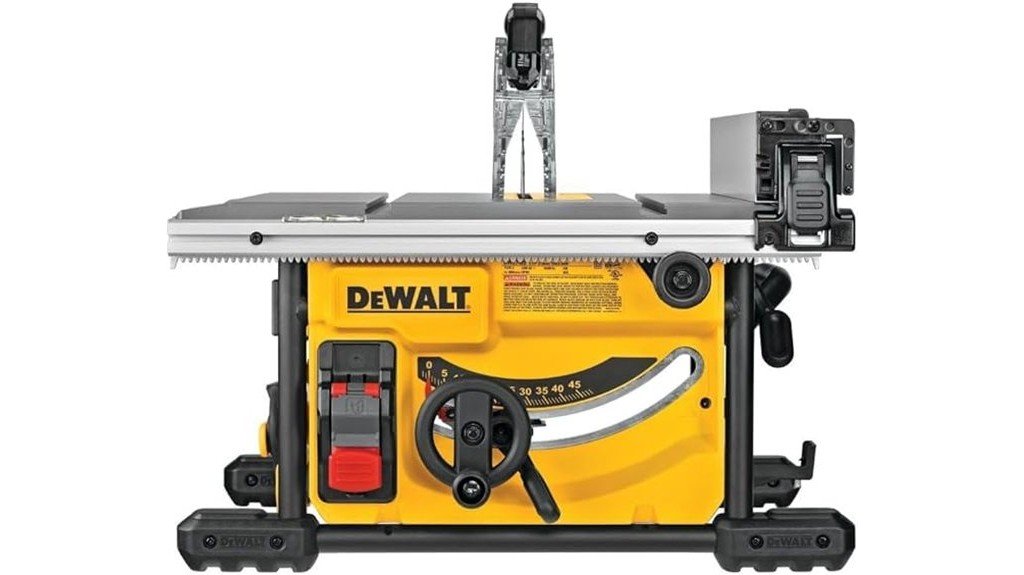

DEWALT 15 Amp 8-1/4 in. Compact Portable Jobsite Table Saw (DWE7485)

If you need a compact, jobsite-ready table saw that still handles full-sheet ripping, the DEWALT DWE7485 is a strong choice for small shops and mobile contractors alike: you get a 15 Amp, 5800 RPM motor in a 54-pound package that rips up to 24.5 inches, enough for 4×8 plywood. The rack-and-pinion fence and Site-Pro guarding system make adjustments fast and tool-free, while on-board storage and a metal roll-cage base boost durability and convenience. Users praise its power and portability, though some note miter gauge accuracy and missing vertical fence adjustment; it includes a power-loss reset and limited warranty.

Best For: Contractors and DIYers who need a portable, jobsite-ready table saw that can rip full 4×8 sheets while maintaining power and accuracy in a compact, transportable package.

Pros:

- 15 Amp, 5800 RPM motor with 24.5″ rip capacity handles full-sheet ripping (4×8 plywood) in a 54 lb portable unit.

- Rack-and-pinion telescoping fence and Site-Pro modular guarding system enable fast, smooth, tool-free adjustments and improved safety.

- On-board storage and a metal roll-cage base increase convenience and durability for jobsite use.

Cons:

- Miter gauge accuracy reported inconsistent by some users, may require purchase of an aftermarket gauge for precision work.

- No vertical fence adjustment, limiting fine-tuning for perfectly square cuts.

- Compact size limits some advanced features and may feel less stable than large stationary table saws for heavy-duty shop use.

Factors to Consider When Choosing Table Saws for Small Shops

When choosing a table saw for your small shop, you’ll want to weigh practical factors like space and footprint against the machine’s power and performance so it fits both your shop and your projects. Check built-in safety features, dust collection compatibility, and how easy the unit is to move or store, because those details affect daily workflow and long-term health. Balancing these elements will help you pick a saw that’s powerful enough for the work, safe to operate, and convenient to keep in a limited space.

Space and Footprint

Although your shop might be compact, choosing the right table saw can make the most of limited space by balancing size, mobility, and functionality. Measure the area where the saw will live, accounting for infeed and outfeed clearance; models span compact footprints around 25–30 inches up to much larger machines that dominate the floor. Weight matters — portable saws can be as light as 39.8 pounds, so you can move and stow them when needed. Seek integrated stands or folding legs to reduce stored footprint and speed setup. Match rip capacity to your typical projects; a smaller 24.5-inch rip is often enough for standard sheet goods and saves space. Finally, pick a layout that lets you handle material safely without crowding your workflow.

Power and Performance

Space and layout choices affect more than just where the saw will live; they also shape what level of power and performance you’ll need to get work done reliably. You want a motor—often 15 Amp—that sustains high RPMs (around 3,800–5,800) so cuts through hardwoods and plywood stay clean and efficient. Check rip capacity too; if you plan to process 4×8 sheets, a wider rip (up to about 32-1/8 inches) saves time and makes larger projects feasible. Look for electronically regulated speed and soft-start circuitry to keep power steady and reduce nuisance trips. Adjustable blade height and 0–45° bevels expand the range of cuts you can execute. Finally, effective dust ports that tie into a shop vac preserve visibility and keep your small shop cleaner.

Safety Features Included

Because table saws can throw serious hazards in a split second, you should prioritize machines with built‑in safety features that actively reduce the chance of injury and project damage. Look for a clear blade guard that shields your hands while still letting you see the cut line, and an adjustable riving knife paired with anti‑kickback pawls to keep material from pinching and launching back at you. An anti‑restart switch is essential; it prevents the saw from restarting after a power loss, which avoids unexpected spin‑ups. Immediate shutdown safety switches let you cut power fast in an emergency, giving you time to react. While not the focus here, a dust port that ties into a vacuum also helps by keeping the deck clear and reducing slip or trip risks.

Dust Collection Needs

Good dust collection can make a bigger difference in a small shop than you might expect, keeping the work area cleaner, safer, and healthier while also protecting your tools. You should prioritize models with integrated dust ports so you can hook up a shop vacuum quickly; that connection captures most airborne particles at the source and reduces respiratory risks. Look for a saw with a dust port elbow or similarly directed outlet, which funnels debris away from your face and workpiece, improving visibility and cut accuracy. Remember that poor dust control accelerates wear on motors and fences, increasing maintenance needs. Choosing a table saw with effective dust management saves cleanup time, preserves equipment performance, and keeps your shop a more comfortable place to work.

Portability and Storage

When your shop footprint is limited, choosing a table saw that’s easy to move and stow can transform how you work, so prioritize models with wheeled or folding stands and a compact footprint that won’t dominate the room. You’ll want a saw under about 30 inches in width and height when possible, since those dimensions let you tuck it against a wall or slide it under a workbench. Look for integrated folding stands and quick-release wheels so setup and takedown are fast, especially if you rearrange for different projects. Balance weight—many portables sit between 50 and 100 pounds—to keep the saw stable during cuts but still carryable. Finally, verify the saw has an effective dust port or elbow to keep a small shop clean and healthy.

FAQ

Can I Upgrade Blade Types for Different Materials on These Compact Saws?

FAQ 1: Can I upgrade the blade on a compact table saw?

Yes, most compact table saws allow for blade upgrades. This enhances cutting performance for various materials.

FAQ 2: What types of blades can I use with a compact table saw?

You can use blades designed for ripping, crosscutting, plywood, or nonferrous metals. Selecting the right blade type is essential for optimal results.

FAQ 3: How do I choose the right blade for my project?

Match the blade’s tooth count and hook angle to the specific cutting task. This ensures efficiency and clean cuts.

FAQ 4: Are there any safety features I should consider?

Always check for anti-kickback features and ensure proper guards are in place. These safety measures help prevent accidents during operation.

FAQ 5: What should I verify before changing the blade?

Check the arbor size and maximum RPM of your saw before installing a new blade. This ensures compatibility and safe operation.

FAQ 6: How do I improve accuracy when using a new blade?

Adjust the fence and blade height after installing the new blade. This is crucial for achieving precise cuts and maintaining safety.

FAQ 7: What material should I look for in replacement blades?

Quality carbide blades are recommended for durability and performance. They maintain sharpness longer and deliver cleaner cuts.

FAQ 8: Can I use the same blade for different materials?

No, it’s best to use specific blades for different materials to achieve optimal results. Each material has unique cutting requirements.

FAQ 9: What happens if I don’t adjust for a new blade?

Failing to adjust the fence and blade height may lead to inaccurate cuts and increased risk of kickback. Proper setup is essential for both safety and quality.

FAQ 10: Is it worth upgrading my compact saw’s blade?

Yes, upgrading the blade can significantly improve your cutting experience. It enhances efficiency and can extend the life of your saw.

How Noisy Are Compact Table Saws During Prolonged Use?

FAQ on Noise Levels of Compact Table Saws

1. How loud are compact table saws during use?

Compact table saws typically produce noise levels ranging from 85 to 100 dB, influenced by the motor size and the load during operation.

2. What types of sounds can I expect from a compact table saw?

Users will primarily hear a steady mechanical hum along with blade whine, which can be quite noticeable during extended use.

3. Does prolonged use of a compact table saw lead to ear fatigue?

Yes, the continuous exposure to the saw’s noise can lead to ear fatigue and decreased concentration over time, making hearing protection advisable.

4. What factors can affect the perceived loudness of a compact table saw?

Perceived loudness can be influenced by vibration, the type of material being cut, and the saw’s operational conditions.

5. How can I reduce noise levels while using a compact table saw?

To minimize noise, consider using anti-vibration pads, cleaner blades, or opting for quieter motors designed for reduced sound output.

6. Is regular maintenance important for noise levels?

Absolutely. Regular maintenance of the saw can help prevent sound levels from increasing and ensure optimal performance.

7. Should I wear hearing protection when using a compact table saw?

Yes, wearing hearing protection is recommended to safeguard against potential hearing damage from prolonged exposure to the saw’s noise.

8. Can the material being cut affect the noise level?

Yes, the type of material being cut can impact the noise produced, with different materials generating varying levels of sound during the cutting process.

9. What role do anti-vibration pads play in noise reduction?

Anti-vibration pads can help absorb some of the vibrations generated by the saw, leading to a decrease in the overall noise experienced during use.

10. Are all compact table saws equally noisy?

No, the noise levels can vary significantly between different models based on motor design, size, and features aimed at reducing sound.

What Maintenance Schedule Keeps Compact Saws Accurate Long-Term?

1. How often should I inspect my compact saw?

You should inspect your compact saw weekly to ensure optimal performance. This includes checking for dust accumulation, blade sharpness, and fence alignment.

2. What weekly maintenance tasks should I perform?

Weekly tasks include clearing dust from the saw, checking the sharpness of the blade, and verifying the alignment of the fence to maintain accuracy.

3. What should I clean monthly on my compact saw?

Monthly maintenance involves cleaning the arbor and motor vents, lubricating gears and trunnions, and testing the blade’s perpendicularity using a square.

4. How often should I replace the blade on my compact saw?

You should replace worn blades every six months to ensure clean and accurate cuts. Regularly check the blade condition to avoid performance issues.

5. What maintenance is required every six months?

Every six months, check the belt tension, replace worn blades, and tighten any fasteners to maintain the saw’s reliability and accuracy.

6. What should I do annually for my compact saw?

Annually, perform a full alignment of the saw, inspect the bearings for wear, and consider professional service if you experience persistent drift during cuts.

7. How can I verify the blade’s perpendicularity?

To verify the blade’s perpendicularity, use a square to check the angle between the blade and the table. This should be done monthly to ensure cut accuracy.

8. What is the importance of lubricating gears and trunnions?

Lubricating gears and trunnions monthly helps reduce friction and wear, enhancing the saw’s performance and extending its lifespan.

9. Why is it important to check belt tension?

Checking belt tension every six months is crucial for maintaining proper power transfer to the blade, which affects cutting efficiency and accuracy.

10. When should I consider professional service for my compact saw?

If you notice persistent drift or alignment issues that you cannot resolve through regular maintenance, it’s advisable to seek professional service annually.

Are There Compatible Mobile Stands or Carts for These Models?

1. Are there compatible mobile stands for my saw model?

Yes, many saw models have compatible mobile stands available, including both manufacturer-made and aftermarket options.

2. What should I check to ensure a mobile stand fits my saw?

It’s important to verify the mounting patterns, weight capacity, and any quick-release or folding features to ensure compatibility with your saw’s design.

3. Why is wheel quality important for mobile stands?

Wheels, brake locks, and tilt mechanisms enhance mobility and stability in the shop, making it crucial to choose a stand with reliable features for safe operation.

4. How do I ensure my workspace accommodates the mobile stand?

Measure your workspace before purchasing, and confirm that the stand’s footprint fits well within your available area.

5. What should I look for in terms of durability?

Opt for mobile stands with steel frames, as they provide long-term durability and stability for your saw.

6. How do I confirm bolt-hole alignment?

Before purchasing a mobile stand, check the bolt-hole configuration on your saw to ensure it aligns properly with the stand.

7. Are there specific features I should prioritize for safety?

Look for features like brake locks and sturdy construction, as they contribute to the overall safety of using a mobile stand in your workshop.

8. Can I use aftermarket mobile stands with my saw?

Yes, aftermarket mobile stands can be compatible, but it’s essential to double-check specifications and features before making a purchase.

9. What benefits do quick-release mechanisms offer?

Quick-release mechanisms allow for easier setup and teardown, making it convenient to move your saw in and out of use.

10. Is weight capacity important when choosing a mobile stand?

Absolutely. Ensure that the mobile stand’s weight capacity exceeds your saw’s weight for optimal safety and stability.

Can I Install a Dado Stack Safely on These Compact Saws?

1. Can I install a dado stack on a compact table saw?

Yes, some compact table saws allow for the installation of a dado stack, but it’s essential to check the manufacturer’s guidelines.

2. What should I check before using a dado stack?

Verify the manufacturer’s recommendations regarding motor horsepower, arbor diameter, and maximum blade width, as some saws may have limitations.

3. Will using a dado stack void my warranty?

Using a dado stack on certain saws might void the warranty, so consult your saw’s manual or dealer for specific information.

4. What type of insert do I need for a dado stack?

Make sure to use an appropriate dado insert to ensure proper fit and safety during operation.

5. How can I ensure safety while using a dado stack?

Always implement anti-kickback measures and check the fence alignment to maintain safety while operating.

6. What if I’m unsure about using a dado stack?

If you’re uncertain about installing or using a dado stack, refer to the user manual or consult the dealer for guidance.

7. Are there alternatives to using a dado stack?

Yes, consider using a router-based dado for safer and more controlled results if your saw is not compatible with a dado stack.

8. What is the importance of throat plate clearance?

Throat plate clearance is crucial for the safe installation of a dado stack, as it prevents binding and ensures smooth cuts.

9. How does motor horsepower affect dado stack use?

The motor horsepower determines the saw’s ability to handle the additional load from a dado stack; insufficient power may lead to poor performance or damage.

10. Is there a maximum width for dado blades?

Yes, each compact saw has a maximum width limit for dado blades, so it’s important to verify this specification before use.

11. What is the role of fence alignment in using a dado stack?

Proper fence alignment is essential for accurate cuts and to prevent kickback, making it a vital step before operating with a dado stack.

Final Thoughts

You’ve seen compact, powerful table saws that suit tight shops and varied projects, so choose the one that matches your workflow and storage needs. Prioritize motor power, rip capacity, safety features, and dust control, and don’t forget portability if you move between jobsites. With the right balance of precision and convenience, you’ll get reliable cuts without sacrificing bench space, letting you focus on craftsmanship and efficiency as your projects get more ambitious.